VRF

- Universal Branch Pipe

- DA Series

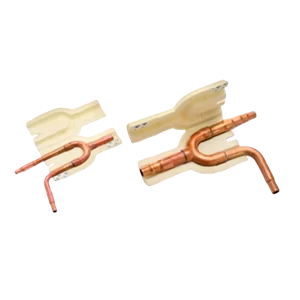

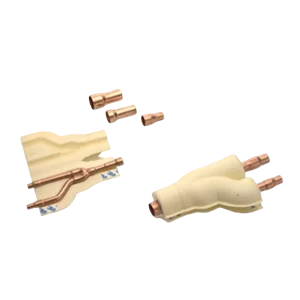

- ME Series

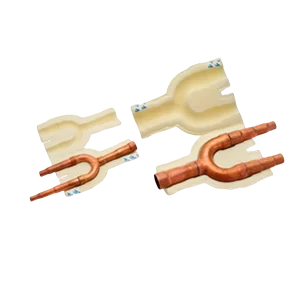

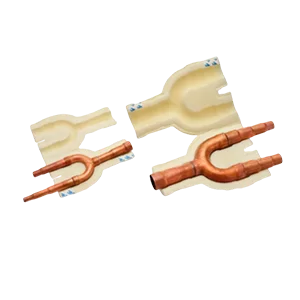

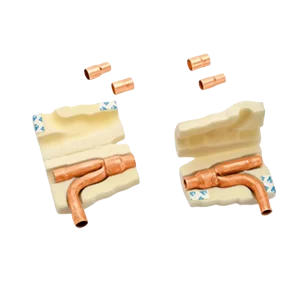

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

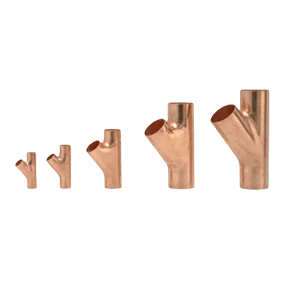

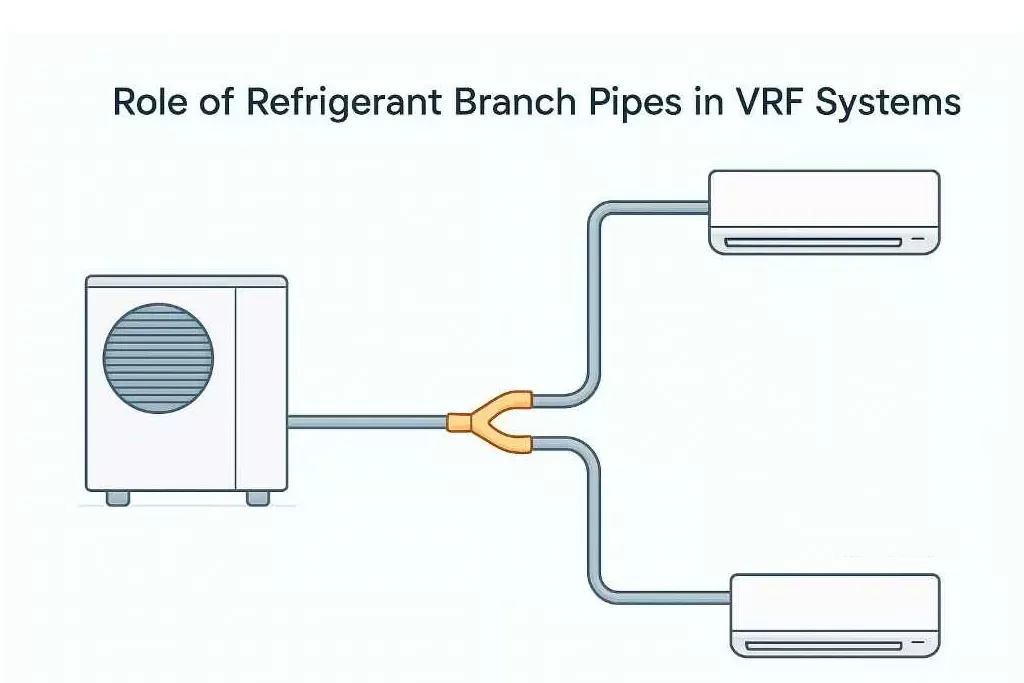

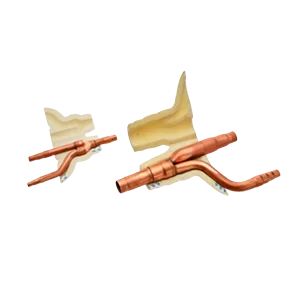

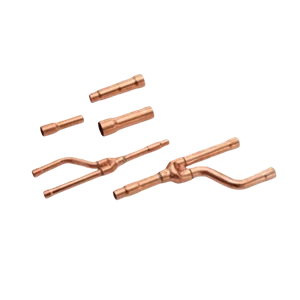

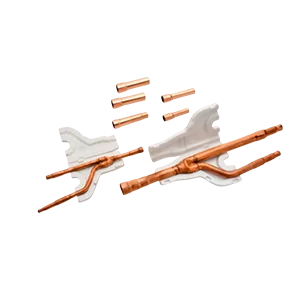

- VRF Y Joint

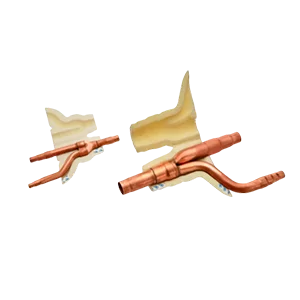

- VRF Branch Piping

- VRF Refrigerant Branch Piping

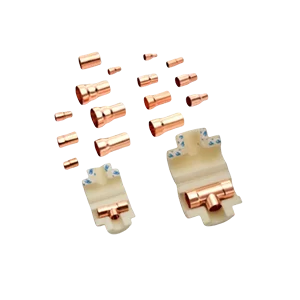

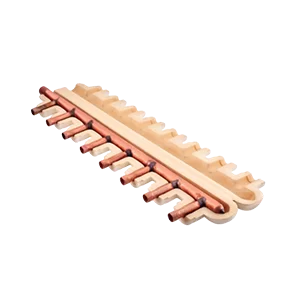

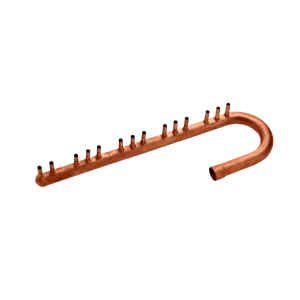

Headers

- SAM Headers

- TA Headers

- Customized Headers

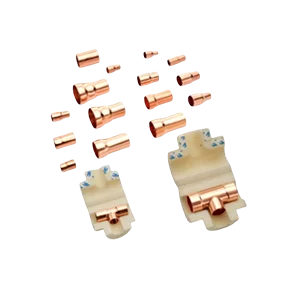

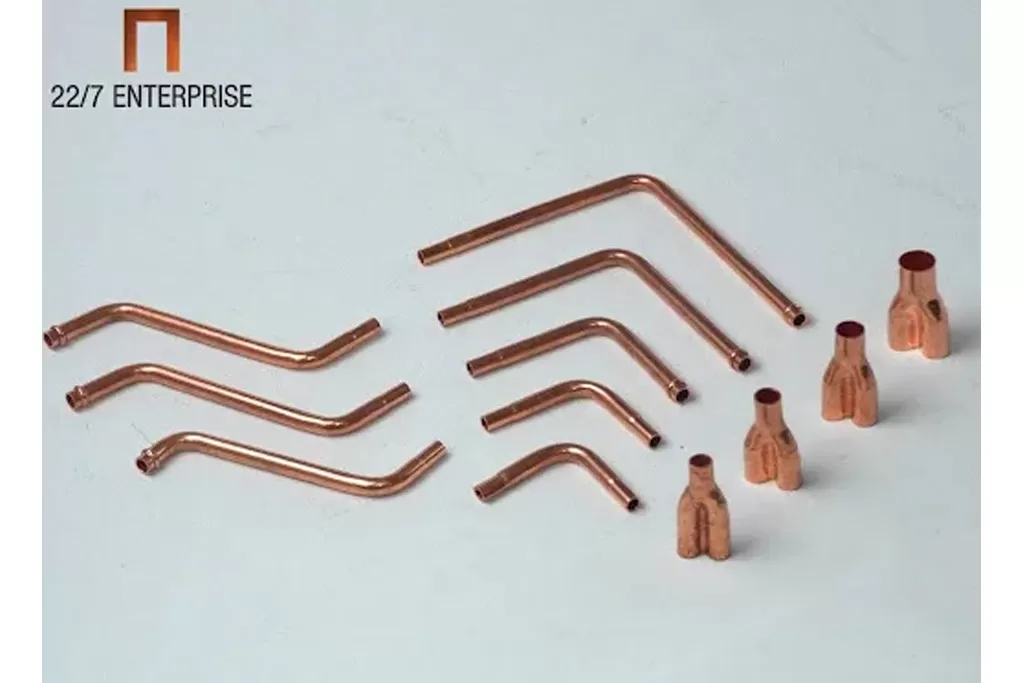

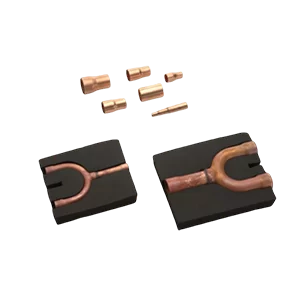

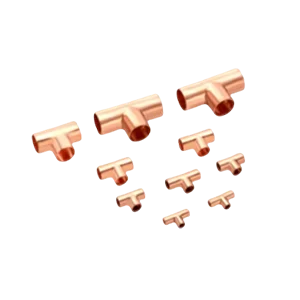

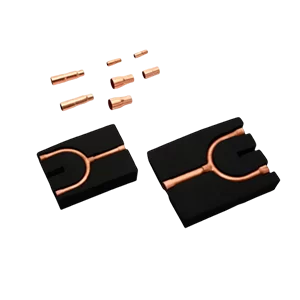

Copper Components

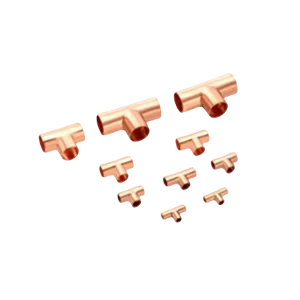

- Copper Compression T Fitting

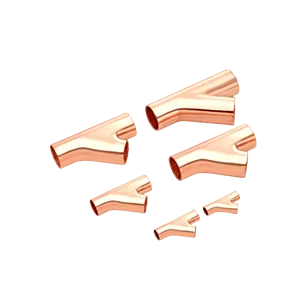

- Copper Y Fitting

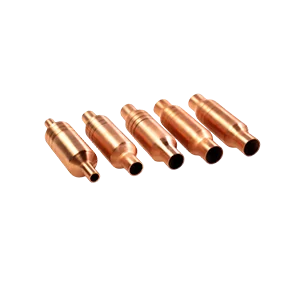

- Strainers

- Mufflers

- Stubs

- Commercial Tee's

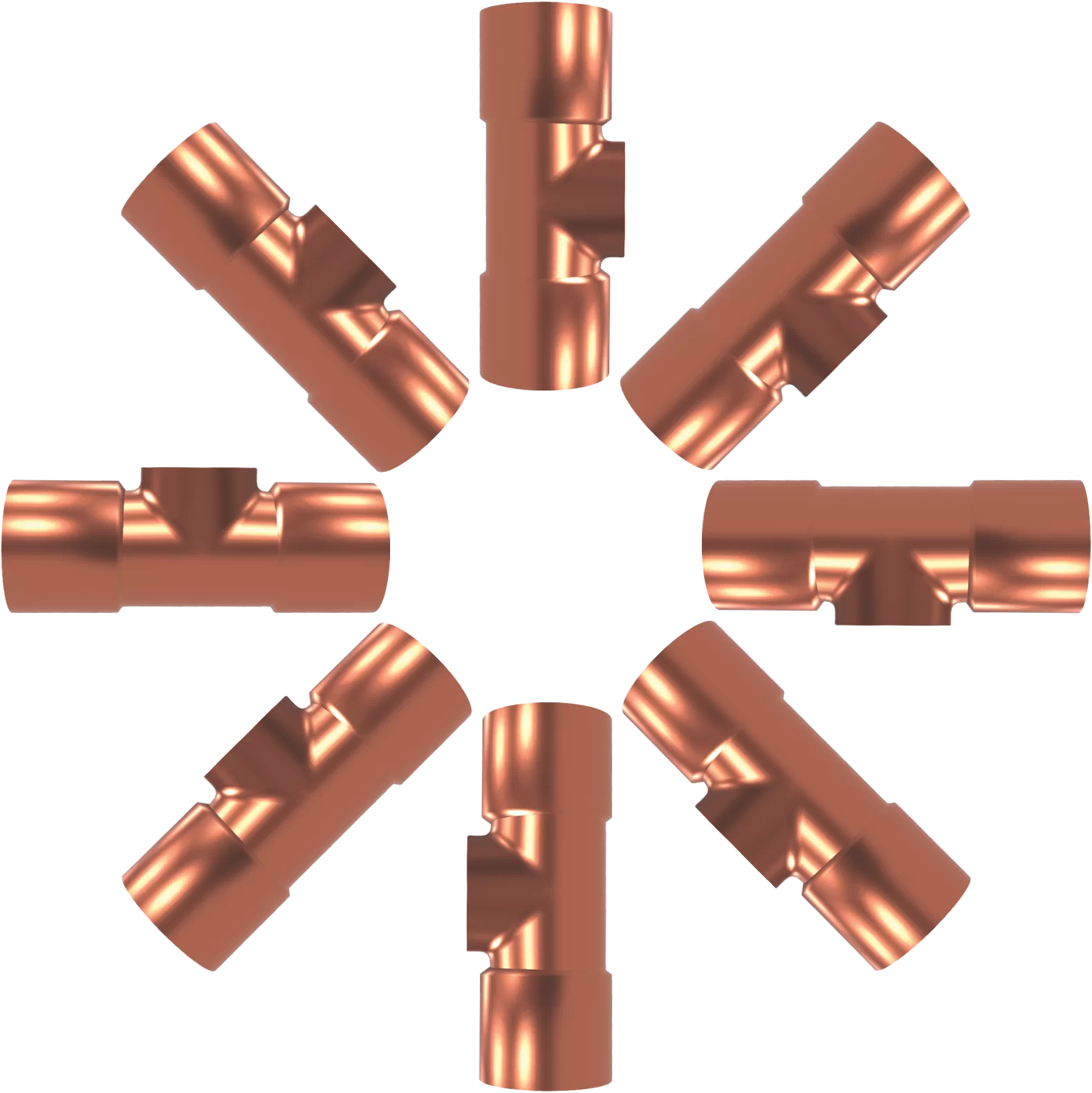

- Copper Tee Joint

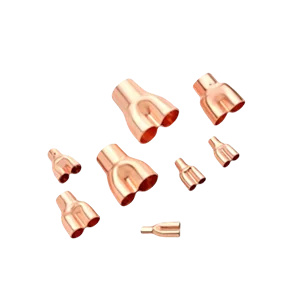

- Y-Type Distributors

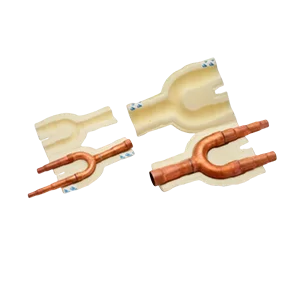

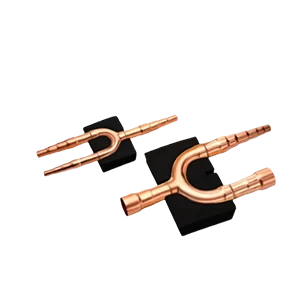

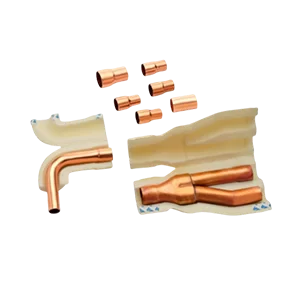

- Unbrazed U & Y Fittings

- Copper Y-Joint

- Tubular Assemblies

Customized insulation

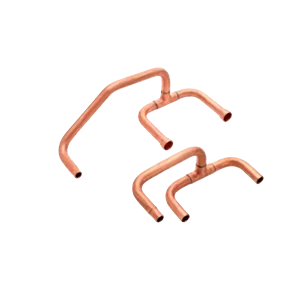

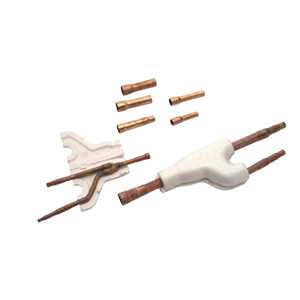

MI Series

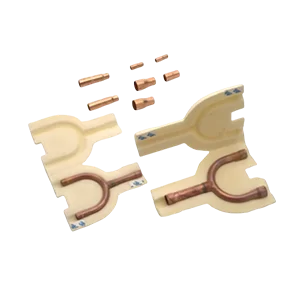

Engineered for High-Performance R410a & Next-Generation Refrigerant VRF Networks

MI

Series

FEATURES OF MI Series

Easy to Install

Pressure Tested at 5.2 MPA

100% leak-proof Construction

RoHS & CE Compliant

Robust Design Built

Product specification

| Pipe-A | Pipe-B | Pipe-C | |

|---|---|---|---|

| Pi-FQZHN-01 (Gas Side) | 19.05 (3/4) – 15.88 (5/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) |

| Pi-FQZHN-01 (Liquid Side) | 12.7 (1/2) – 9.52 (3/8) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) |

| Pi-FQZHN-02 (Gas Side) | 25.4 (1) – 22.2 (7/8) | 22.2 (7/8) – 19.05 (3/4) – 15.88 (5/8) | 22.2 (7/8) – 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) |

| Pi-FQZHN-02 (Liquid Side) | 9.52 (3/8) – 12.7 (1/2) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) |

| Pi-FQZHN-03 (Gas Side) | 31.75 (11/4) – 28.58 (11/8) | 28.58 (11/8) – 22.2 (7/8) – 19.05 (3/4) | 28.58 (11/8) – 22.2 (7/8) – 19.05 (3/4) – 15.88 (5/8) |

| Pi-FQZHN-03 (Liquid Side) | 19.05 (3/4) – 15.88 (5/8) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) |

| Pi-FQZHN-04 (Gas Side) | 38.10 (11/2) – 34.93 (13/8) | 34.93 (13/8) – 28.58 (11/8) – 22.2 (7/8) | 34.93 (13/8) – 28.58 (11/8) – 22.2 (7/8) – 19.05 (3/4) |

| Pi-FQZHN-04 (Liquid Side) | 22.2 (7/8) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) |

OUR Products

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

Switching to 227's MI Series eliminated call-backs for leaks on our high-rise projects.

Project Director, Luxury Real Estate Developer,

UAEThe traceability coding gives our clients unmatched confidence in system quality.

Chief Engineer, Five-Star Hotel Chain,

IndiaThe fit is perfect, OEM to renowned brands, making our procurement streamlined.

Head Procurement, MEP Consultancy,

Saudi ArabiaHigh-quality insulation that does not sweat even in the north-east windy coast.

Operations Manager, Mall Management Group,

Southeast Asia.On-time delivery and reliable performance make our large-scale projects on time.

Technical Manager, Government Infrastructure Agency,

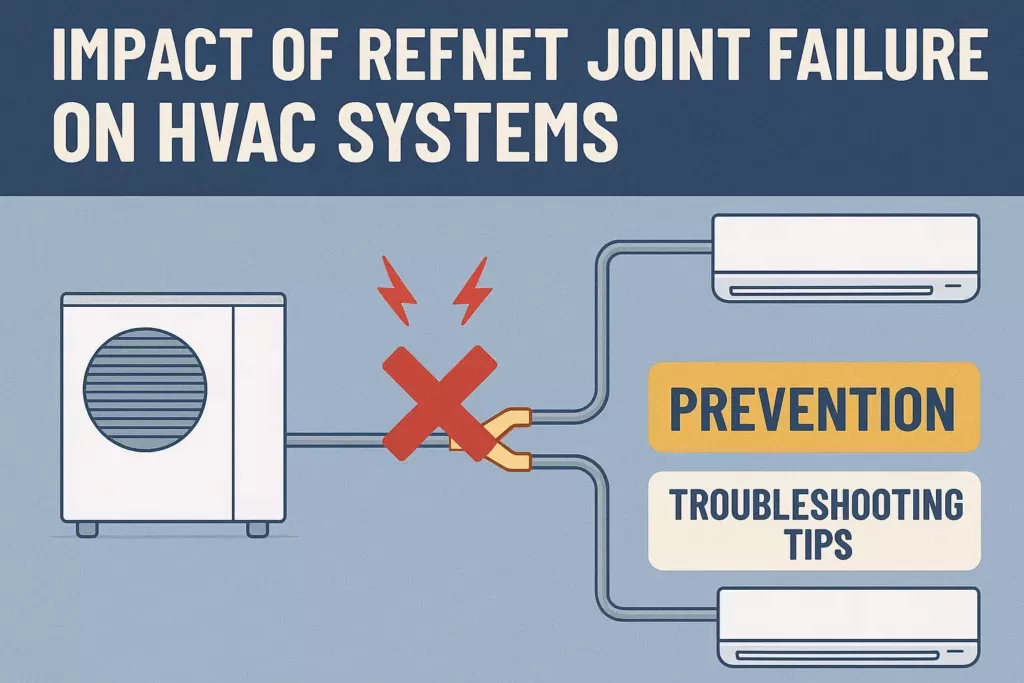

QatarOur Blogs

FAq's

Does MI Series work with all major VRF/VRV OEM brands?

Yes, MI Series is accuracy-designed to be fully compatible with all major VRF/VRV systems. Our joints meet exact OEM specifications to ensure seamless integration, optimal refrigerant flow, and reliable performance in both new installations and existing system architectures for consistent results.

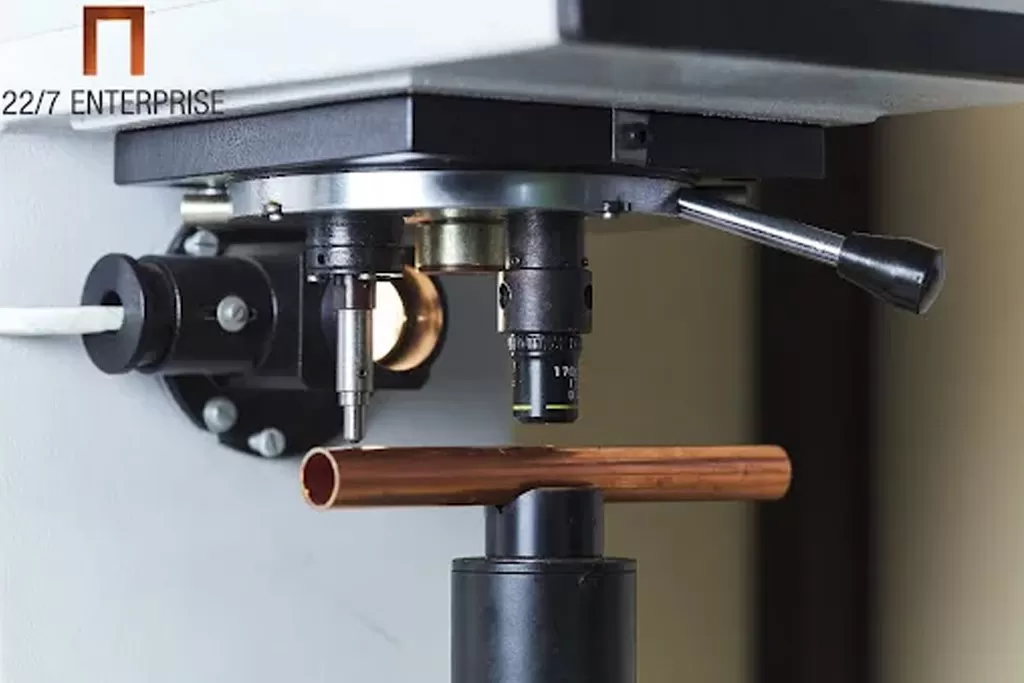

What makes your joints 100% leak-proof?

Our 100% leak-proof guarantee comes from high-precision CNC machining, ensuring perfect seam integrity, followed by a mandatory 6.0 Mpa pressure test on every single unit. This exceeds standard industry tests, providing a dual-process validation that guarantees reliable, leak-free operation for the joint's entire lifetime under all real-world system pressure conditions.

Does the insulation comply with the fire safety of a commercial building?

Yes. Our normal insulation is the self-extinguishing UV-stabilized fire-retardant XPLE, which is of high safety standards. In projects that have more rigid codes, we will provide optional insulation with higher fire ratings. This guarantees maximum adherence to international safety standards in commercial, high-rise and other vital building projects that need certified fire-safe materials.

What is the advantage of the Traceability Marking of your products?

The laser-etched traceability marking provides a unique code for each joint, enabling complete tracking back to its production batch, copper source, and pressure test records. This offers verifiable documentation for warranties, simplifies maintenance audits, and adds a layer of quality accountability that we fully stand behind as the manufacturer.

How do your joints contribute to overall VRF system efficiency?

Precision-bored smooth internal pathways of our joints enhance VRF efficiency, which reduces turbulence and pressure drop. This is to ensure the optimum distribution of refrigerant to all indoor units to enable them to work to their intended capacity. This minimizes the compressor load and the overall energy performance and operational efficiency of the entire system.

What is your lead time for large or custom project orders?

We maintain a strategic inventory of standard configurations for quick dispatch. In large-scale or custom manufacturing, our special manufacturing line provides efficient turnaround. When our sales team reviews the project, you will receive firm, reliable timelines that fit within your construction schedule, which will not delay critical path installation work by having the materials available.

Can you provide customized MI Series assemblies for non-standard layouts?

Yes, customization is one of the main competencies. We design and manufacture custom header systems, special pipe size reducers, and custom joint designs to fit into intricate system designs or older equipment interfaces perfectly. This will guarantee maximum compatibility and performance without any reduction in our high standards of material quality or manufacturing.

What is your pressure testing at 6.0 Mpa in comparison with your competitors?

Our 6.0 Mpa (870 psi) test is 5.2 Mpa higher than our competitors, and it subjects all the components to loads which are much higher than those encountered in normal operation. This high level of validation gives it a higher safety factor, integrity of critical applications and better durability and long term reliability to hard commercial installations.

What are the certifications of your products and manufacturing process?

MI Series products are ROHS, CE and REACH compliant. Our production plant has a certified Quality Management System (QMS) that guarantees a steady production standard. We also offer all the relevant material, certification and compliance documentation needed in professional project submissions and regulatory approvals in the international markets.

What is your post-purchase technical support?

Our after-sales services involve troubleshooting. For large projects, we offer on-site project advice to ensure optimal installation practices. We also assist with product purchase, through to commissioning and handover of the final system.