VRF

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

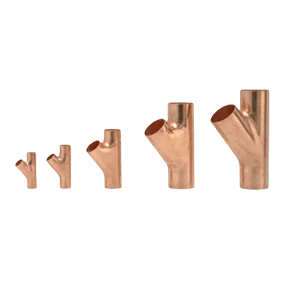

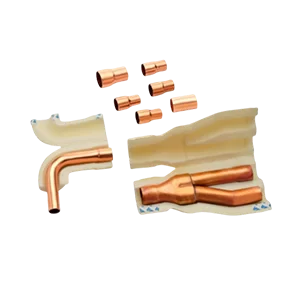

- VRF Y Joint

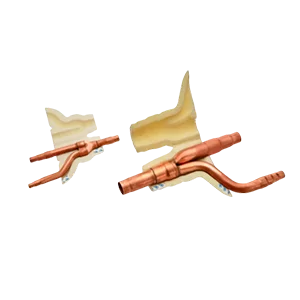

- VRF Branch Piping

- VRF Refrigerant Branch Piping

Headers

- SAM Headers

- TA Headers

- Customized Headers

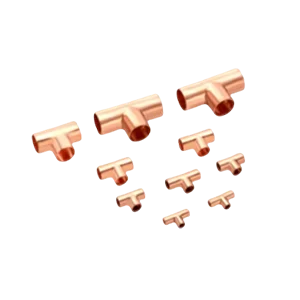

Copper Components

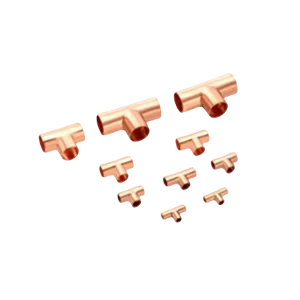

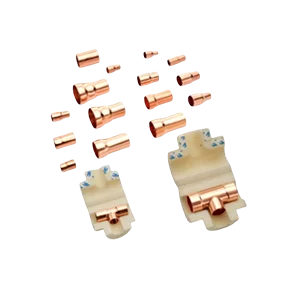

- Copper Compression T Fitting

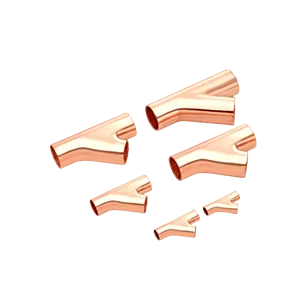

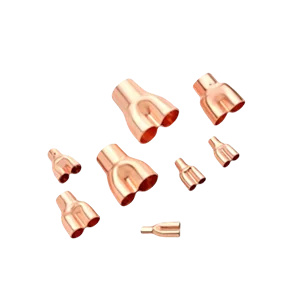

- Copper Y Fitting

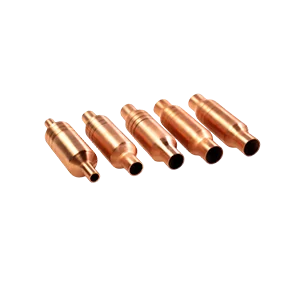

- Strainers

- Mufflers

- Stubs

- Commercial Tee's

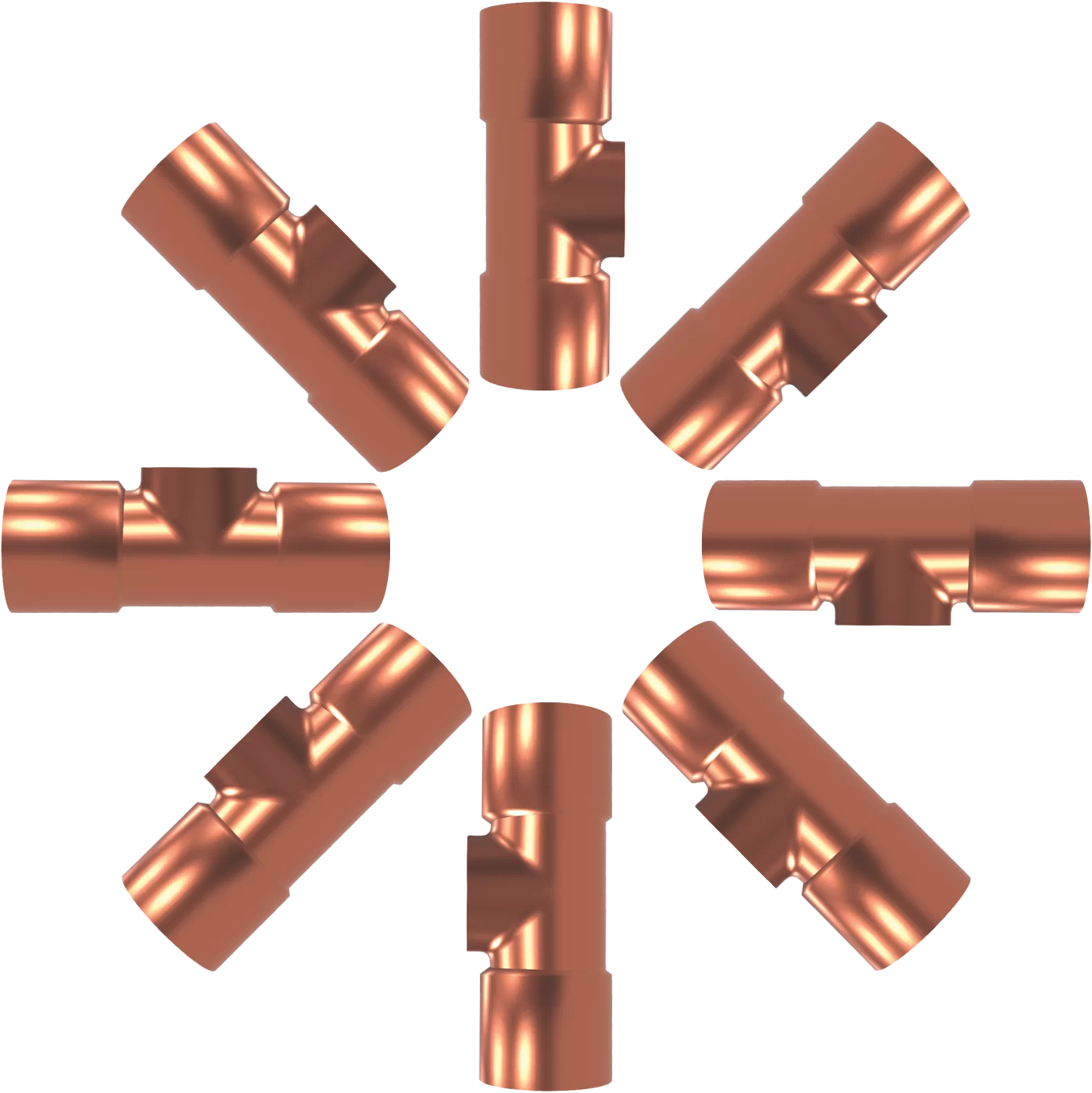

- Copper Tee Joint

- Y-Type Distributors

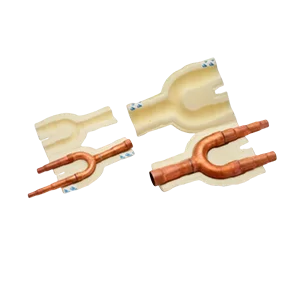

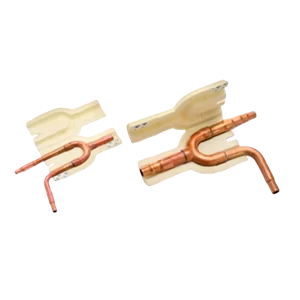

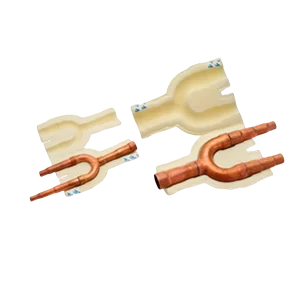

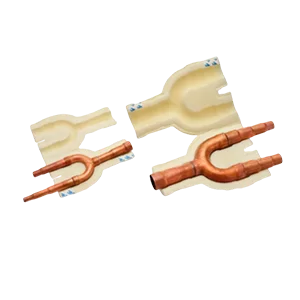

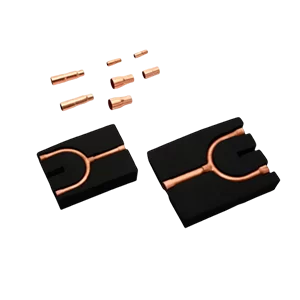

- Unbrazed U & Y Fittings

- Copper Y-Joint

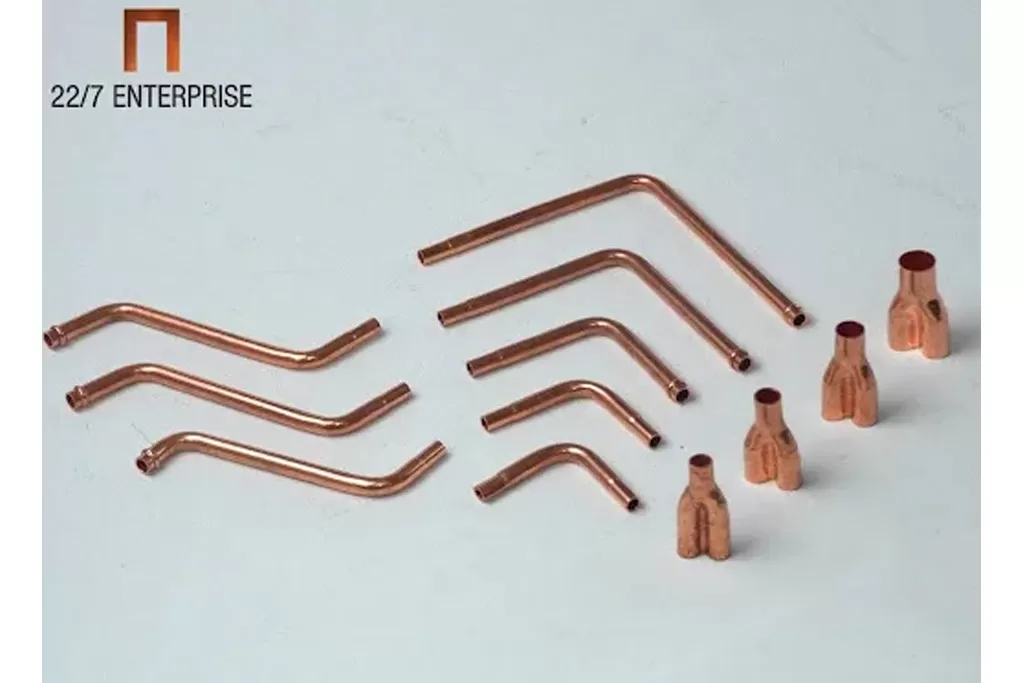

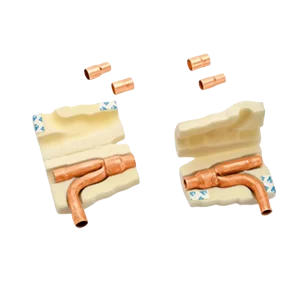

- Tubular Assemblies

Customized insulation

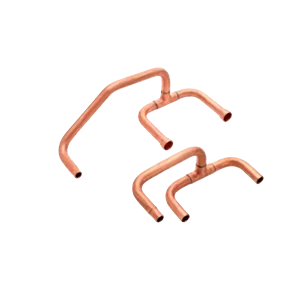

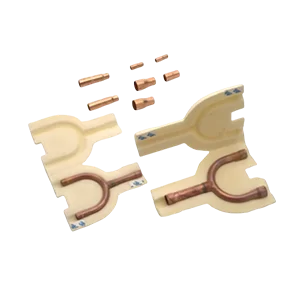

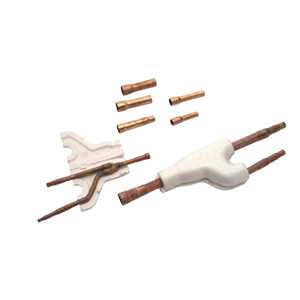

Copper Y Fittings

Customized Copper Y Fittings for every type of HVAC&R System. Engineered for reliability, built for efficiency

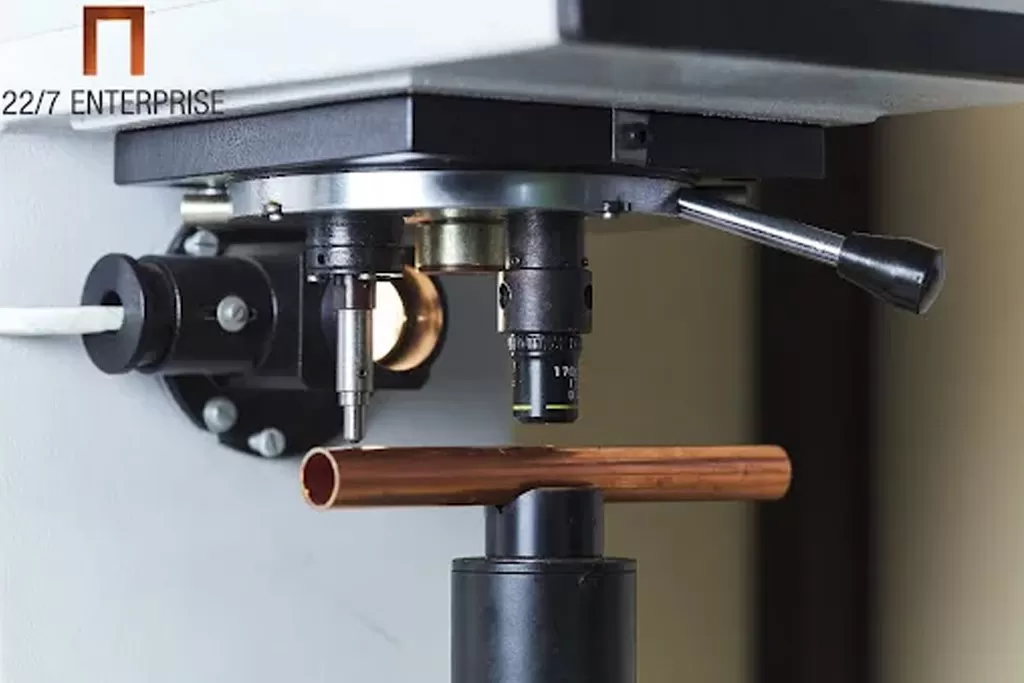

Copper Y joints play a vital role across commercial & industrial HVAC systems, thanks to their adaptable geometry and flow efficiency. 227 Enterprise supplies both equal & reducing configurations, manufactured with tight dimensional accuracy, long service life, and reliable joint integrity for smooth installation, consistent performance, & demanding operating conditions.

Our copper Y-joints span ¼” to 1⅝” ID with 0.8–1.6 mm walls in equal and reducing forms. Nitrogen purging and RoHS-compliant production maintain clean interiors and eco-safe processes, while premium copper and international standards deliver strength, efficiency, and hassle-free installation for HVAC&R systems globally trusted.

Copper

Y Fittings

FEATURES OF Copper Y Fittings

Precision-Engineered for Leak-Proof

Superior Material & Construction

Optimized for VRF/VRV Systems

Nitrogen-Purged & RoHS Compliant

Rugged Pressure Rating

OUR Products

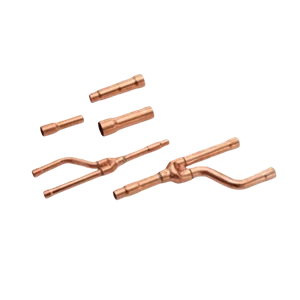

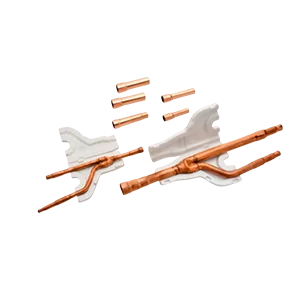

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

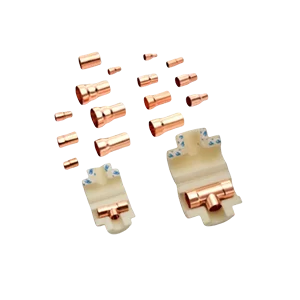

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

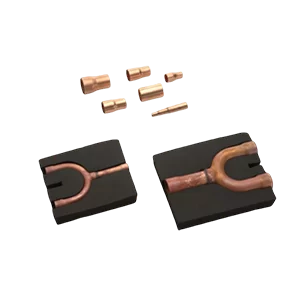

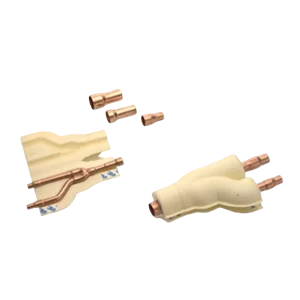

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

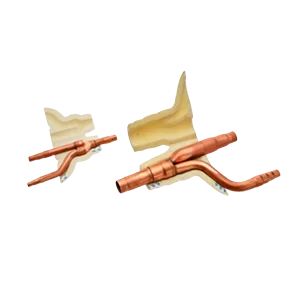

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

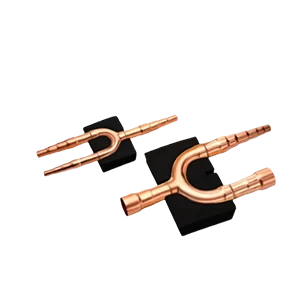

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

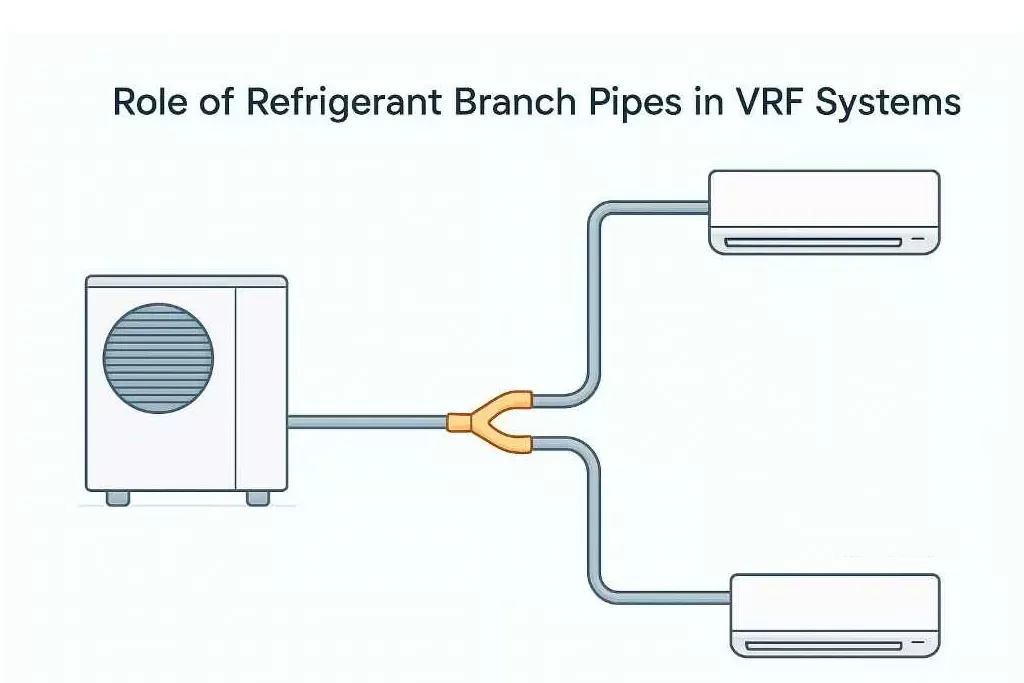

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

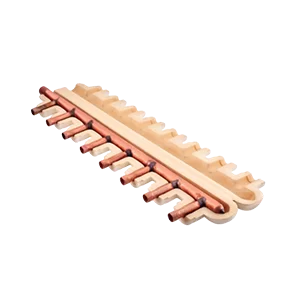

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

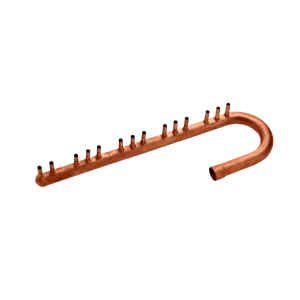

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The precision of these Y-fittings streamlined our installation on a major high-rise project, with zero call-backs for leaks.

Project Manager, Commercial Construction Firm,

UAEAs a specifier, I trust 227 for critical VRF components because their certifications and material traceability are impeccable.

MEP Consultant, Engineering Consultancy,

IndiaTheir ability to deliver customized, non-standard sizes for a heritage building retrofit was exceptional and solved our biggest challenge.

Procurement Head, MEP Contracting,

Saudi ArabiaThe nitrogen-purged feature gives us confidence in system cleanliness, which is non-negotiable for our data center cooling projects.

HVAC Specialist, Critical Systems Integrator,

SingaporeConsistent quality, on-time delivery, and technical support make 227 our go-to supplier for all copper joint requirements.

Operations Director, HVAC Manufacturing,

GermanyOur Blogs

FAq's