VRF

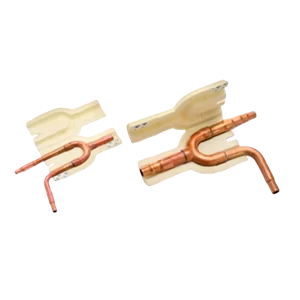

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

- AX Series

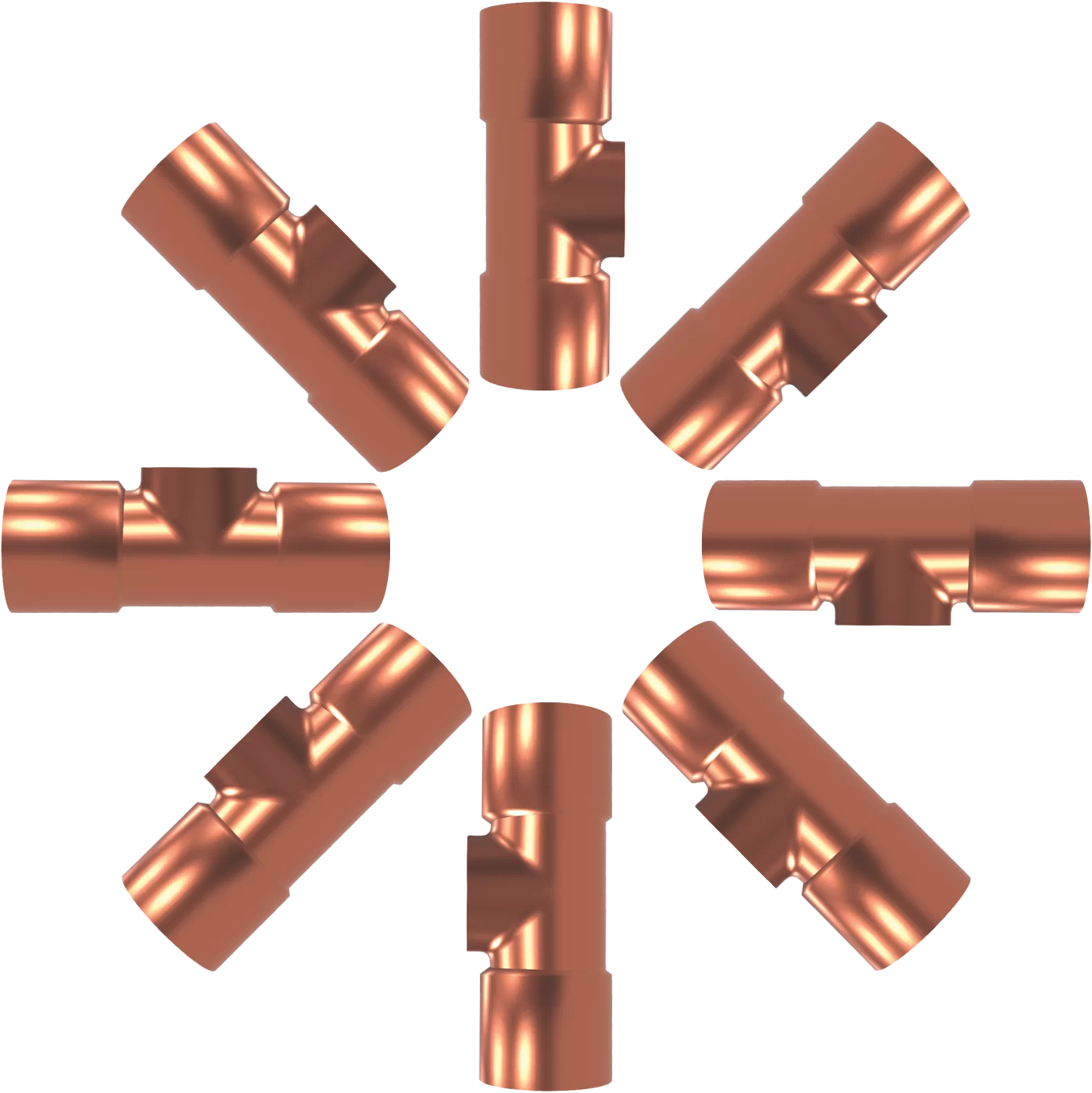

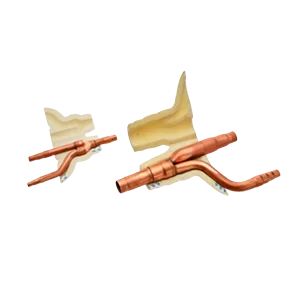

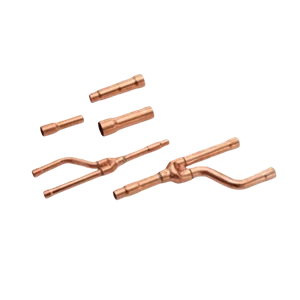

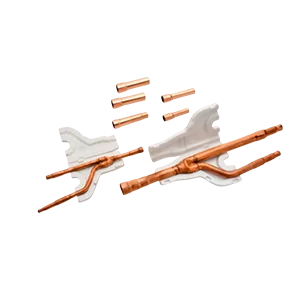

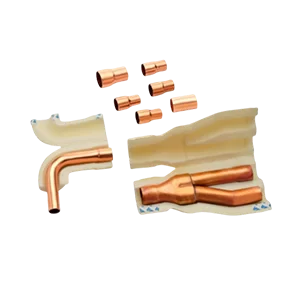

- VRF Y Joint

- VRF Branch Piping

- VRF Refrigerant Branch Piping

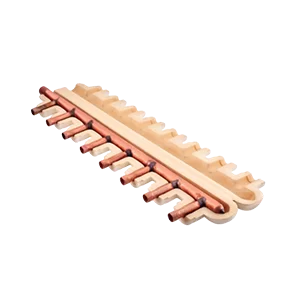

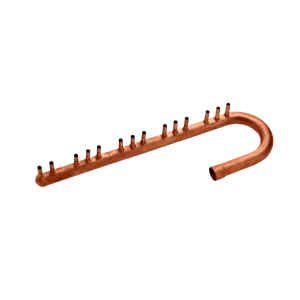

Headers

- SAM Headers

- TA Headers

- Customized Headers

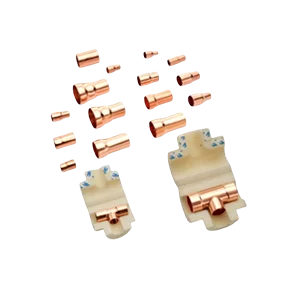

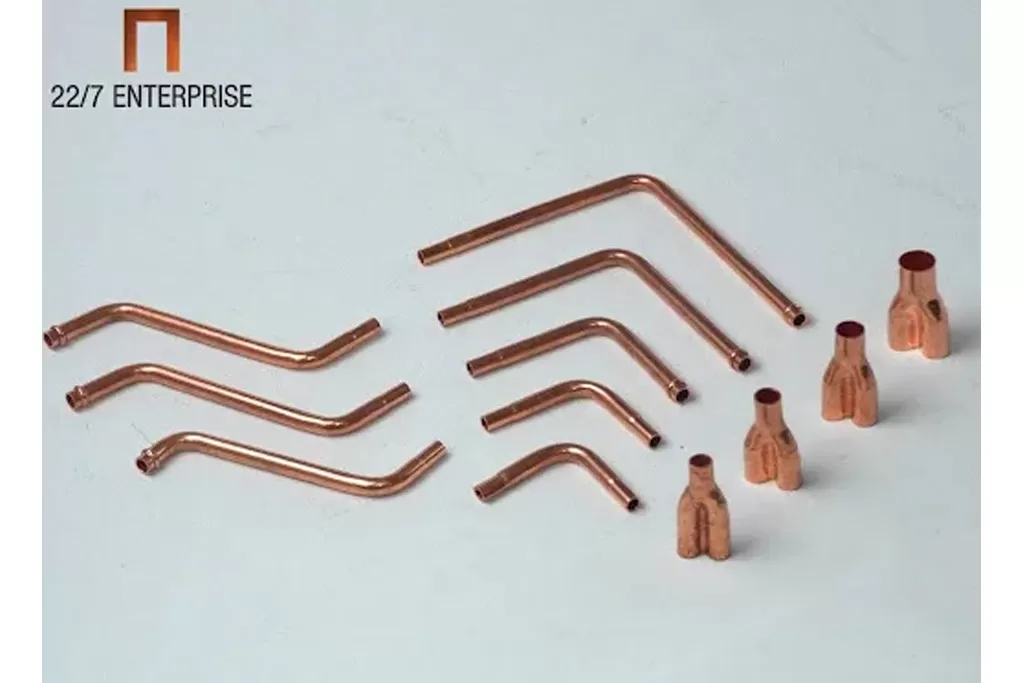

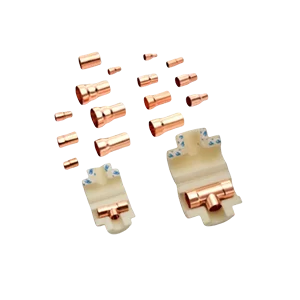

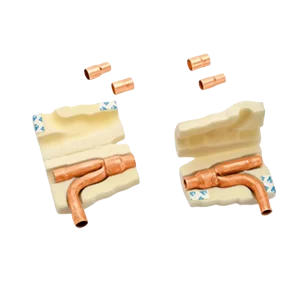

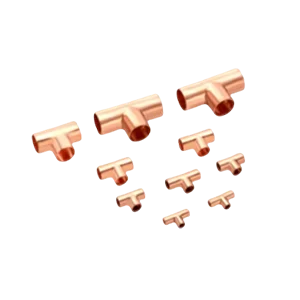

Copper Components

- Copper Compression T Fitting

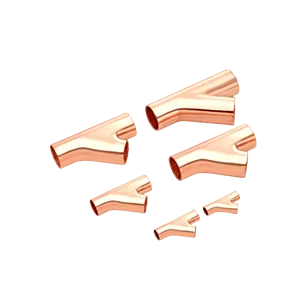

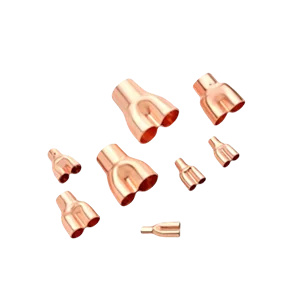

- Copper Y Fitting

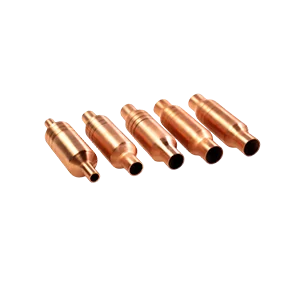

- Strainers

- Mufflers

- Stubs

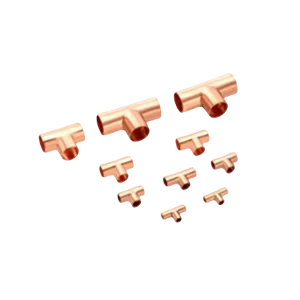

- Commercial Tee's

- Copper Tee Joint

- Y-Type Distributors

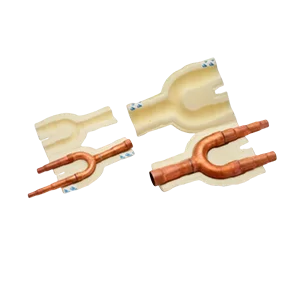

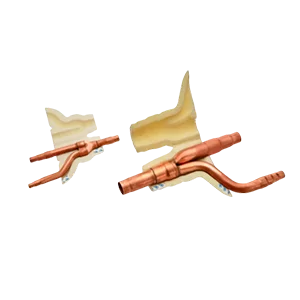

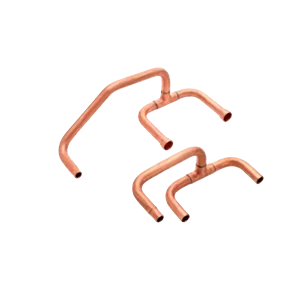

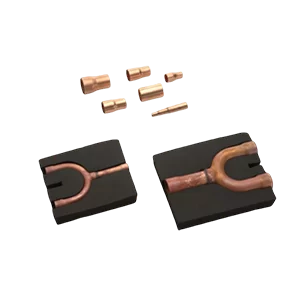

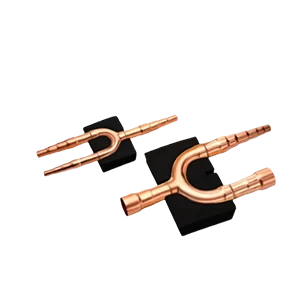

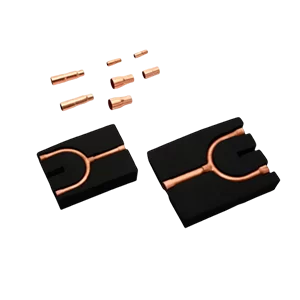

- Unbrazed U & Y Fittings

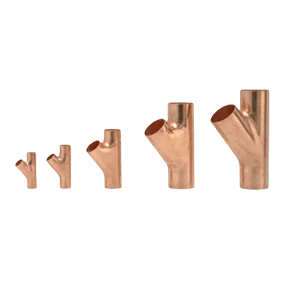

- Copper Y-Joint

- Tubular Assemblies

Customized insulation

NBR Insulation

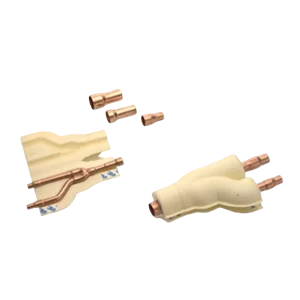

Nitrile Butadiene Rubber Insulation for VRF Refrigerant Branch Piping Kits

227 Enterprise Pvt Ltd delivers NBR insulation engineered for VRF and VRV Y branch joints, combining flexibility, thermal stability, and dependable fire safety. Proven across demanding European installations, it meets strict quality needs while enhancing HVAC output for critical climate control projects today.

Rated ASTM E84 25/50, our AP Armaflex grade insulation helps control flame spread and smoke. With CNC laser routing, every section is cut to suit intricate VRF Y joint shapes, giving a clean, accurate fit at site. The precise profiling reduces trimming, improves finish, and supports consistent thermal performance.

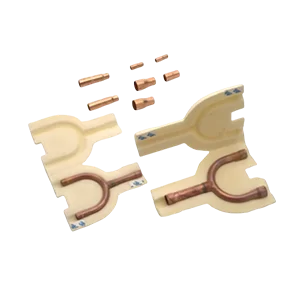

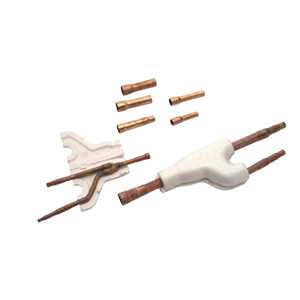

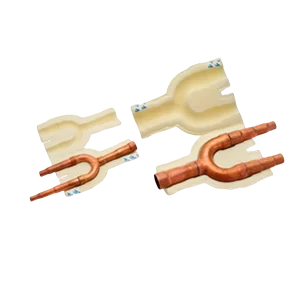

DA Series

With NBR

FEATURES OF DA Series With NBR

Ease of Installation

CE Marking

FR Grade

Moisture & Weather Resistant

RoHs Compliant

Product specification

| Pipe-A | Pipe-B | Pipe-C | |

|---|---|---|---|

| Pi-KHRP-22T (Gas Side) | 12.7 (1/2) – 15.88 (5/8) – 19.05 (3/4) | 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-22T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35(1/4) | 9.52 (3/8) – 6.35(1/4) |

| Pi-KHRP-33T (Gas Side) | 22.22 (7/8) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-33T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35 (1/4) | 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-72T (Gas Side) | 31.75 (11/4) -28,58 ( 11/8) – 25.4 (1) | 25.4 (1) – 19.05(3/4) – 15.88 (5/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-72T (Liquid Side) | 15.81 (5/8) – 12.7 (1/2) | 12.7 (1/2) – 9.52 (3/8) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-73T (Gas Side) | 38.10 (11/2) – 31.75 (11/4) | 31.75 (11/4) – 28.58 (11/8) – 25.4 (1) | 25.4 (1) – 19.05 (3/4) – 15.88 (5/8) |

| Pi-KHRP-73T (Liquid Side) | 15.88 (5/6) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) |

OUR Products

Universal

Branch Pipe

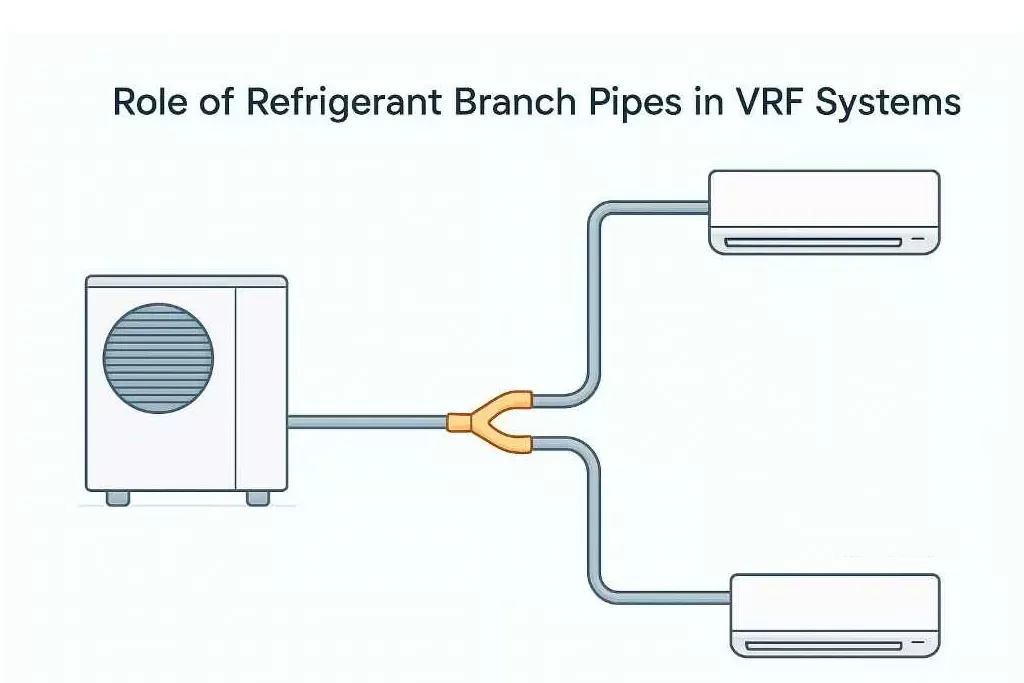

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

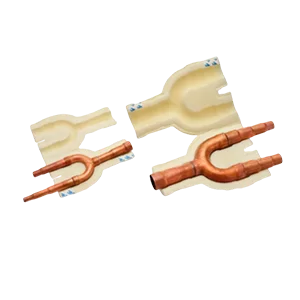

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

AX

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The DA Series NBR Insulation has drastically reduced our installation time and improved system efficiency.

Procurement Head, MEP Consultancy,

Saudi ArabiaExceptional fire safety and thermal performance that meets our stringent project specifications.

Project Manager, HVAC Contractor,

UAEThe Microban protection is a game‑changer for maintaining indoor air quality in our commercial projects.

Technical Director, Building Services Firm,

QatarReliable supplier with consistent quality and timely delivery for our large‑scale VRF installations.

Operations Manager, Real Estate Developer,

IndiaThe RoHS and CE compliance gives us confidence in using these products across European market

Export Manager, HVAC Distributor,

GermanyOur Blogs

FAq's

What is NBR insulation, and why do we need this in VRF systems?

NBR, Nitrile Butadiene Rubber, is a closed-cell foam specifically designed to fit the HVAC pipes. It excludes heat, prevents condensation and is fire-proof. It fits into tricky Y-shaped joints since it is super flexible, and it ensures that the system will operate in the same manner and meet international standards.

What are the major characteristics of NBR Insulation?

The joint can be put in place without any special tools, which makes the job quicker and easier on site. It also has Microban protection to help keep mould from forming, meets the ASTM E84 25/50 Class O fire rating, and follows RoHS and CE requirements. Because it doesn’t let heat pass through easily, it helps cut down energy loss, and at the same time, it remains strong, safe, and well suited for heavy-duty VRF use.

Is NBR fireproofed, and what are the standards of NBR?

Well, it is fireproof, it is basically. We subject it to serious tests, and it was rated ASTM E84 -25/50 -Class O at the top of the categories. That prevents fire from spreading and smog buildup, which provides life-saving personnel with a chance of escape and achieves challenging building standards all over the world.

What is the advantage of the Microban antimicrobial protection to the system?

Microban prevents the sprouting of mould, germs, and bacteria in the foam. It implies cleaner indoor air, prevents the insulation from wearing out, and makes the building feel healthier, which is extremely crucial in both office and home VRF systems.

What are the global market certifications for NBR Insulation?

It holds important approvals like the ASTM E84 fire rating, RoHS compliance for restricted materials, and CE safety marking. In practical terms, these certifications show that the product is built for applications where performance, safety, and regulatory acceptance really matter.

What is the energy efficiency in use of NBR insulation in VRF systems?

Its super-low heat conduct prevents the leakage of hot or cold through the lines. That maintains the refrigerant in the optimal temperature, reduces the load of the compressor and reduces the overall energy consumption. It saves a great deal of money in the long run and makes the entire building run in an easier way.

Is this insulation available for indoor and outdoor uses

Yes, it features a closed-cell design that supports water and UV rays, making it suitable for use outside as well. If it is exposed to the sun throughout the day, we recommend using a UV shield coat. Its germ-blocking and fire-proofing features would provide a little more protection in the house and make the air safer.

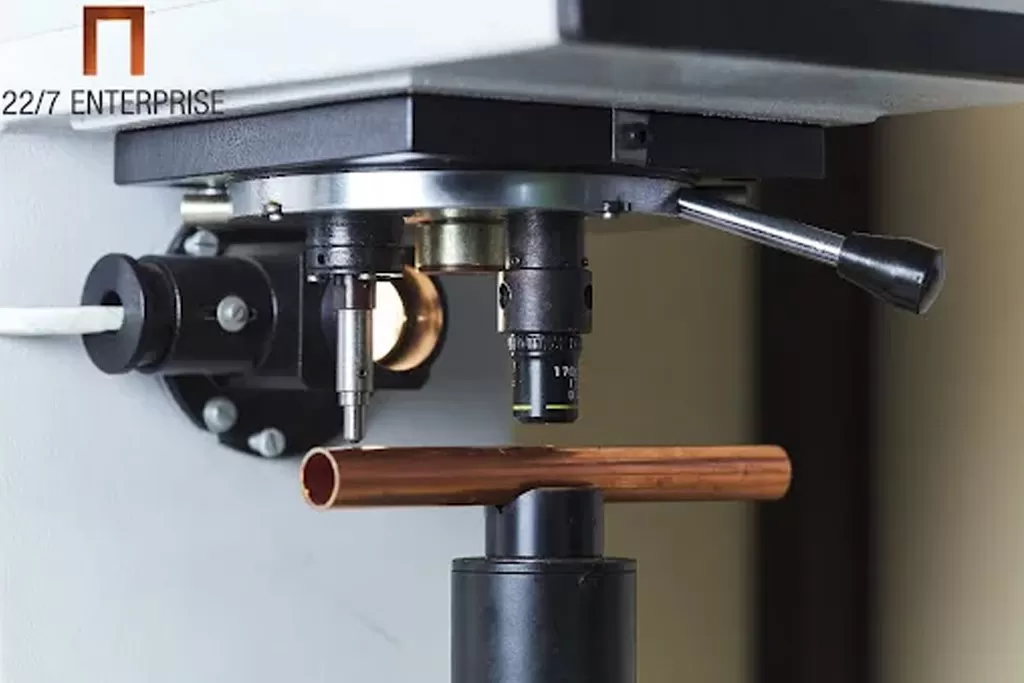

What is the custom-fitting of the insulation to the various VRF Y- joints?

Each bit is laser cut and CNC technology suited to fit precisely the shape of each Y-joint. That will have a snug, seamless fit which is easy to wear and prevents heat and moisture to escape.

What is the projected service life of NBR Insulation?

With proper installation and basic protection from mechanical damage, it can easily serve for 15–20 years. The closed-cell foam doesn’t soak up moisture, doesn’t deteriorate quickly with age, and doesn’t support microbial growth, so its insulation value stays almost the same even after years of use.

Why would NBR Insulation pick 227 Enterprise among the other suppliers?

At 227 Enterprise, we work with high-grade AP ArmaFlex insulation and cut it on CNC and laser routing machines so every piece fits properly without gaps or adjustments on site. The material itself is tested for fire safety and resistance to microbial growth, and it has already proven its performance in real installations. Along with the product, we make sure there’s dependable technical support, regular availability, and consistent quality, so your VRF project can be executed smoothly without unnecessary delays or rework.