Headers

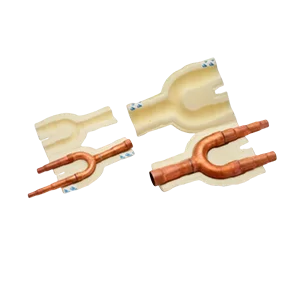

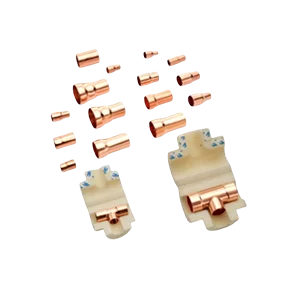

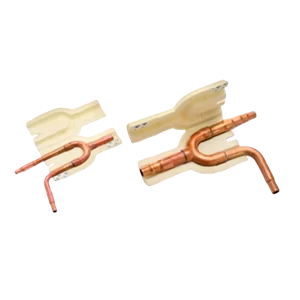

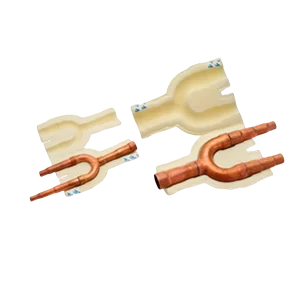

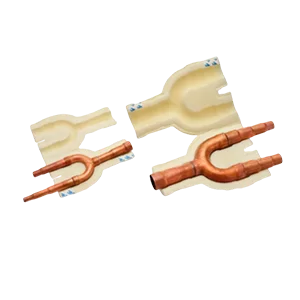

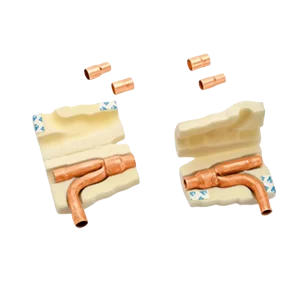

Customized insulation

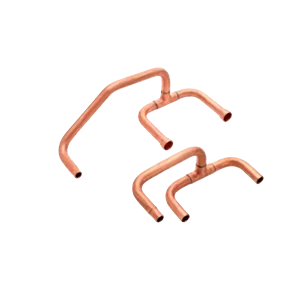

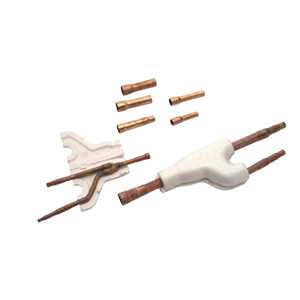

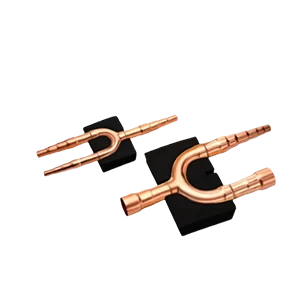

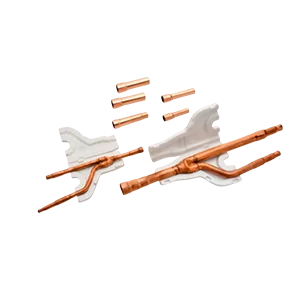

HAE Series

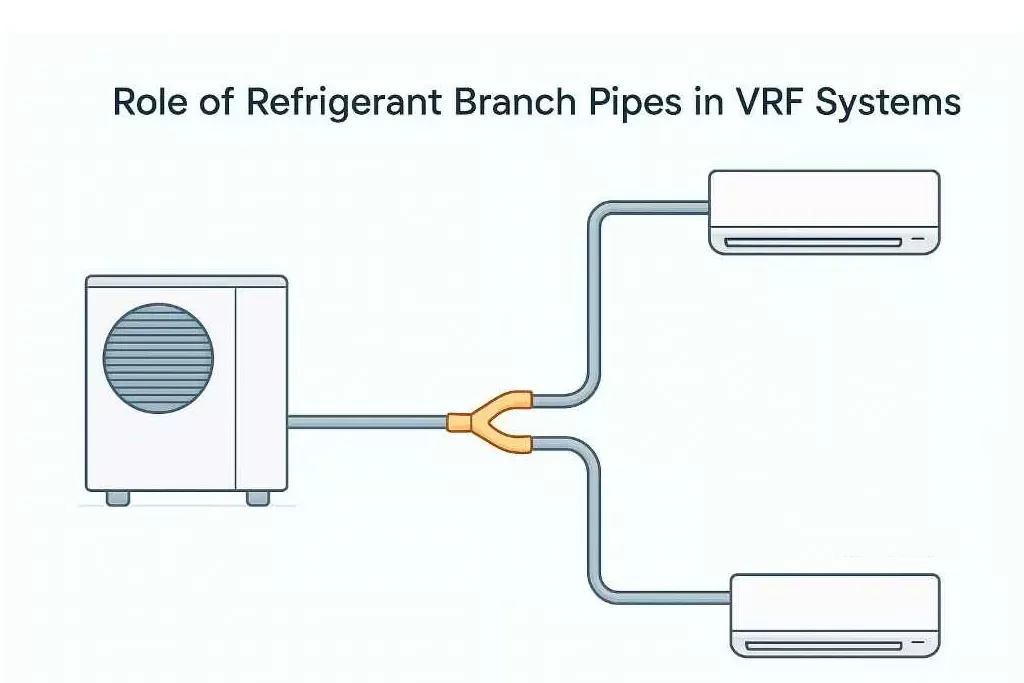

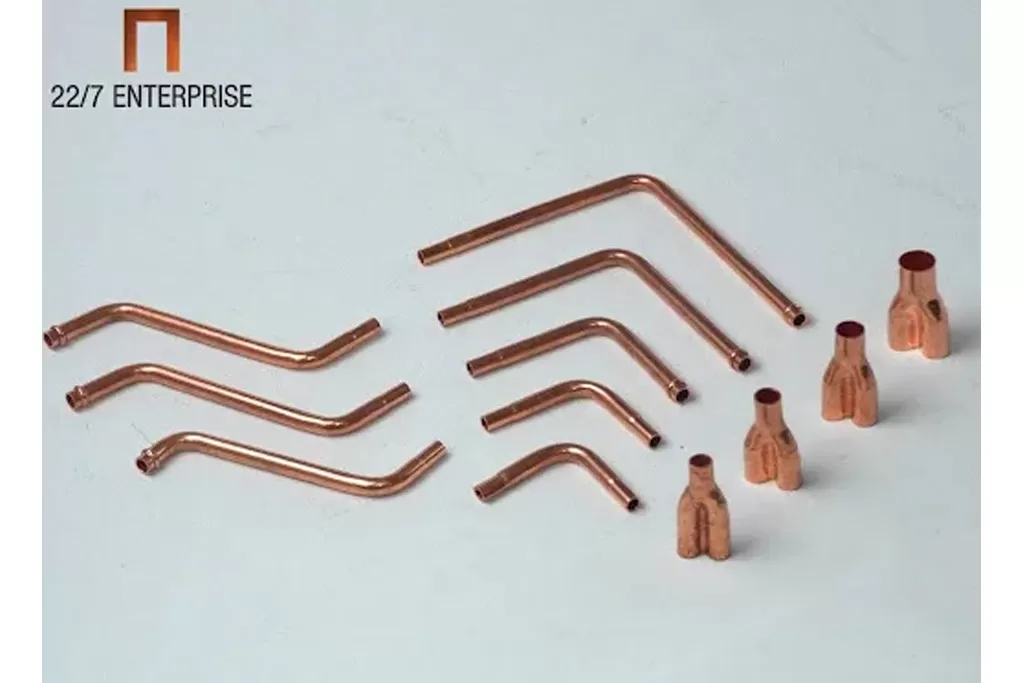

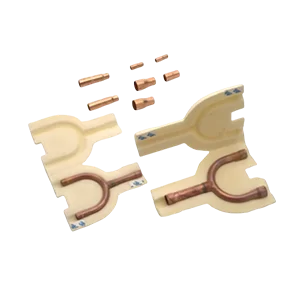

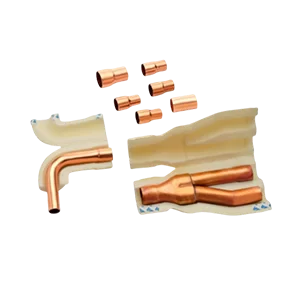

Refrigerant Branch Piping Kit for all types of VRF Systems working on R410 Refrigerant

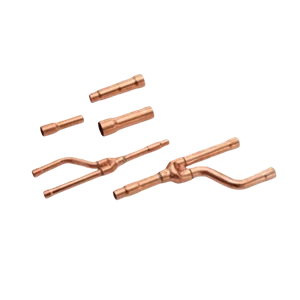

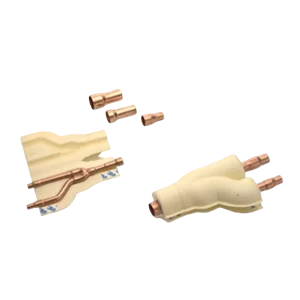

The HAE Series VRF Refrigerant Branch Piping Kit is a high-precision Y-branch which ensures that the refrigerant flows evenly to the indoor units. It is constructed of high-grade copper and is multi-step designed, thus making it easy to connect the various pipe sizes, thus reducing the time of installation and reducing the risk of leaks.

HAE

Series

FEATURES OF HAE series

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE Compliant

Robust Design

Product specification

| Model Number | Pipe | Pipe A (ID) | Pipe B (ID) | Pipe C (ID) | Reducers Number & Qty |

|---|---|---|---|---|---|

| Pi-18M7 | Gas Side | 28.58 (1-1/8) – 25.4 (1) | 22.2 (7/8) – 25.4 (1) – 28.58 (1-1/8) | 22.2 (7/8) – 19.05 (3/4) – 15.88 (5/8) | 3 X 1 Nos, 1 X 1 Nos |

| Liquid Side | 12.7 (1/2) | 12.7 (1/2) – 9.52 (3/8) | 15.88 (5/8) – 12.7 (1/2) | 2 X 1 Nos | |

| Pi-26M7 | Gas Side | 28.58 (1-1/8) – 25.4 (1) | 22.2 (7/8) – 25.4 (1) – 28.58 (1-1/8) | 22.2 (7/8) – 19.05 (3/4) – 15.88 (5/8) | 3 X 1 Nos, 1 X 1 Nos |

| Liquid Side | 15.88 (5/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) | 2 X 1 Nos | |

| Pi-48M7 | Gas Side | 38.1 (1-1/2) – 31.75 (1-1/4) | 31.75 (1-1/4) – 38.1 (1-1/2) | 28.58 (1-1/8) | 3 X 1 Nos, 4 X 1 Nos, 5 X 1 Nos |

| Liquid Side | 19.05 (3/4) – 22.2 (7/8) | 22.2 (7/8) – 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) | 2 X 1 Nos | |

| Pi-72M7 | Gas Side | 50 (2).8 – 44.4 (1-5/8) – 41.28 (1-5/8) | 41.28 (1-5/8) – 44.4 (1-5/8) – 41.28 (1-5/8) – 38.10 (1-1/2) – 31.75 (1-1/4) | 38.10 (1-1/2) – 31.75 (1-1/4) – 28.58 (1-1/8) – 25.4 (1) | 6 X 1 Nos, 7 X 1 Nos |

| Liquid Side | 22.2 (7/8)2 – 25.4 (1) | 22.2 (7/8) – 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 22.2 (7/8) – 19.05 (3/4) – 15.88 (5/8) | 1 X 1 Nos |

Reducer no. & size

| 1 | 9.52 (3/8) ID X 12.7 (1/2) OD |

| 2 | 9.52 (3/8) ID X 6.35 (1/4) OD |

| 3 | 28.58 (1-1/8) OD X 25.4 (1) ID X 22.7 (7/8) ID X 19.05 (3/4) ID X 15.88 (5/8) ID X 12.7 (1/2) ID |

| 4 | 31.75 (1-1/4) OD X 28.58 (1-1/8) ID X 25.4 (1) ID X 22.2 (7/8) ID |

| 5 | 38.1 (1-1/2) OD X 34.93 (1-3/8) ID |

| 6 | 25.4 (1) ID X 22.2 (7/8) ID X 19.05 (3/4) ID X 15.88 (5/8) OD |

| 7 | 50 (2) ID X 44.4 (1-5/8) OD |

OUR Products

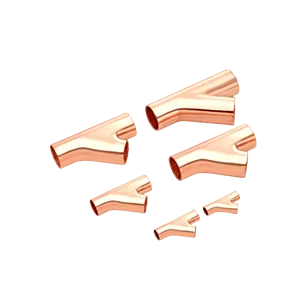

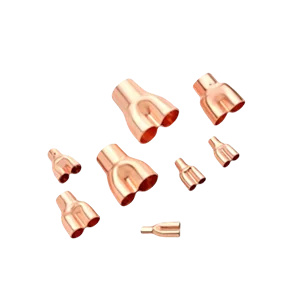

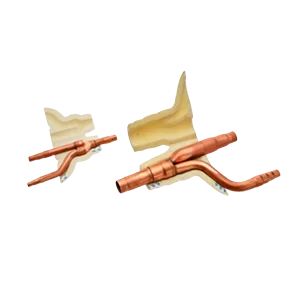

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

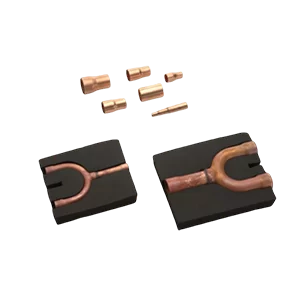

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

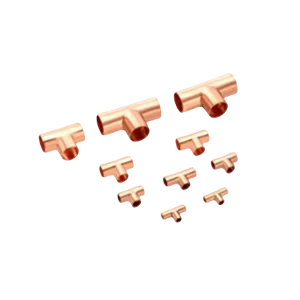

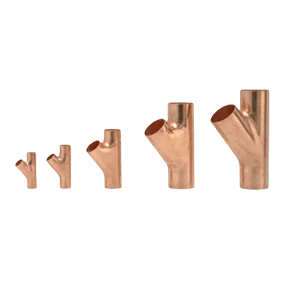

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

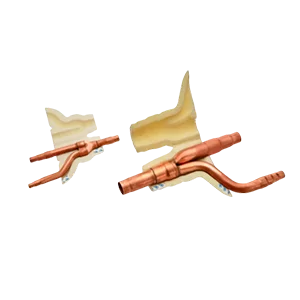

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

AX

Series

Engineered for high-performance R410a and next-generation-ready VRFXR ecosystems

View Details

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

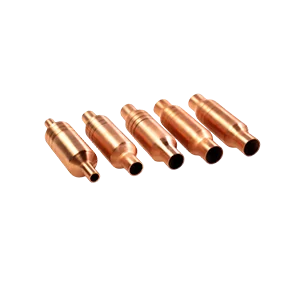

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

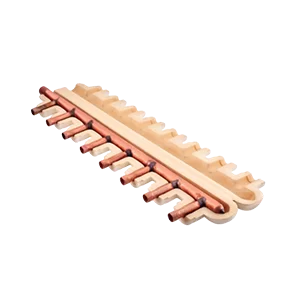

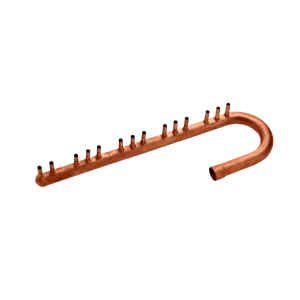

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

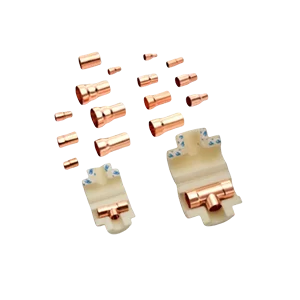

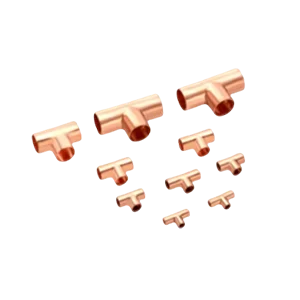

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

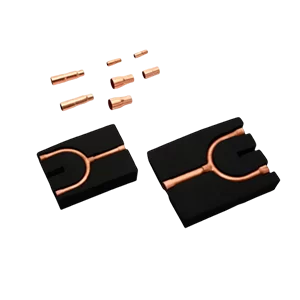

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The HAE Series kit cut our installation time by 30% and eliminated callbacks for leaks.

Procurement Head, MEP Consultancy,

Saudi ArabiaWe’ve standardized on 227 Enterprise for all our VRF projects because of their consistent quality and reliable supply.

Project Manager, HVAC Contractor,

UAEThe laser‑cut insulation fits perfectly, reducing on‑site labor and ensuring a professional finish.

Service Engineer, Facility Management Company,

QatarTheir pressure‑testing certification gives us confidence in system longevity, crucial for high‑rise buildings.

Design Engineer, Consulting Firm,

IndiaCustomizable insulation options and responsive technical support make 227 our preferred supplier.

Owner, HVAC Distributor,

OmanOur Blogs

FAq's

What is the HAE Series VRF Refrigerant Branch Piping Kit?

The HAE Series is a pre-insulated, precision-engineered Y-branch system manufactured using ASTM B280 copper, which divides R410 refrigerant of one of the outdoor units to several indoor VRF units to maintain a balance in flow, pressure drop, and the connection 100% leak-free to ensure maximum efficiency of the system and long-term performance.

Does the HAE Series support any VRF brand?

Yes, it is compatible with all the leading VRF/VRV brands, which uses R410A. Its multi-step joint accommodates standard pipe sizes; therefore, it is a multi-purpose and single-source solution to any project.

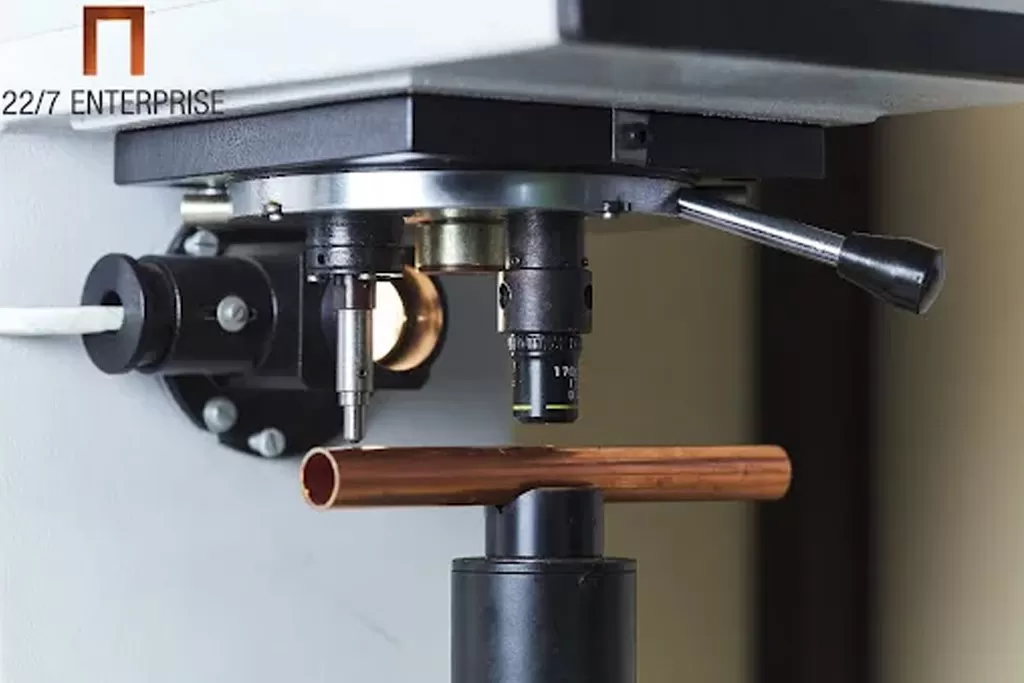

What is the pressure that the branch pipe is tested to?

Each HAE Series joint is put through a hydrostatic test at our factory, using water at 5.2 MPa. It’s a straightforward way for us to check that the joint is properly sealed and structurally sound, so when it’s installed and running under normal conditions, leakage isn’t something you have to worry about.

How does the kit provide leak-proof performance?

It brazes with high-silver-content in nitrogen purge to prevent internal oxidation. Then every connection is tested with hydrostatic and vacuum decay tests, which ensures an ideal airtightness. That multi-step quality inspection ensures that refrigerant does not leak throughout the installation.

What are the options for insulation?

We have two high-quality, laser-cut choices: regular NBR (Nitrile Rubber) that provides excellent thermal and moisture protection, and fire-resistant XLPE (Cross-Linked Polyethene) to provide additional fire protection in vulnerable areas. They are both fit perfectly, block condensation, resistant to UV and corrosion.

Is the HAE Series adaptable to project requirements?

Yes, 227 Enterprise is fond of custom work. We can adjust the lengths of pipes, types of insulation used, as well as their thickness, and connector configurations to the layout you need. It is also possible to add your own branding and traceability labels to your project ID and quality documentation.

What are the certifications of the HAE Series?

We produce our unit in an ISO 9001: 2015 certified facility, and we are perfectly RoHS and CE-compliant. The copper is compliant with ASTM B280, and XLPE insulation is fire grade and therefore has the correct fire safety certification, hence we comply with global safety, quality and environmental standards.

What is the advantage of the HAE Series in terms of VRF system efficiency?

Its internal flow divides refrigerant turbulence and pressure drop, allowing the compressor to work less. This accurate flow enhances heat exchange in all the indoor units,s whicsavesve on energy and minimizes the wear of the system in the long run.

How long is the lead time for orders?

Normal kits are shipped within 3-5 working days. In case of custom orders, lead times are dependent on the complexity of the spec. Our sales crew will provide you with a hard schedule once you have placed the order, and your install will not be left behind.

Does the kit include a warranty?

Yes. 227 Enterprise Pvt. Ltd. covers manufacturing defects in materials or workmanship under warranty. Moreover, our kits deliver reliable performance, durable build quality, and dependable operation, giving customers confidence in their purchase