Headers

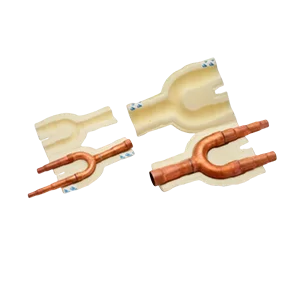

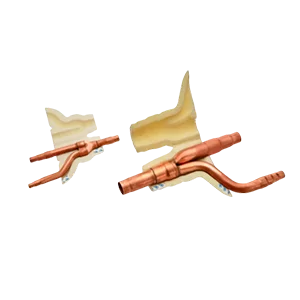

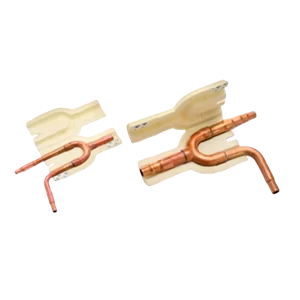

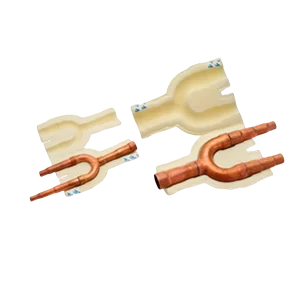

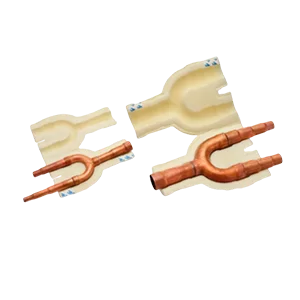

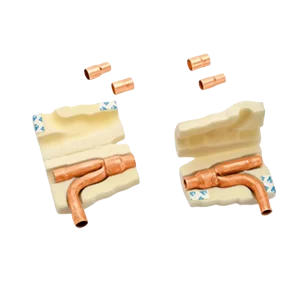

Customized insulation

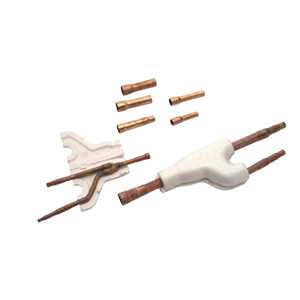

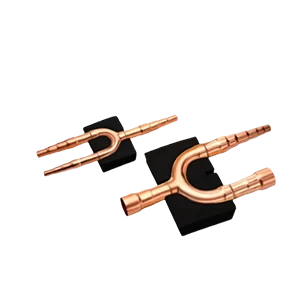

GR Series

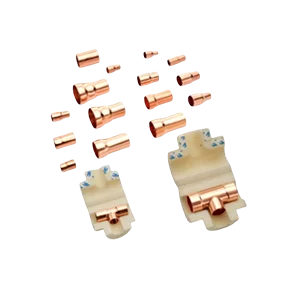

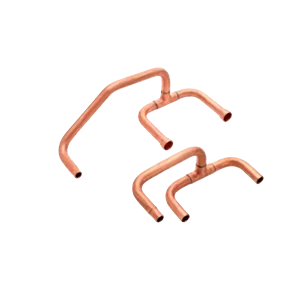

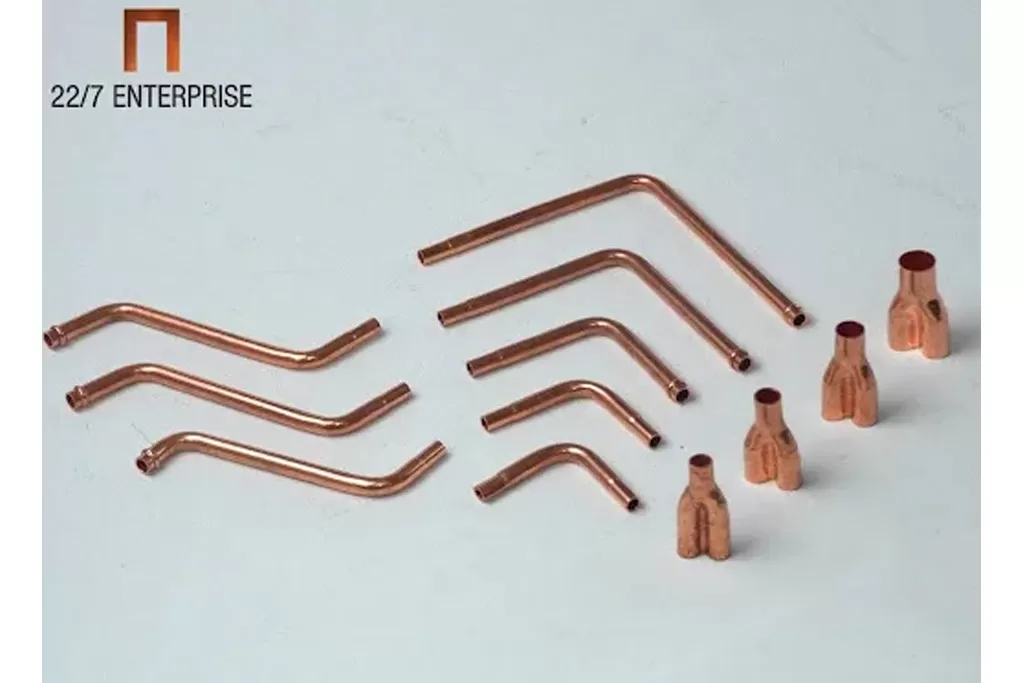

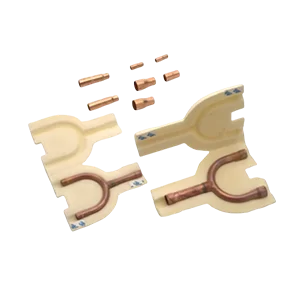

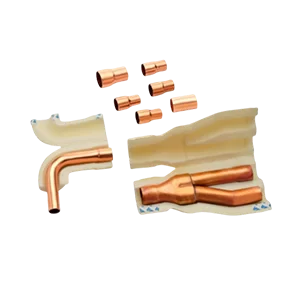

Refrigerant Branch Piping Kit for all types of VRF Systems operating on R410A Refrigerant

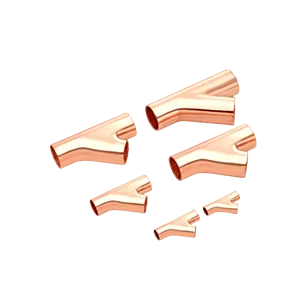

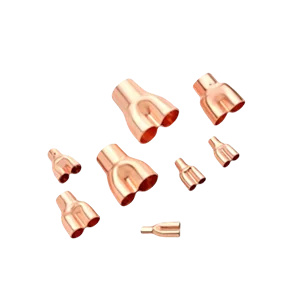

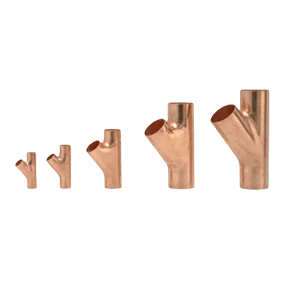

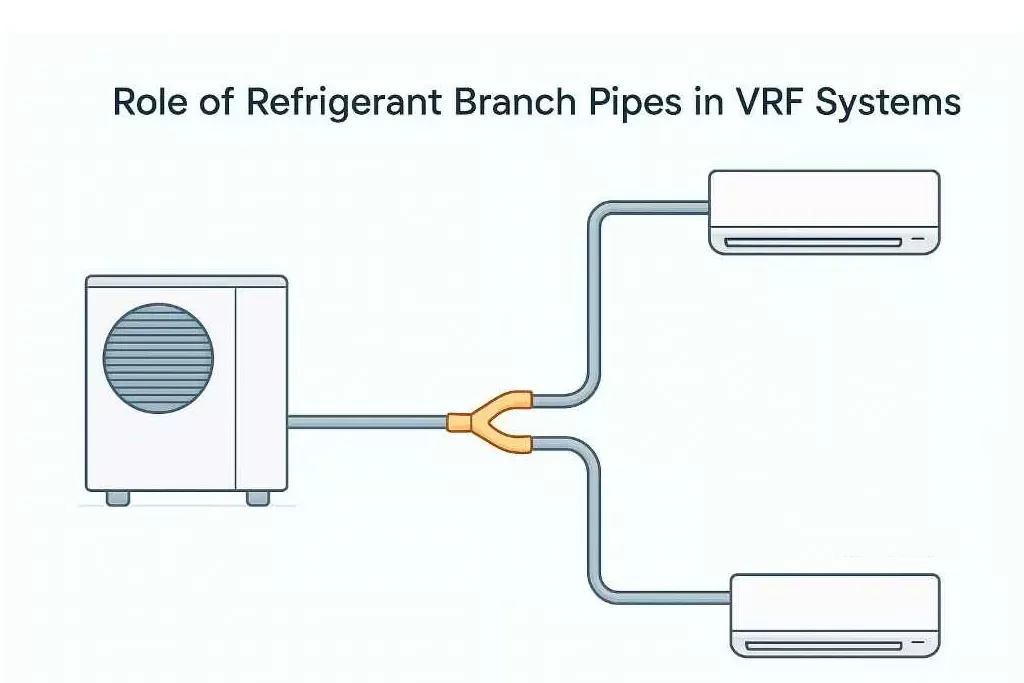

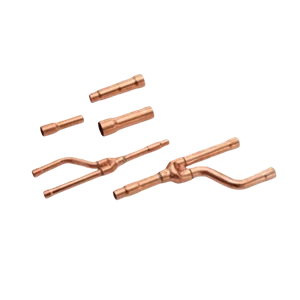

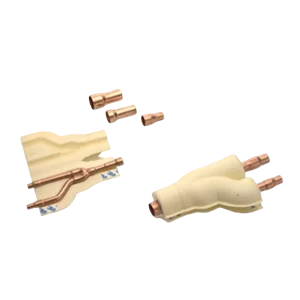

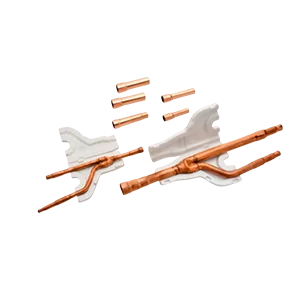

GR Series VRF Y Joints play a vital role in VRF systems by guiding refrigerant evenly between outdoor and indoor units. Built for demanding cooling and heating applications, they keep operation stable, improve energy performance, and maintain uniform comfort across all connected zones in the installation.

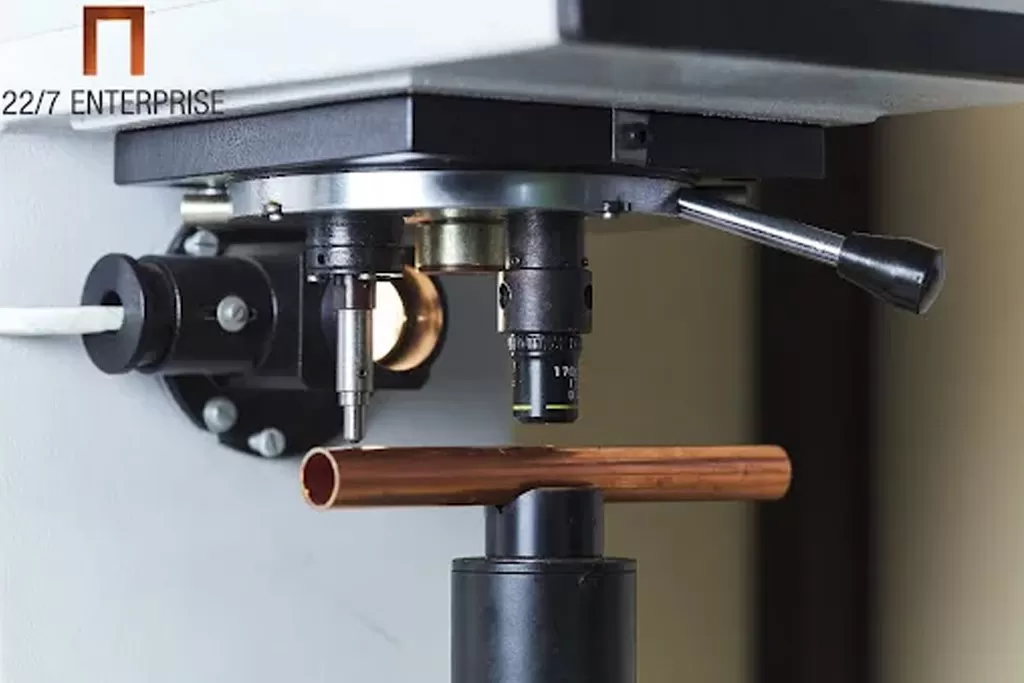

GR Series VRF Y Branch Pipes use in-house copper Y joints brazed with 2% silver for dependable leak-free service. Chamfered ends ensure accurate alignment, while compatible reducers ease installation. Each unit includes XLPE or NBR insulation. Manufactured by 227 Enterprise Pvt. Ltd. for consistent VRF performance.

GR

Series

FEATURES OF GR series

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE compliant

Robust industrial-grade design

Product specification

| Model | Pipe | Pipe A (ID) | Pipe B (ID) | Pipe C (ID) |

|---|---|---|---|---|

| Pi-FQ01A/A | Gas Side | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) | 15.88 (5/8) – 12.7 (1/2) |

| Liquid Side | 9.52 (3/8) | 9.52 (3/8) – 6.35 (1/4) | 9.52 (3/8) – 6.35 (1/4) | |

| Pi-FQ01B/A | Gas Side | 19.05 (3/4) – 22.22 (7/8) | 19.05 (3/4) – 15.88 (5/8) | 15.88 (5/8) – 12.7 (1/2) |

| Liquid Side | 9.52 (3/8) – 12.7 (1/2) | 9.52 (3/8) – 6.35 (1/4) | 9.52 (3/8) – 6.35 (1/4) | |

| Pi-FQ02A | Gas Side | 22.22 (7/8) – 25.4 (1) – 28.58 (1-1/8) | 28.58 (1-1/8) – 25.4 (1) – 22.2 (7/8) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) |

| Liquid Side | 9.52 (3/8) – 12.7 (1/2) – 15.88 (5/8) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) | |

| Pi-FQ03A | Gas Side | 34.93 (1-3/8) – 38.10 (1-1/2) | 41.28 (1-5/8) – 34.93 (1-3/8) – 28.58 (1-1/8) | 28.58 (1-1/8) – 25.4 (1) – 22.22 (7/8) – 19.05 (3/4) |

| Liquid Side | 15.88 (5/8) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) | |

| Pi-FQ04A | Gas Side | 41.7 (1-5/8) – 54.3 (2) – 44.7 (1-3/4) | 54.3 (2) – 41.7 (1-5/8) – 34.93 (1-3/8) | 34.93 (1-3/8) – 28.58 (1-1/8) – 25.4 (1) |

| Liquid Side | 19.05 (3/4) – 22.22 (7/8) | 22.22 (7/8) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) |

OUR Products

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

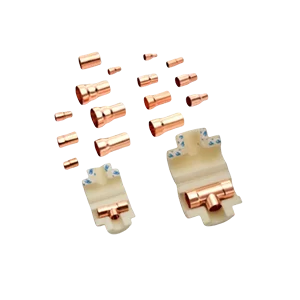

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

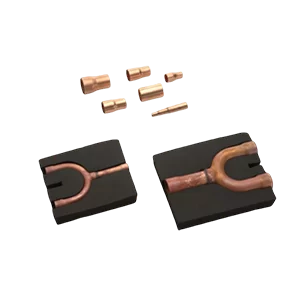

ME

Series

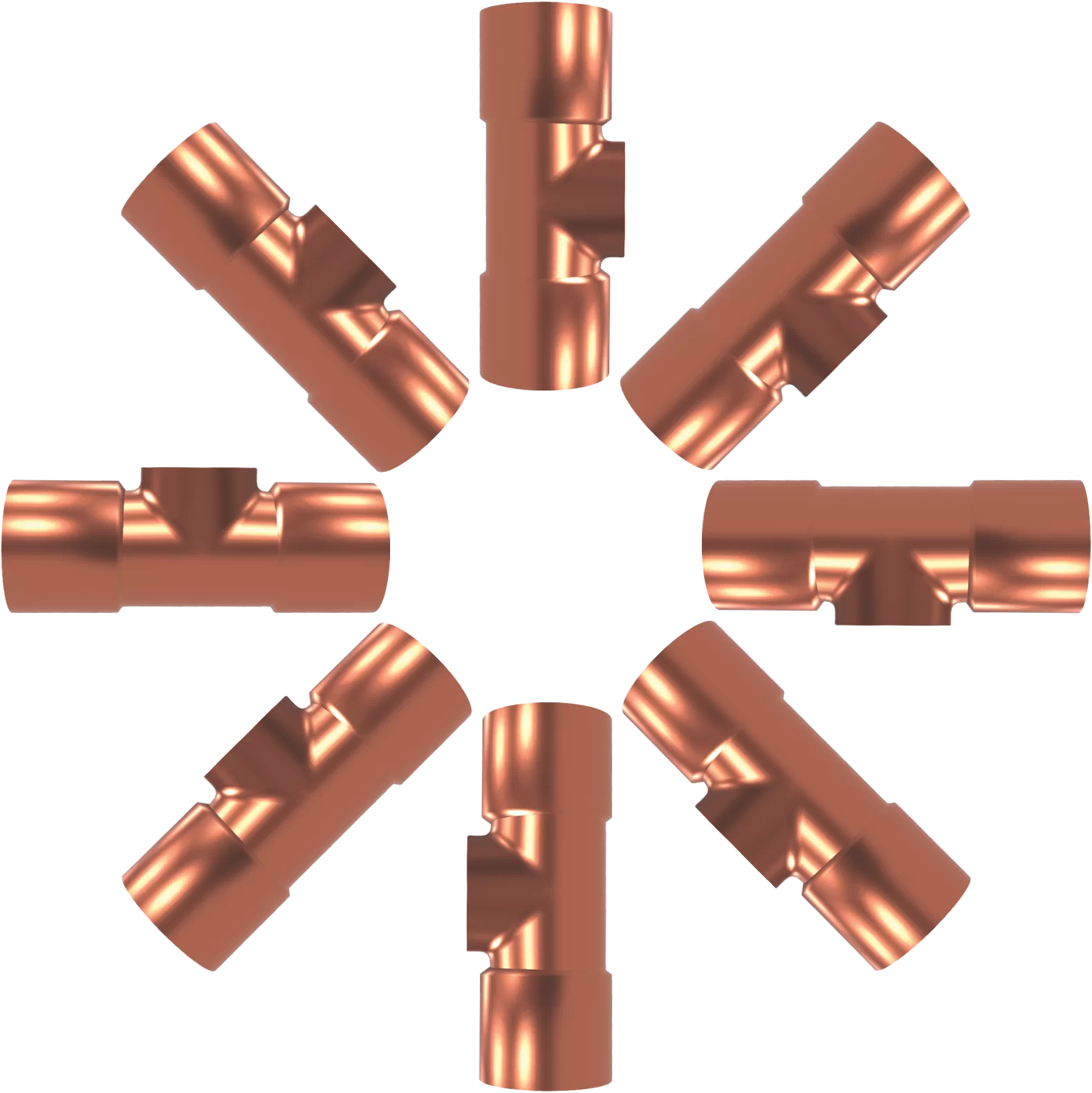

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

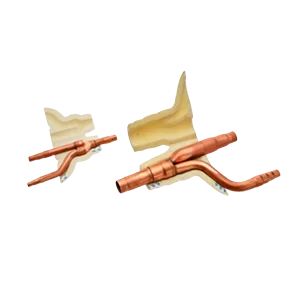

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

AX

Series

Engineered for high-performance R410a and next-generation-ready VRFXR ecosystems

View Details

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

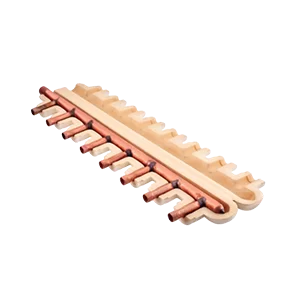

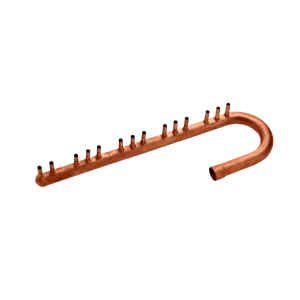

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

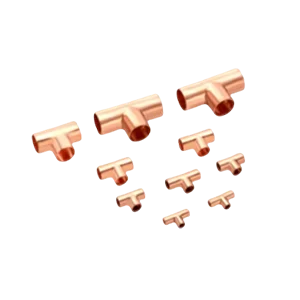

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

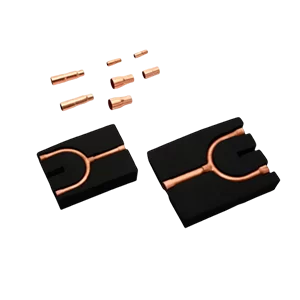

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The way 227 Enterprise tracks it all and guarantees that there is no leakage whatsoever is a reason why we did not need to spend time testing it on site, and we have confidence in the system.

Head of Procurement, MEP Consultancy,

Saudi ArabiaTheir GR Series is compatible with any brand, thus managing the project was very easy, and the technological support was big time phenomenal.

Luxury Hospitality developer, project director,

UAEWe have been working with 227 Enterprise in all our VRF projects since the parts are always presentable, and the insulation prevents any sweating.

Mechanical Contractor,

Japan, Senior Engineer.They have perfect Y-joints which are machined and rounded edges, hence very fast to install, which reduces a lot of labor expenses.

HVAC Specialist Firm,

Singapore, Installation Supervisor.The bespoke kit they produced of our fancy retrofit came on time and fitted as well as any glove, which demonstrates that they know how to engineer.

MEP Manager, Large-scale Commercial Contractor,

Qatar.Our Blogs

FAq's

Why are the GR Series any different from regular copper Y-joints?

They are not mere loose components; these are ready-assembled, ready-insulated, 2 percent silver-brazed joint, kits. All kits receive a leak test in the factory, and thus, the installation is fast and the VRF system performs optimally. It eliminates the guesswork of field brazing and provides you with solid, dependable performance that is difficult to match using ordinary kits.

Do GR Series kits work with all major VRF/VRF brands?

Yep. It is designed to fit all the major contenders that use R410A. It translates into fewer headaches in the process of purchasing a project that requires a combination of brands, since you will not be required to go on a hunt in search of brand-specific components. The GR kit will fit in perfectly.

What do you do to make the joints 100 per cent leak-proof?

Every joint is brazed with a 2% silver alloy to create a strong, lasting bond. After brazing, each one is pressure-tested at 5.2 MPa to make sure the seal is completely tight. This two-step check gives us the confidence that the joint will stay secure and perform consistently, even through the high-pressure cycles typical of R410A systems.

What are the certifications of your GR Series products?

The kits are safe and environmentally friendly as they comply with the ROHS and CE standards. We have our own internal quality assurance and can provide you with complete material certifications and test reports whenever you require them for your project files, audit or QA reviews.

Are you able to offer custom-configured kits to non-standard projects?

Absolutely. We know how to customize branch piping kits to fit special layouts, odd port configurations or additional insulation requirements. Only send us your specs, and we will make you a perfect-fit kit, with no compromise in quality or leaks.

How long are the lead times on orders?

GR kits of standard are available in stock and can be shipped quickly. In the case of custom builds, we provide a definite production schedule when you place the order. We deliver on time to ensure that your project is on schedule.

What are the insulation alternatives?

Our insulation is of the highest grade UV-stabilized XPLE or Armaflex Class O NBR. That material prevents the loss of energy, prevents any form of sweating or condensation, and keeps the interior of the building dry and free of mould. It is also fire-rated, and hence it assists in safety compliance of commercial and residential installations.

Do you offer technical installation services?

For sure. Our HVAC professionals will distribute user-friendly manuals and discuss with you the most suitable piping designs. They are even willing to assist you in installing the GR kit in a manner that the entire VRF system will be running smoothly and reliably.

What is the benefit of this to the VRF system efficiency?

The kits ensure that refrigerant flows uniformly with little pressure drop and turbulence. That allows each of the indoor units to receive the precise flow they require, maintaining the entire system at the highest level of SEER/COP performance and reducing the energy consumption and operating expenses.

What is your after-sales policy?

We support it with a good warranty and powerful after-sales service. Our monitoring system identifies any problems in a short period of time, and our team is on top of it to ensure that your system is performing excellently over the long term.