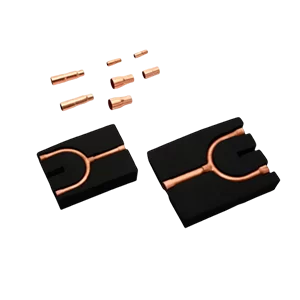

Headers

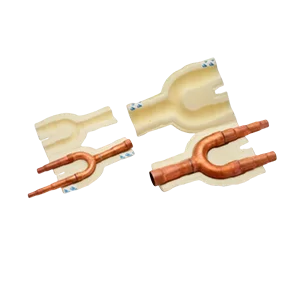

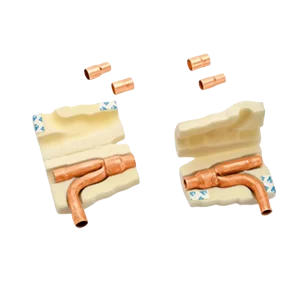

Customized insulation

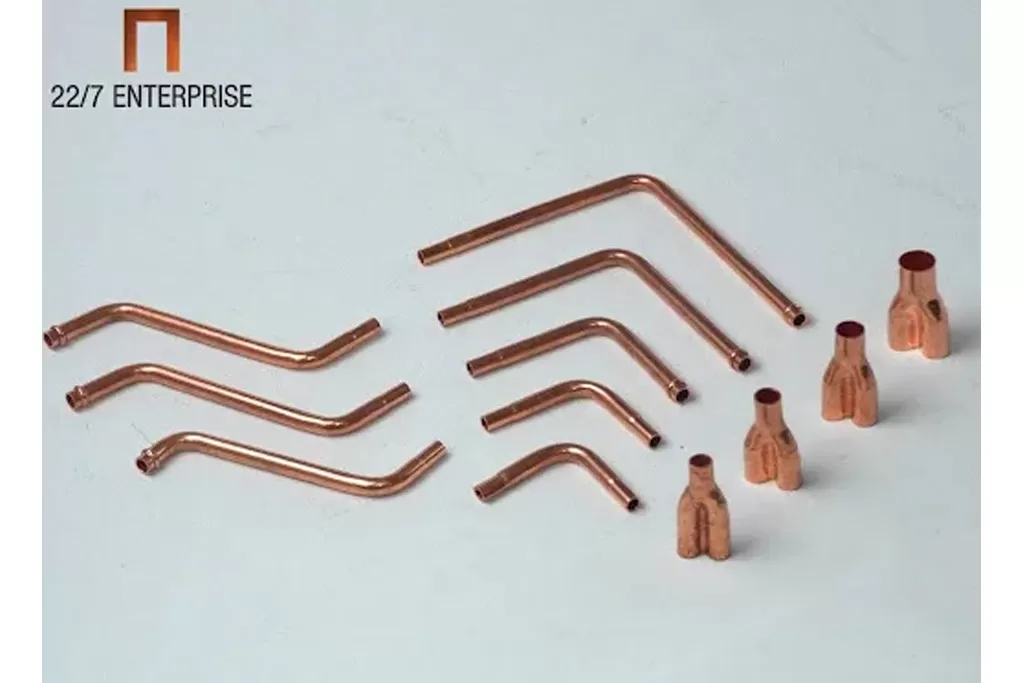

vrf branch piping

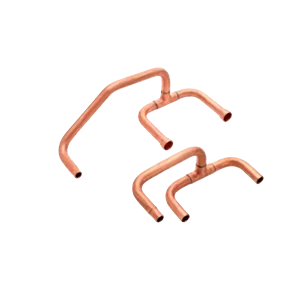

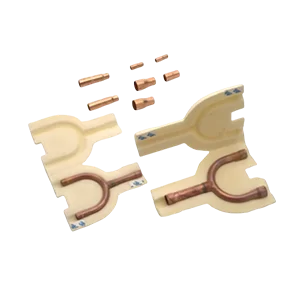

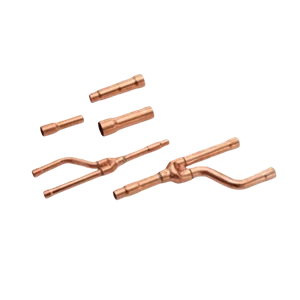

Precision-Engineered VRF Y Joints: Leak-Proof Connections for Multi-Zone Systems

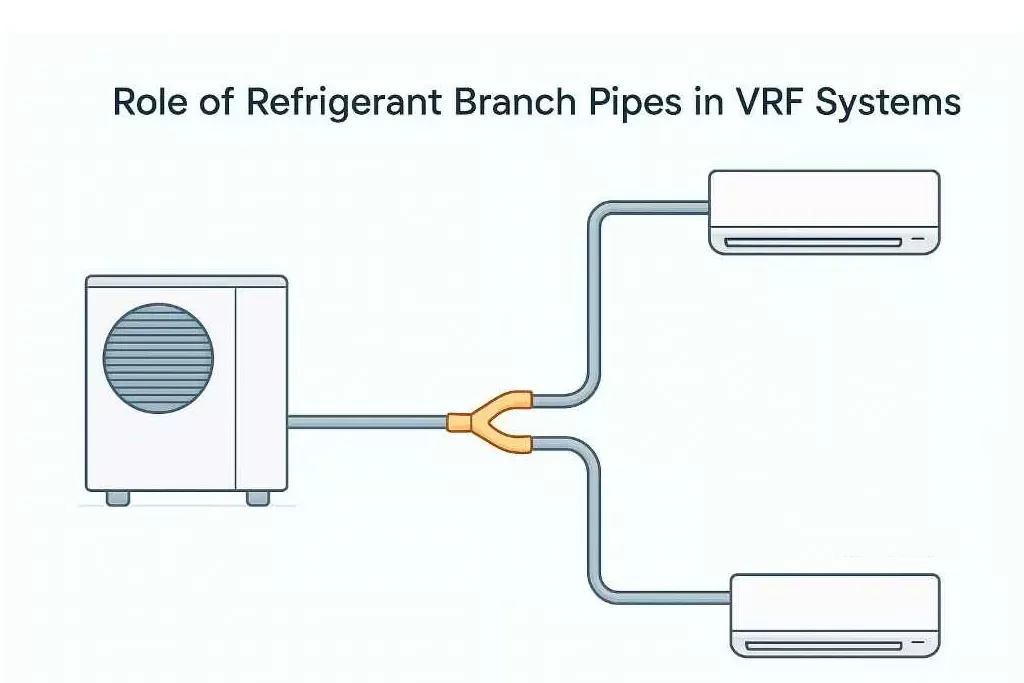

A VRF system sends only the refrigerant that is actually needed in each heating or cooling cycle, letting different air-conditioning zones be controlled at the same time. This keeps power use lower, maintains stable comfort, and allows every space to be set at its own required temperature.

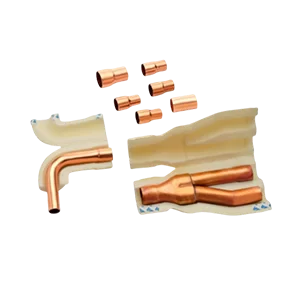

The VRF Branch Piping uses a multi-step design that fits all major VRF systems with ease. Each assembly comes with UV-stabilised fire-grade XLPE insulation to control condensation at refrigerant joints and support long-term service. Every unit is pressure tested at 5.2 MPa, ensuring dependable, leak-free performance and overall system safety.

VRF

branch piping

FEATURES OF vrf branch piping

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE Compliant

Robust Design

OUR Products

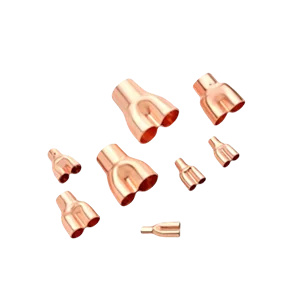

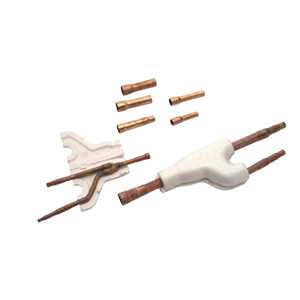

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

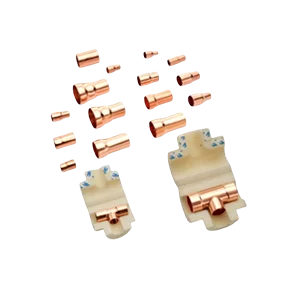

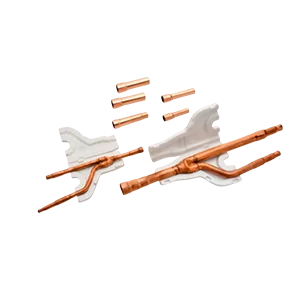

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

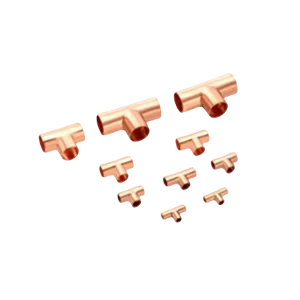

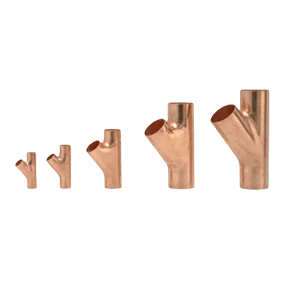

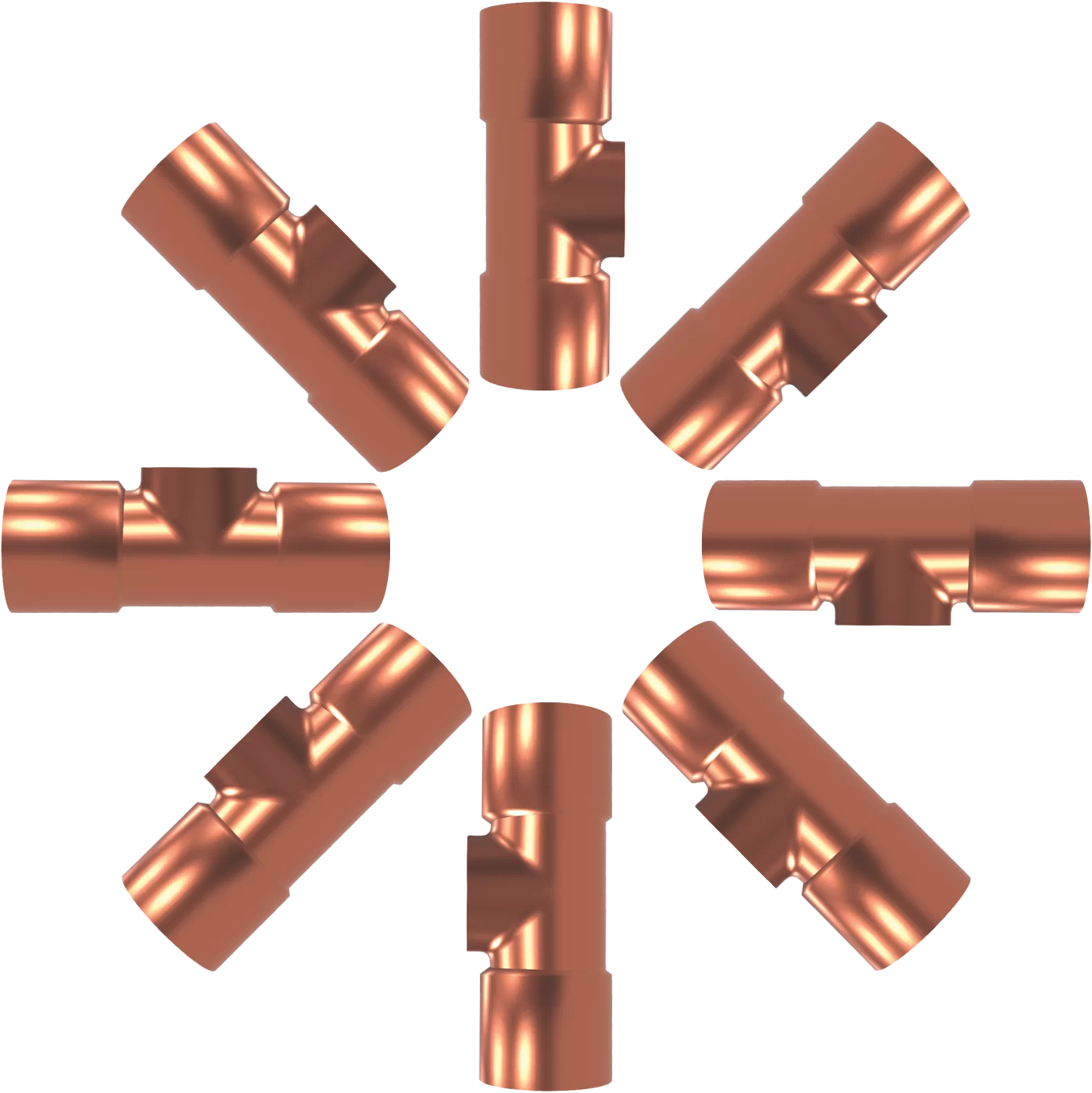

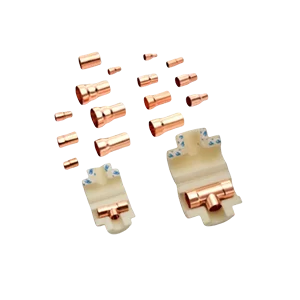

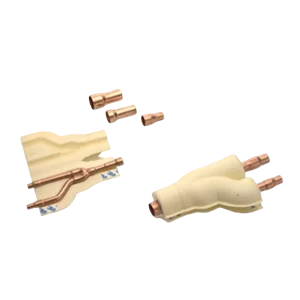

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

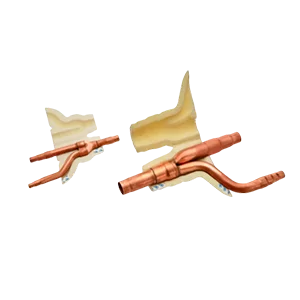

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

AX

Series

Engineered for high-performance R410a and next-generation-ready VRFXR ecosystems

View Details

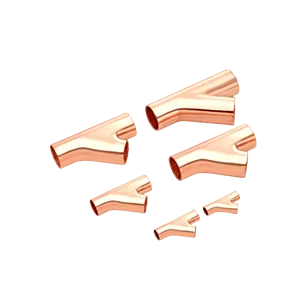

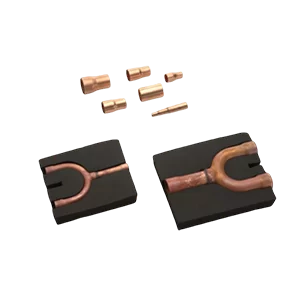

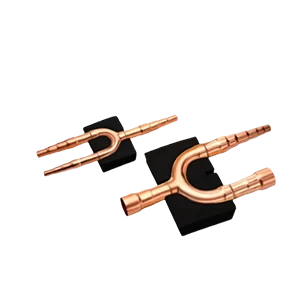

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

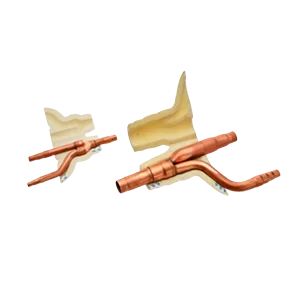

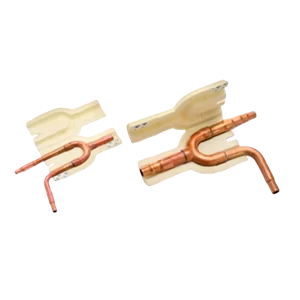

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

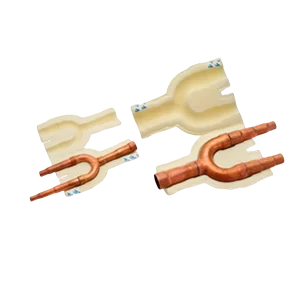

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

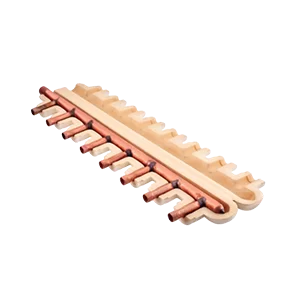

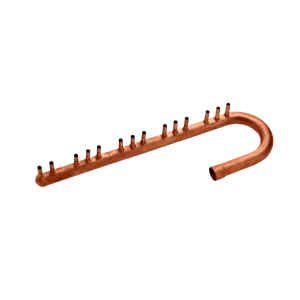

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

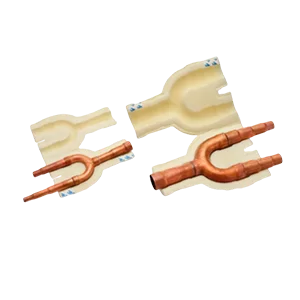

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

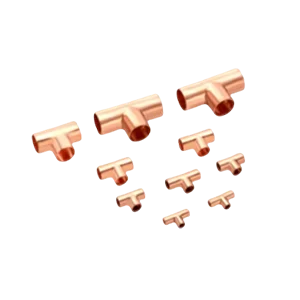

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The traceability code on every joint provides unmatched quality assurance for our mission-critical projects.

Procurement Head, MEP Consultancy,

Saudi ArabiaTheir cross-OEM compatible kits have simplified our inventory and eliminated compatibility worries on-site.

Project Manager, HVAC Contracting Firm,

UAEThe leak-proof guarantee isn't just a claim; it's a promise that has saved us costly post-installation repairs.

Technical Director, Real Estate Developer,

IndiaConsistent on-time delivery of pressure-tested components keeps our complex project schedules on track.

VP Operations, Hotel Chain Developer,

QatarSuperior technical support and custom engineering capabilities for bespoke system layouts.

Design Engineer, Green Building Consultancy,

SingaporeOur Blogs

FAq's

Why would our VRF branch pipe be compatible with other OEM systems?

For our VRF branch piping kits, lead times vary depending on the product type. Our standard, OEM-compatible kits are typically ready for dispatch shortly after order confirmation. For fully bespoke, made-to-order solutions, the process involves design, manufacturing, and testing, which requires a longer lead time. We provide clear timelines for every project and maintain communication throughout the process to ensure reliable delivery without compromising on our high standards of quality.

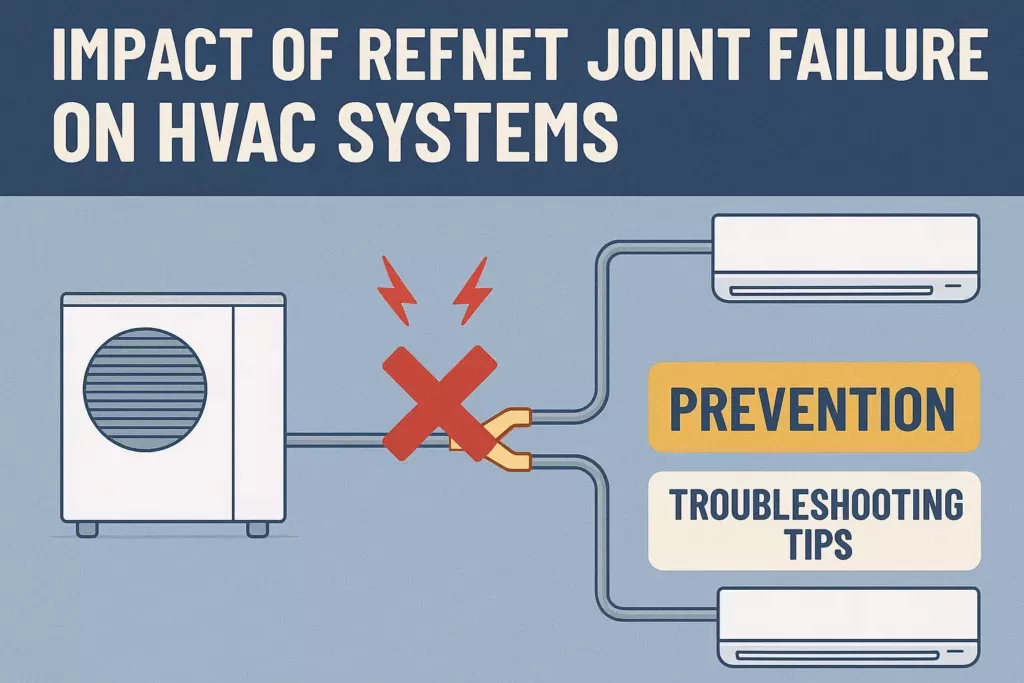

What does the 5.2MPa pressure test do to my VRF system?

The joint is tested in extreme conditions, as the factory test is way over the normal operating pressures. It identifies the possible failures at an early stage, detecting pressure spikes and vibration. The outcome is decades of leak-free and reliable performance that maintains the efficiency and longevity of your system since the first day.

What is the benefit of UV-stabilized, fire-grade XLPE insulation?

This high-quality insulation prevents condensation (commonly referred to as sweating), which is a source of energy waste, and in addition may destroy water-sensitive surfaces. Its UV and fire resistance ensure that it does not tear up in the open or harsh environment. The outcome would be uniform thermal efficiency, enhanced safety and extended dexterity of your VRF system.

Do you offer customized branch piping packages to particular project designs?

Yes. We are experts in tailored engineering. It is with your CAD drawings that we design custom kits: with special headers, lengths, and angles, which are unique to tricky constructions. This best fit accelerates set-up, does away with on-site adjustment timeframes, and provides an accurate and cost-effective answer to non-standard or architecturally challenging projects.

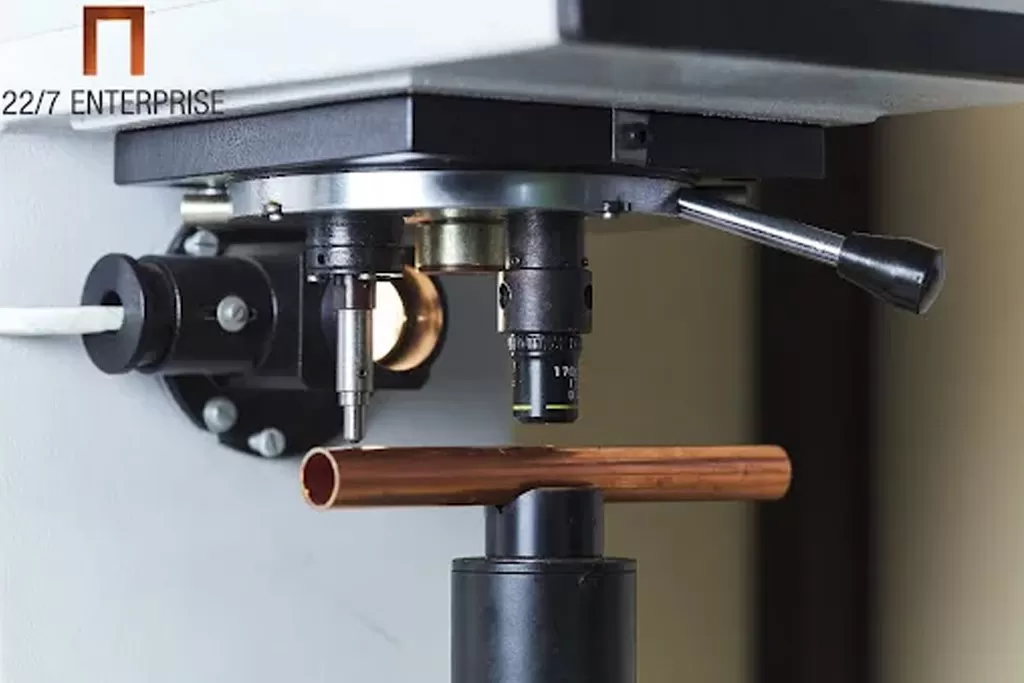

Which quality certifications do you have on your manufacturing processes?

We adhere to ROHS, CE, and ISO 9001: 2015. All copper lots are certified mills, and all production runs are documented to have passed quality checks. These global standards are used to guarantee uniform, dependable and conforming products for local or international projects.

How long is your standard and custom branch piping kit lead time?

Kits that are compatible with Standard OEM are shipped within 7-10 working days. Bespoke solutions take 34 weeks to design, manufacture, and test. We are very clear on timelines, remain on track with you and retain quick turnaround without compromising on quality.

What will guarantee you 100-percent leak proof connection?

We begin with good-quality copper and shape it on precise CNC machines so the fit and finish are always consistent. The brazing is done in a controlled setup using our own alloy, which gives the joints the strength they need without variation from piece to piece. Before anything is cleared for dispatch, every joint is physically checked and pressure-tested to confirm the seal is properly tight. The idea is simple — once it’s installed in the system, it should keep working year after year without becoming a point of concern.

Do you use your branch piping with the newer refrigerant R32 as well as with R410A?

Yes, they’re made to be ready for what’s coming next as well. With good-quality copper, properly done brazing, and the right insulation, they work just as well with R410A as they do with R32. So whether the system being installed is from today or a newer generation, you can expect the same steady performance, safe operation, and long-term reliability.

What backup do you provide in regard to site installation issues?

We provide step-by-step installation guides, technical data sheets and direct accessibility to our engineering department. On-call support or video guidance in order to troubleshoot situations is also offered by us when dealing with major projects. We aim at first-time and error-free installation of our products, within the design specification.

Why is the use of your precision joints better than using the basic VRF system?

Refrigerant flow is balanced by smooth, turbulence-free bores achieved by precision machining. This minimizes pressure drop,s enabling compressors to operate at optimum efficiency. The result includes a decrease in the energy consumption, the cost of electricity, and the operating expenses throughout the life of the system, and the maintenance of uniform comfort in all areas.