Headers

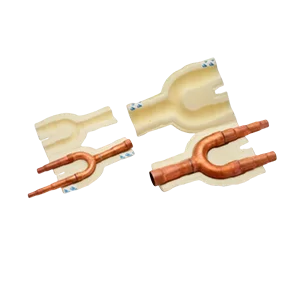

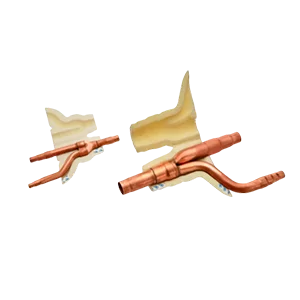

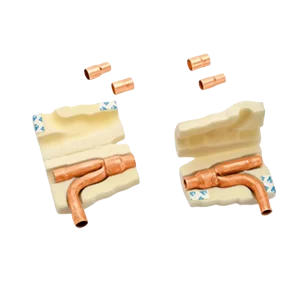

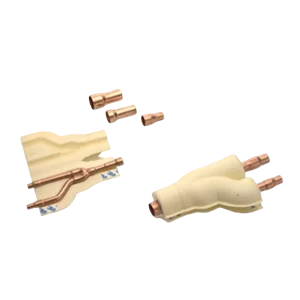

Customized insulation

sam Series

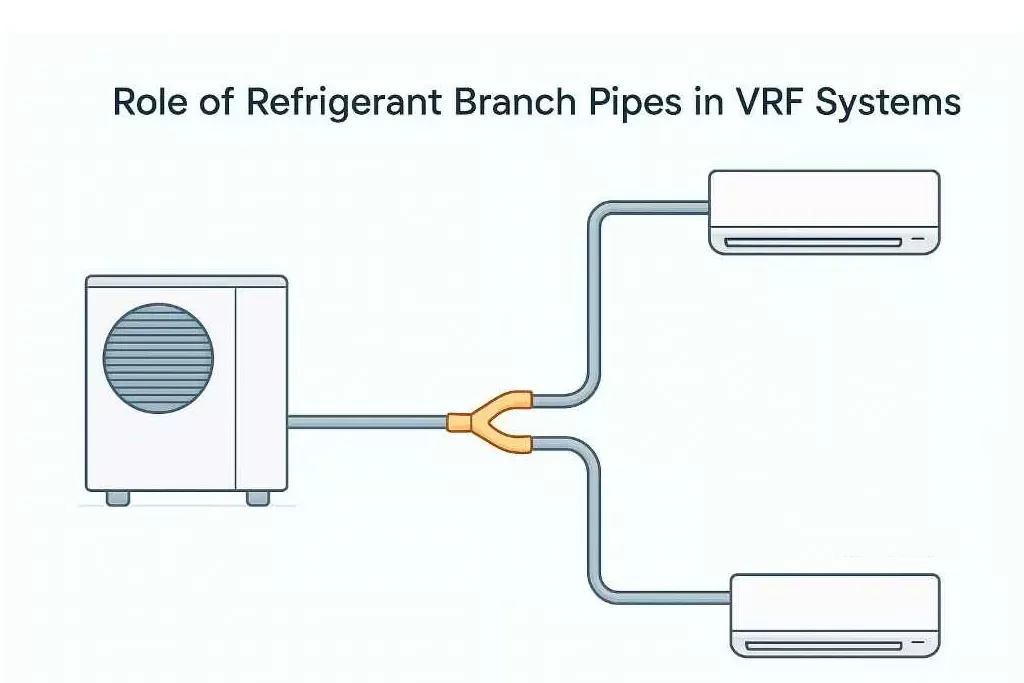

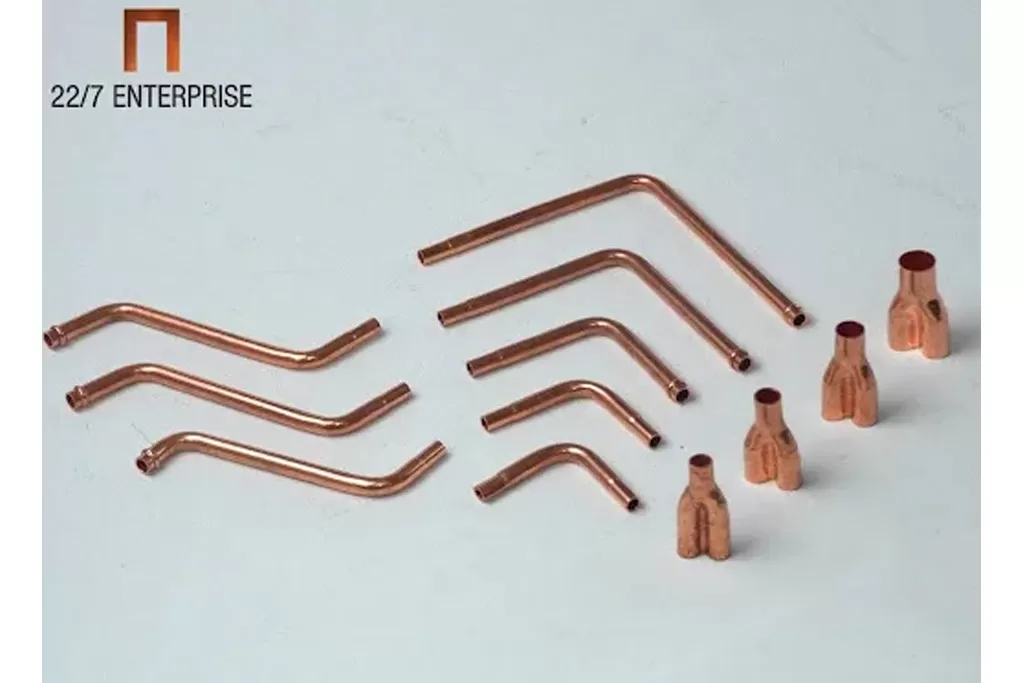

Refrigerant Branch Piping Kit for all types of VRF Systems working on R410 Refrigerant

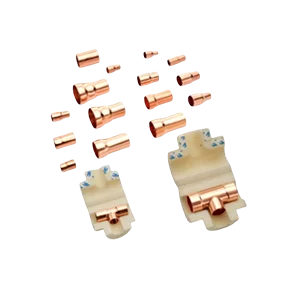

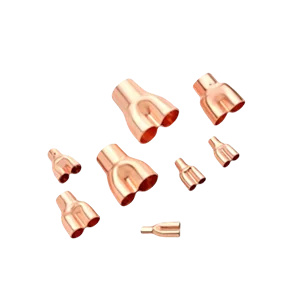

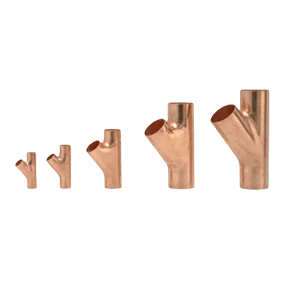

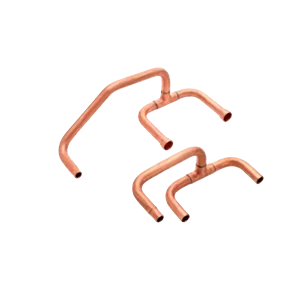

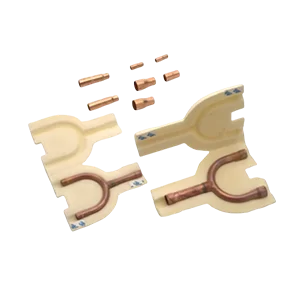

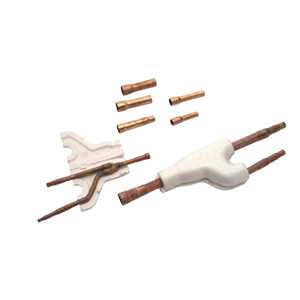

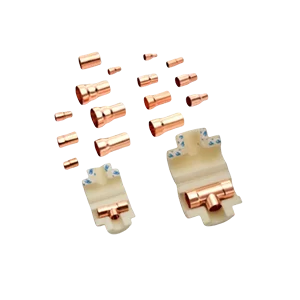

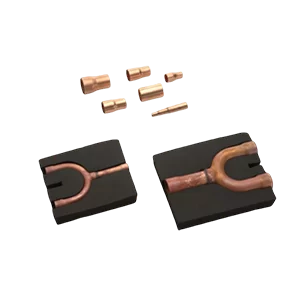

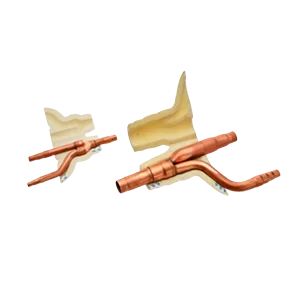

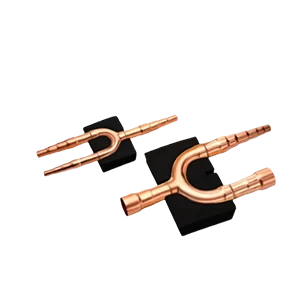

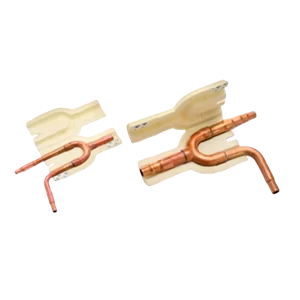

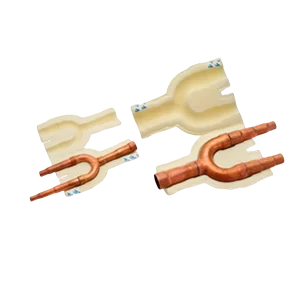

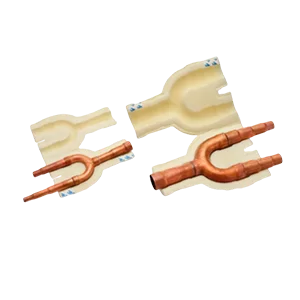

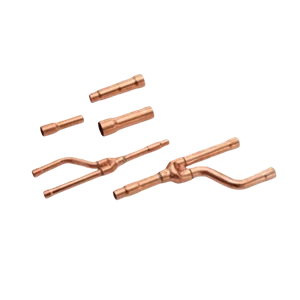

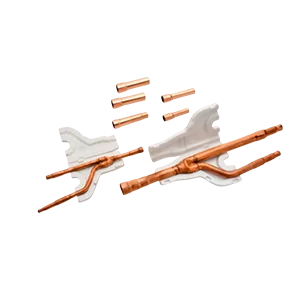

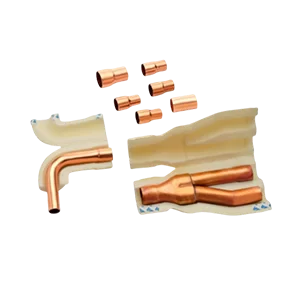

227 Enterprise Pvt. Ltd. manufactures SAM Series VRF Branch Piping Kits with two copper Y-joints for secure refrigerant flow and system compatibility. Uniform bodies with multi-step reducing attachments allow direct size selection, making field brazing quicker, accurate, and easier while ensuring dependable connections across varied VRF piping layouts.

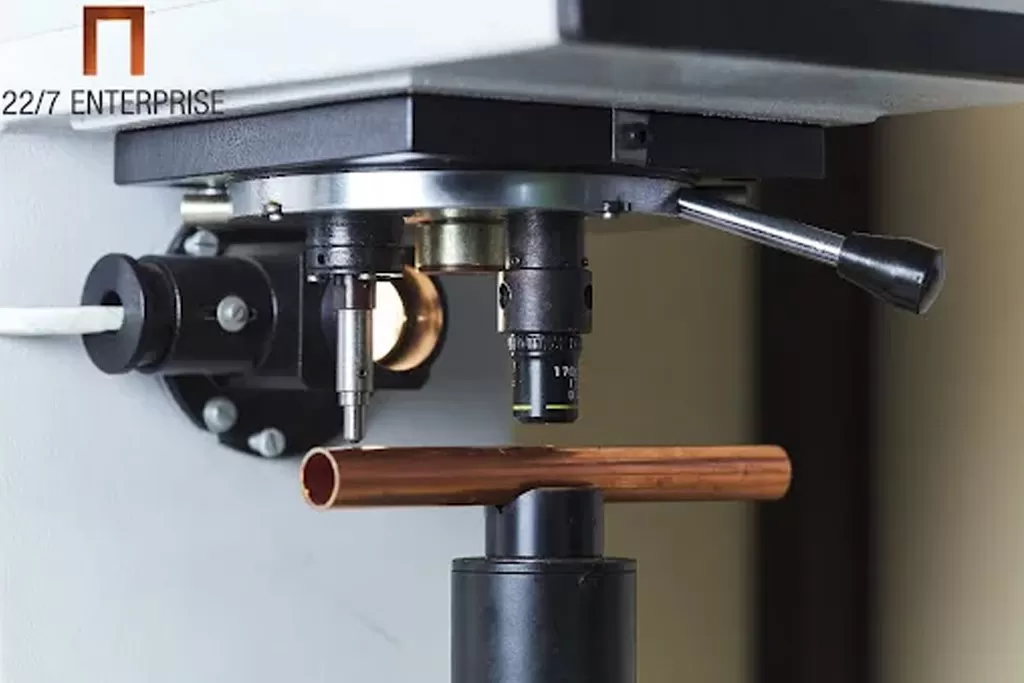

Each SAM Series VRF Branch Piping Kit is hydrostatically tested at 5.2 MPa and inspected through multiple quality stages to ensure leak-free reliability and consistent system performance. Manufactured from precision-engineered copper components, these assemblies maintain smooth refrigerant flow, limit pressure drop, and help extend the overall service life of VRF installations across demanding project conditions and applications.

sam

Series

FEATURES OF sam series

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE Compliant

Robust Design

Product specification

| Model | Pipe | Pipe A (ID) | Pipe B (ID) | Pipe C (ID) | Reducers Numbers & Qty |

|---|---|---|---|---|---|

| Pi-YA1509M | Gas Side | 15.88 (5/8) – 19.05 (3/4) | 19.05 (3/4) | 19.05 (3/4) | 2 X 2 Nos |

| Liquid Side | 9.52 (3/8) – 12.7 (1/2) | 12.7 (1/2) | 12.7 (1/2) | 1 X 2 Nos | |

| Pi-YA2512M | Gas Side | 19.05 (3/4) – 22.22 (7/8) – 25.4 (1) | 25.4 (1) | 25.4 (1) | 3 X 2 Nos, 8 X 2 Nos |

| Liquid Side | 9.52 (3/8) – 12.7 (1/2) | 12.7 (1/2) | 12.7 (1/2) | 1 X 2 Nos | |

| Pi-YA2812M | Gas Side | 31.8 (1-1/4) – 28.58 (1-1/8) | 31.8 (1-1/4) | 31.8 (1-1/4) | 3 X 1 Nos, 7 X 1 Nos |

| Liquid Side | 9.52 (3/8) – 12.7 (1/2) | 12.7 (1/2) | 12.7 (1/2) | 1 X 2 Nos | |

| Pi-YA2815M | Gas Side | 31.8 (1-1/4) – 28.58 (11/8) | 31.8 (1-1/4) | 31.8 (1-1/4) | 3 X 1 Nos, 7 X 1 Nos |

| Liquid Side | 15.88 (5/8) – 19.05 (3/4) | 19.05 (3/4) | 19.05 (3/4) | 2 X 2 Nos | |

| Pi-YA3419M | Gas Side | 31.8 (1-1/4) – 34.9 (1-3/8) – 38.1 (1-1/2) | 34.9 (1-3/8) | 34.9 (1-3/8) | 9 X 1 Nos, 10 X 1 Nos, 12 X 1 Nos |

| Liquid Side | 15.88 (5/8) – 19.05 (3/4) | 19.05 (3/4) | 19.05 (3/4) | 2 X 2 Nos, 11 X 2 Nos | |

| Pi-YA4119M | Gas Side | 41.2 (1-5/8) – 38.10 (1-1/2) | 38.1 (1-1/2) | 34.9 (1-3/8) | 3 X 1 Nos, 5 X 1 Nos, 9 X 1 Nos, 12 X 1 Nos |

| Liquid Side | 15.88 (5/8) – 19.05 (3/4) | 19.05 (3/4) | 19.05 (3/4) | 2 X 2 Nos, 11 X 2 Nos | |

| Pi-YA4422M | Gas Side | 41.2 (1-5/8) – 44.4 (1-3/4) – 54.1 (2-1/8) | 41.2 (1-5/8) | 38.1 (1-1/2) | 3 X 1 Nos, 4 X 1 Nos, 5 X 1 Nos, 6 X 1 Nos |

| Liquid Side | 19.05 (3/4) – 22.22 (7/8) – 25.4 (1) | 25.4 (1) | 25.4 (1) | 3 X 2 Nos, 1 X 1 Nos |

Reducer Number & Size

| 1 | 6.35 (1/4) ID X 9.52 (3/8) ID X 12.7 (1/2) OD | 7 | 15.88 (5/8) ID X 22.22 (7/8) ID X 25.4 (1) ID X 28.58 (1 1/8) OD |

| 2 | 6.35 (1/4) ID X 9.52 (3/8) ID X 12.7 (1/2) ID X 15.88 (5/8) ID X 19.05 (3/4) OD | 8 | 28.58 (1-1/8) ID X 25.4 (1) OD |

| 3 | 12.7 (1/2) ID X 15.88 (5/8) ID X 19.05 (3/4) ID X 22.22 (7/8) ID X 25.4 (1) OD | 9 | 25.4 (1) ID X 28.58 (1-1/8) ID X 31.8 (1-1/4) ID X 34.9 (1-3/8) OD |

| 4 | 28.58 (1-1/8) ID X 31.8 (1-1/4) ID X 38.10 (1-1/2) ID X 41.2 (1-5/8) OD | 10 | 12.7 (1/2) ID X 15.88 (5/8) ID X 19.05 (3/4) ID X 22.22 (7/8) ID X 25.4 (1) ID X 28.58 (1-1/8) OD |

| 5 | 25.4 (1) ID X 28.58 (1-1/8) ID X 31.8 (1-1/4) ID X 38.10 (1-1/2) OD | 11 | 22.22 (7/8) ID X 19.05 (3/4) OD |

| 6 | 54.1 (2-1/8) ID X 44.4 (1-3/4) ID X 41.2 (1-5/8) OD | 12 | 41.2 (1-5/8) ID X 38.10 (1-1/2) OD |

OUR Products

Universal

Branch Pipe

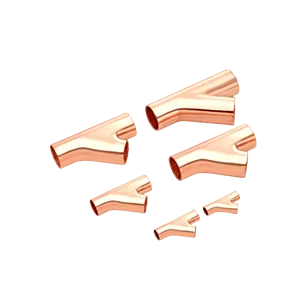

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

ME

Series

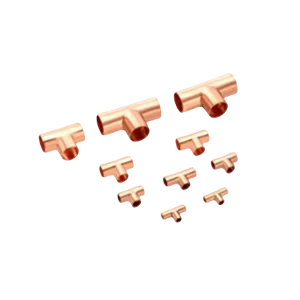

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

AX

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

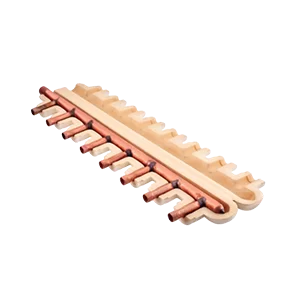

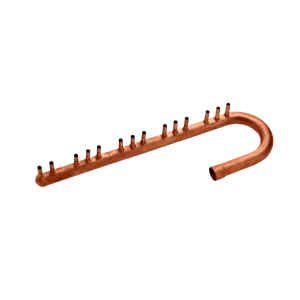

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

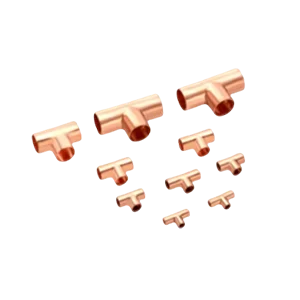

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The SAM Series' multi-step design cut our VRF piping installation time by 20% on a high-rise project, with zero leak call-backs.

Project Manager, Major Construction Firm,

IndiaUsing 227's SAM kits standardized our inventory across different OEM brands, simplifying procurement and reducing costs.

Procurement Head, MEP Consultancy,

Saudi ArabiaThe leak-proof guarantee gave us the confidence to specify 227 Enterprise for a critical hospital HVAC project.

HVAC Design Consultant, Engineering Firm,

UAESwitching to their pre-tested SAM Series kits has virtually eliminated post-installation refrigerant leaks in our systems.

Service Director, HVAC Contractor,

QatarThe technical support and OEM compatibility data provided made system design and specification straightforward.

Lead Engineer, Building Services Firm,

OmanOur Blogs

FAq's

What is the main benefit of the multi-step design of the SAM Series?

The multi-step copper fixing brazed to the Y-joint allows installers to cut to the required size of the pipe on location. This ensures the ideal fit to any OEM connection, expedites installation, and removes several different reducer fittings- thus minimizing brazing points and possible sources of leakages.

Do SAM Series kits work with the major VRF brands?

Yes. The SAM Series is designed to be universally compatible. The multi-step design and supplied reducers fit perfectly with the standard pipe sizes all major VRF/VRV OEMs use, and is a flexible single-inventory solution to contractors in various brands.

What is the 5.2MPa pressure testing that ensures the system is leak-proof?

Each SAM Series joint is tested to hydrostatic pressure at 5.2 Mpa (approximately 754 psi), which is many times higher than the typical VRF operating pressure. This 100 percent testing technique is used to find out any possible weaknesses in the factory; a perfect seal and long-term stability of the kit are achieved before the kit goes to the job site.

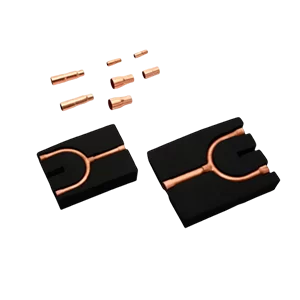

What are the insulation choices on the SAM Series Branch Piping Kits?

We provide high-end insulation to meet the needs of different projects and safety standards:

- Fire Grade XLPE to achieve better fire retardancy.

- Class O Nitrile Butadiene Rubber (NBR) with high thermal efficiency, moisture and elasticity.

Does 227 Enterprise produce these VRF components or does it sell them?

We are a high-grade manufacturer. 227 Enterprise designs, engineers, and manufactures the SAM Series within our premises. This provides us with total quality control, whether it is raw copper, or final test and enables us to provide real expertise and personal support and custom solutions that the distributors cannot.

Do you offer custom-designed kits on special project layouts?

Absolutely. Being a speciality manufacturer, we regularly distribute custom-designed VRF Branch Piping Kits, such as special header assemblies, special joint angles, or custom-designed insulation needs. With your specifications, our engineering team collaborates directly with you to produce components that meet the exact design requirements of your project.

What are the international export project certifications of your products?

The SAM Series VRF Y Joint is produced as per RoHS requirements, so there are no restricted hazardous substances in it. It also comes with CE marking, which means it meets the safety and environmental expectations followed across the European region, and it’s made to satisfy AS 4041 pressure piping criteria. The manufacturing is done under ISO-controlled processes, and whenever your project calls for it, we can provide the complete set of certificates and supporting documents.

How long does it take to get a standard and custom SAM Series kit order?

Standard kits are normally in stock and can be shipped immediately. Custom orders have different lead times depending on the complexity and are well articulated after the technical specifications have been agreed upon. To ensure your project is on schedule,e we are concerned about efficient production.

Does your product have a warranty, and what is your technical support?

Yes. We have a wide-ranging warranty on the manufacturing defects of our products. We also give direct technical support, such as compatibility questions, best practices in installation, and system integration to make the project successful.

What is the overall effect of the use of the SAM Series kit on the efficiency and life of the VRF system?

Our kits maintain the intended refrigerant flow and system pressure by providing accurate and leak-free connections with low pressure drop. This safeguards the compressor, ensures the best heat-exchange performance, minimizes power use and has a direct impact on the long-term dependability and life span of the whole VRF system.