VRF

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

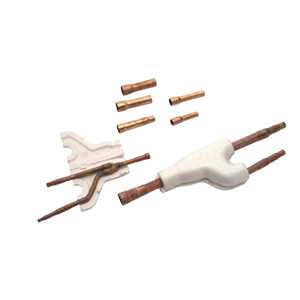

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

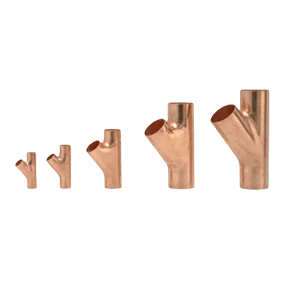

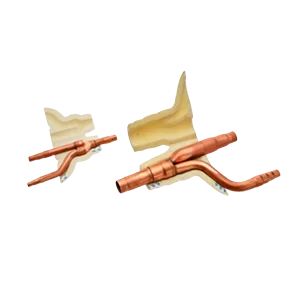

- VRF Y Joint

- VRF Branch Piping

- VRF Refrigerant Branch Piping

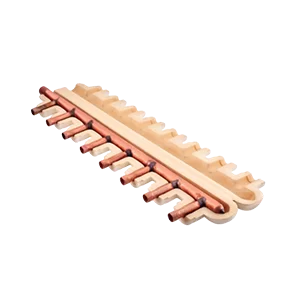

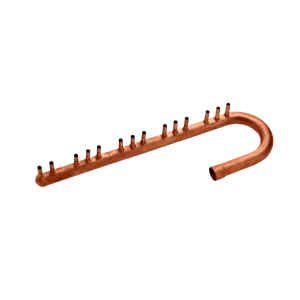

Headers

- SAM Headers

- TA Headers

- Customized Headers

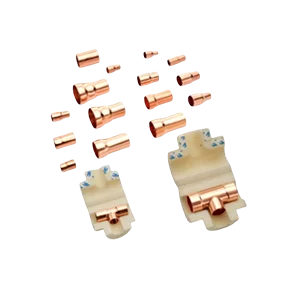

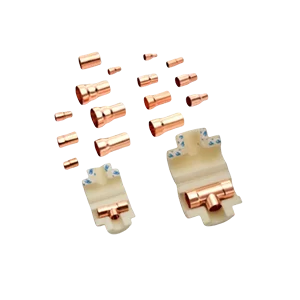

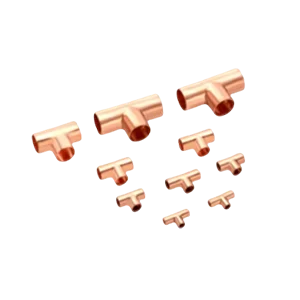

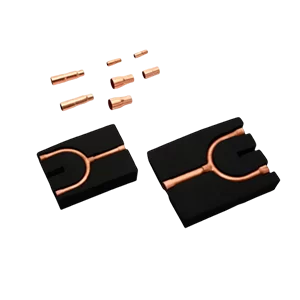

Copper Components

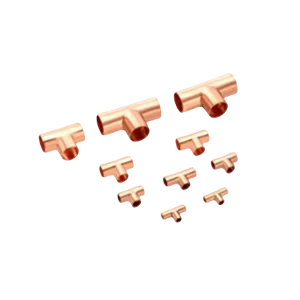

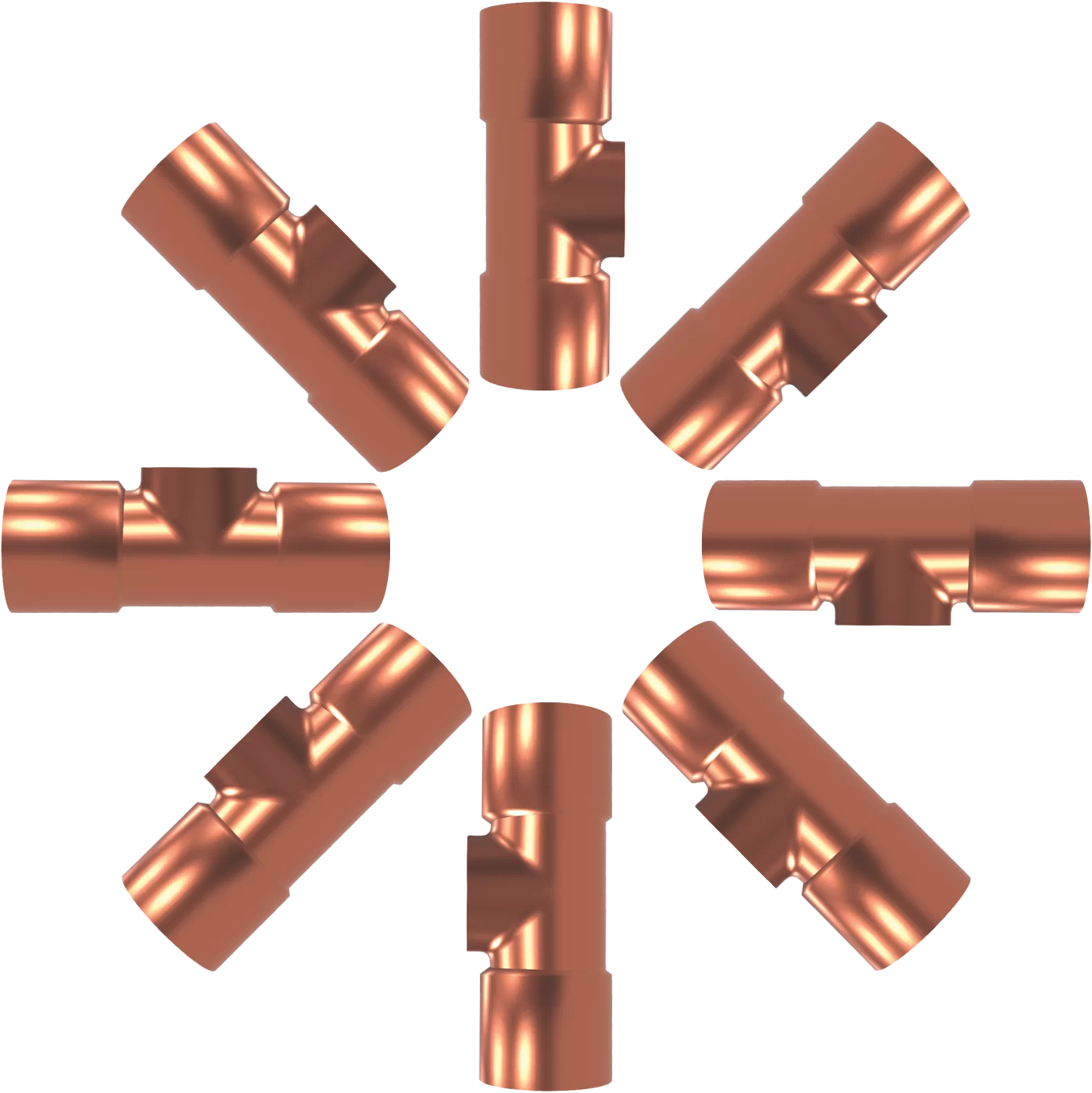

- Copper Compression T Fitting

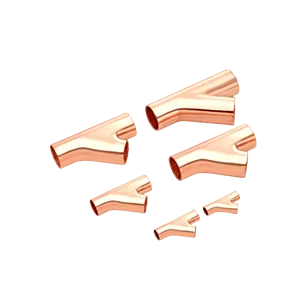

- Copper Y Fitting

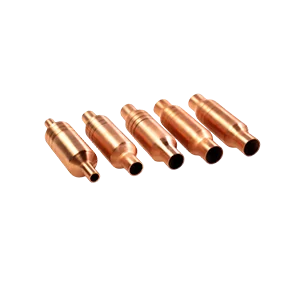

- Strainers

- Mufflers

- Stubs

- Commercial Tee's

- Copper Tee Joint

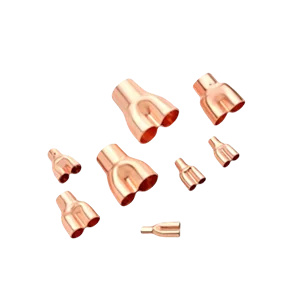

- Y-Type Distributors

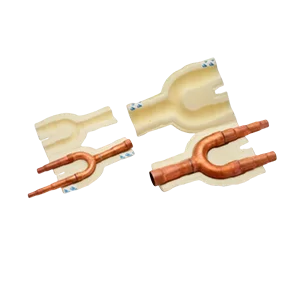

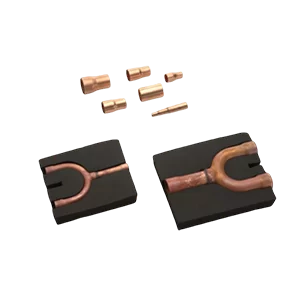

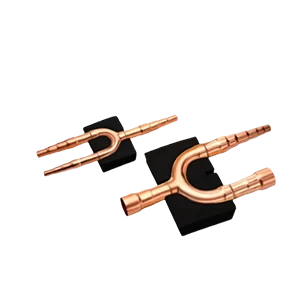

- Unbrazed U & Y Fittings

- Copper Y-Joint

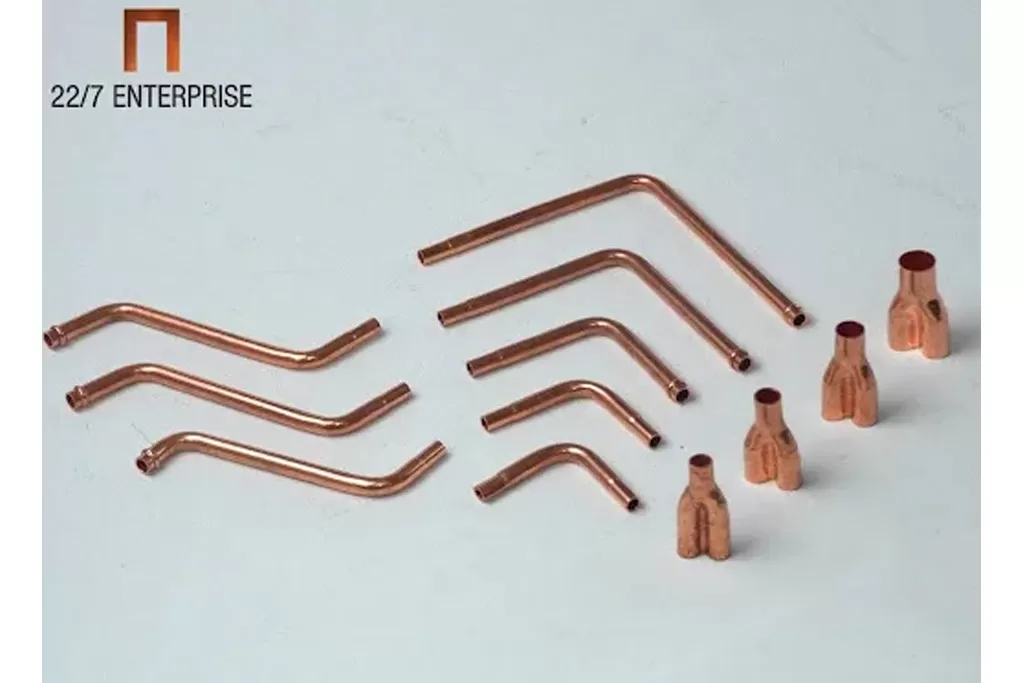

- Tubular Assemblies

Customized insulation

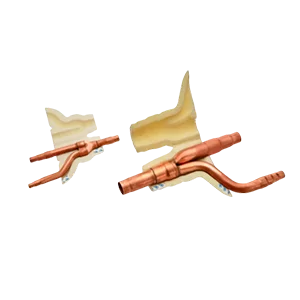

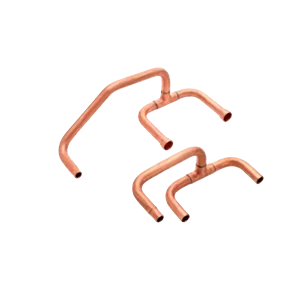

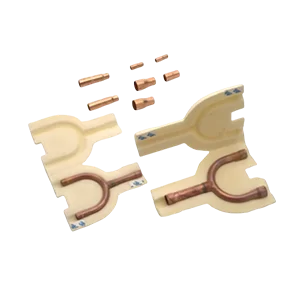

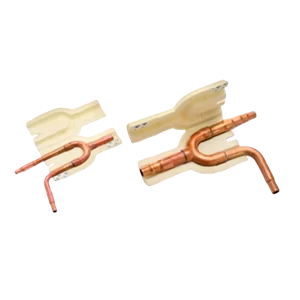

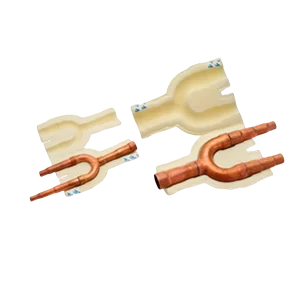

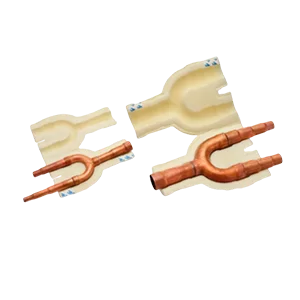

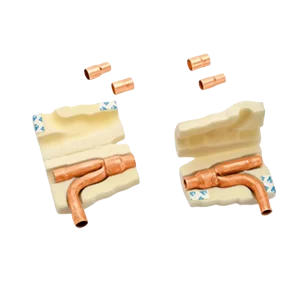

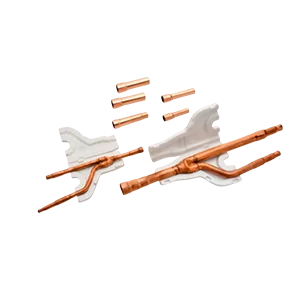

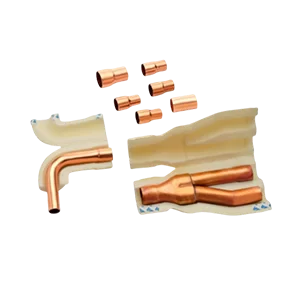

LG Series

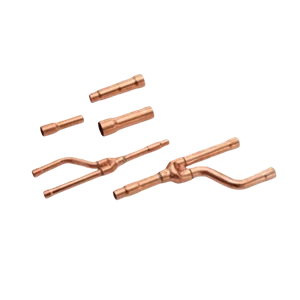

Refrigerant Branch Piping Kit for all types of VRF Systems working on R410 Refrigerant

LG

Series

FEATURES OF LG series

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE compliant

Robust Design

Product specification

| Model No | Pipe A (ID) | Pipe B (ID) | Pipe C (ID) | Reducer |

|---|---|---|---|---|

| Pi-JRBLN01621 (Gas Side) | 15.88 – 12.7 | 12.7 – 15.88 | 12.7 – 15.88 | 19.05 ID X 15.88 OD – 1 Nos |

| Pi-JRBLN01621 (Liquid Side) | 6.35 – 9.52 | 9.52 – 6.35 | 9.52 – 6.35 | 12.7 ID X 9.52 OD – 1 Nos |

| Pi-JRBLN03321 (Gas Side) | 25.4 – 22.22 – 19.05 | 15.88 – 19.05 -12.7 | 15.88 – 19.05 -12.7 | 28.58 ID X 25.04 OD – 1 Nos 22.22 ID X 19.05 OD – 1 Nos 25 ID X 22.22ID X 19.05 OD – 1 Nos |

| Pi-JRBLN03321 (Liquid Side) | 12.7 – 9.52 | 9.52 – 12.7 – 6.35 | 9.52 – 12.7 – 6.35/td> | No Reducer |

| Pi-JRBLN07121 (Gas Side) | 31.8 – 28.58 | 22.22 – 19.05 – 15.88 | 19.05 – 15.88 – 12.7 | 34.9 ID X 31.8 OD – 1 Nos 31.8 ID X 28.58 ID X 22.22 OD – 1 Nos 28.58 ID X 22.22 ID X 19.05 OD – 1 Nos |

| Pi-JRBLN07121 (Liquid Side) | 12.7 – 19.05 – 15.88 | 15.88 – 19.05 – 12.7 | 15.88 – 19.05 – 12.7 | 6.35 ID X 9.52 ID X 12.7 OD – 1 Nos 9.52 ID X 12.7 OD – 1 Nos |

| Pi-JRBLN14521 (Gas Side) | 34.9 – 38.1 – 41.3 | 38.1 – 34.9 – 28.58 | 34.9 – 22.22 | 41.3 ID X 38.1 OD – 1 Nos 41.3 ID X 38.1 ID X 34.9 OD – 1 Nos 15.88 ID X 19.05 ID X 22.22 OD – 1 Nos 12.7 ID X 15.88 OD – 1 Nos 19.05 ID X 22.22 ID X 28.58 OD – 1 Nos |

| Pi-302S-G2 (Liquid Side) | 15.88 – 22.22 – 19.05 | 22.22 – 19.05 -15.88 | 19.05 – 15.88 – 12.7 | 22.22 ID X 19.05 OD – 1 Nos 9.52 ID X 12.7 ID X 15.88 OD – 1 Nos 6.35 ID X 9.52 ID X 12.7 OD – 1 Nos |

| Pi-JRBLN23220 (Gas Side) | 44.48 – 53.98 | 41.28 – 44.48 – 38.1 | 41.28 – 44.48 – 34.93 | 28.58 ID X 31.8 ID X 34.93 ID X 38.1 OD – 2 Nos 53.98 ID X 44.48 OD – 2 Nos 15.88 ID X 19.05 ID X 22.22 OD – 1 Nos 22.22 ID X 25.4 ID X 28.58 OD – 1 Nos 12.7 ID X 15.88 OD – 1 Nos |

| Pi-JRBLN23220 (Liquid Side) | 25.4 – 22.22 | 22.22 – 25.4 – 19.05 | 22.22 – 25.4 – 19.05 | 12.7 ID X 15.88 ID X 19.05 OD – 1 Nos 6.35 ID X 9.52 ID X 12.7 OD – 1 Nos |

OUR Products

Universal

Branch Pipe

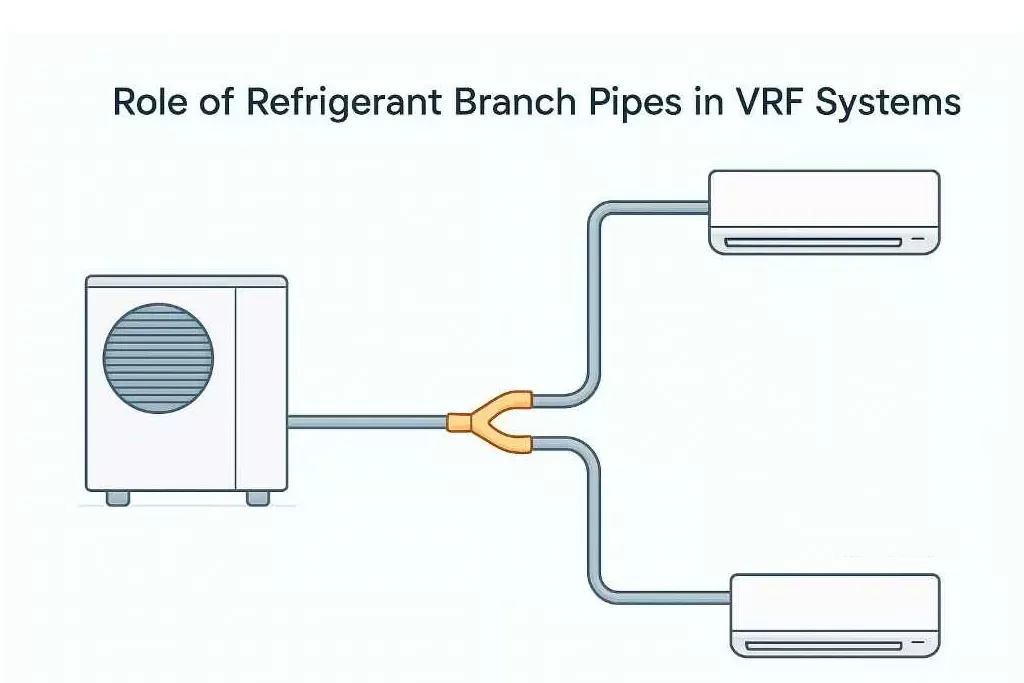

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

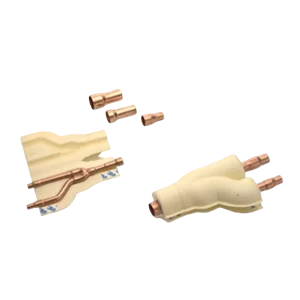

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The leak-proof guarantee and perfect fit of these kits have streamlined all our high-rise VRF projects.

Procurement Head, MEP Consultancy,

Saudi ArabiaUniversal compatibility means we stock one SKU for multiple OEM systems, simplifying our inventory massively.

Project Manager, HVAC Contractor,

UAEThe pressure testing certification provides unmatched confidence in system integrity for our consultancy clients.

Senior Engineer, Building Services Firm,

IndiaDelivery is always on schedule, which is critical for keeping our tight construction timelines.

Site Supervisor, Construction Company,

QatarThe quality is consistently OEM-grade, making 227 Enterprise our trusted partner for critical components.

Technical Director, VRF OEM,

EuropeOur Blogs

FAq's

What is the LG Series Branch Pipe?

It is a prepared refrigerant pipe system kit of VRF. It has copper Y-joints and reducers that divide the flow directly in the middle of the inside units to make zoning efficient and reduce the amount of spot-on-site assembly and brazing.

Does it work with any VRF brands?

Yep! Its multi-step design is compatible with virtually any major brand of VRF. That is one of the solutions to a collection of projects.

What is the pressure rating of these joints?

All pieces are stamped out using 5.2mpa pressure test. That is more than normal, and thus you will be assured of a leak-free seal and a long-lasting stability even in harsh conditions.

Which insulation types can be used?

Choose between UV stabilized Fire Grade XLPE or flexible NBR. They are both laser-cut to fit snugly to prevent sweating and maintain the thermal performance of the lineup, in addition to being resistant to moisture throughout life.

Are the associations leak-proof?

Totally. Each component undergoes a 5.2 MPA pressure test, which is fabricated with accuracy of copper and ingenious design. This holds the system in place, the refrigerant contained, and the environment intact.

How long does it normally take to deliver?

They have ready stock to be immediately dispatched. Normal orders take 3-5 business days to reach any part of India, or you can use express shipping in case you are in a hurry.

Is it possible to demand a personalized kit?

Definitely. 227 Enterprise is a company of custom solutions. Ask them your layout as it is, the size of pipes, and what you want to be connected to, and they will charge you a custom quote.

Are they certified products?

Yes. All LG Series parts are of ROHS and CE standards, which shows that they are safe, healthy, and eco-friendly to use all over the world.

What does this kit do to decrease installation time?

Since it is all ready-made and uses specific components. It eliminates site measuring, site cutting and brazing, shaving up to 60 percent and eliminates cutting labor and errors and speeds up roll out.

What guarantee or maintenance do you give?

They support it with a good warranty on defects as well as good product support. The technology team is available to assist with installation and troubleshooting, thus being able to complete projects with ease and without worrying.