VRF

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

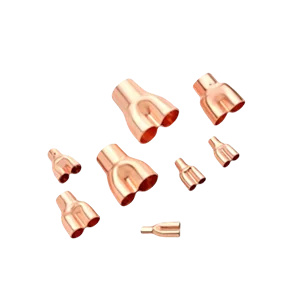

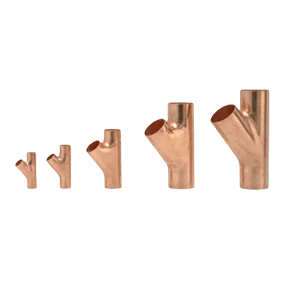

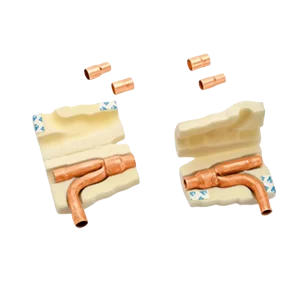

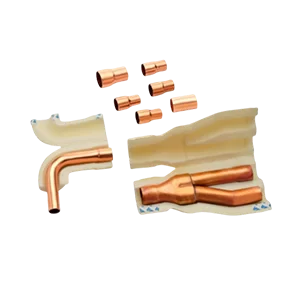

- VRF Y Joint

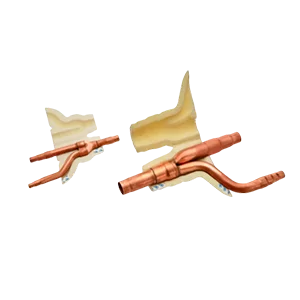

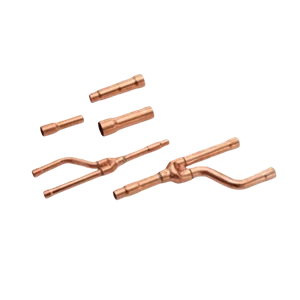

- VRF Branch Piping

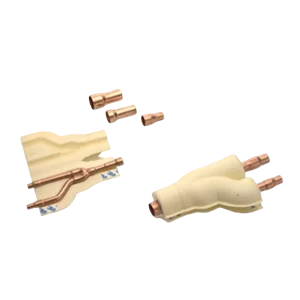

- VRF Refrigerant Branch Piping

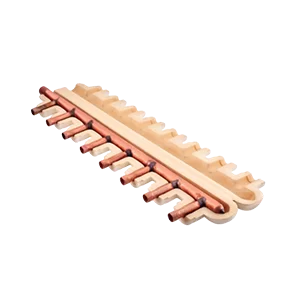

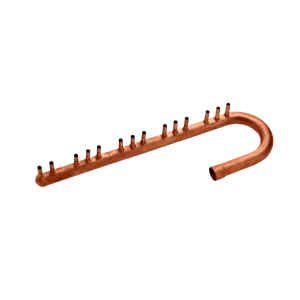

Headers

- SAM Headers

- TA Headers

- Customized Headers

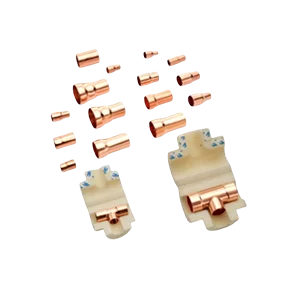

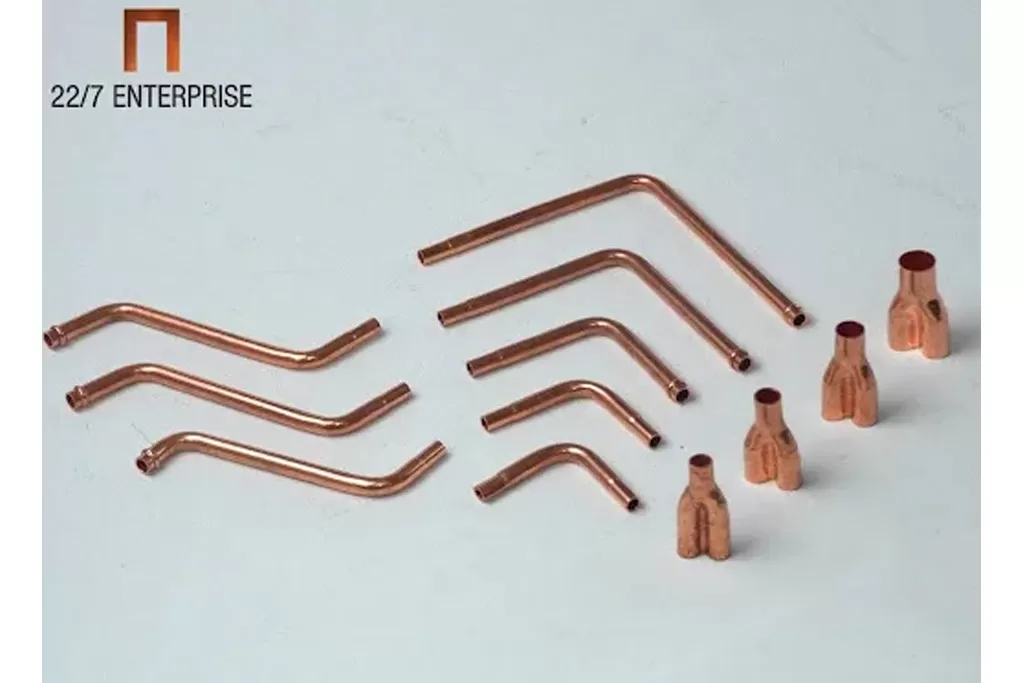

Copper Components

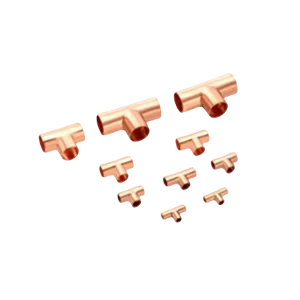

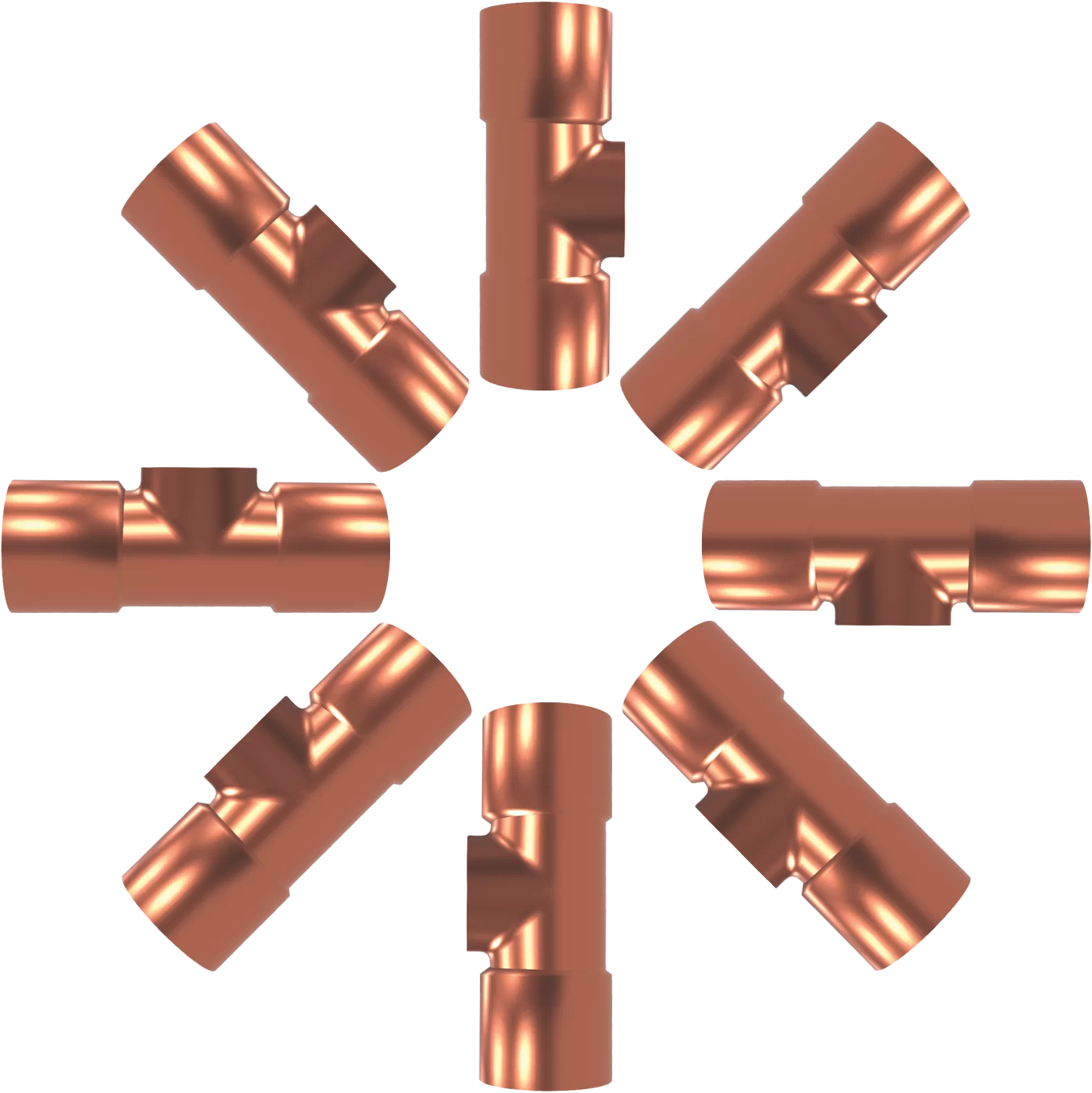

- Copper Compression T Fitting

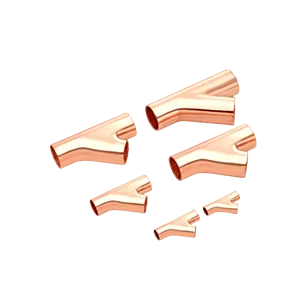

- Copper Y Fitting

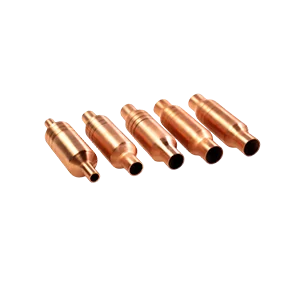

- Strainers

- Mufflers

- Stubs

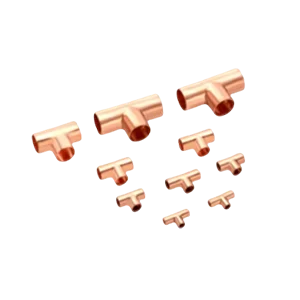

- Commercial Tee's

- Copper Tee Joint

- Y-Type Distributors

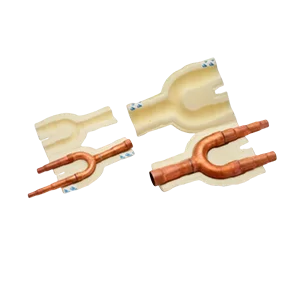

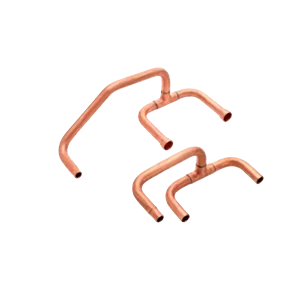

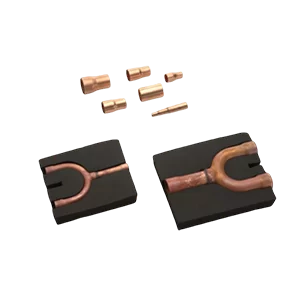

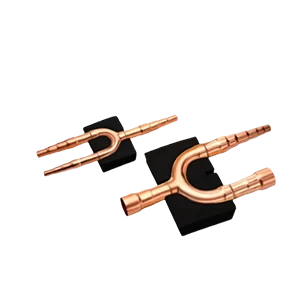

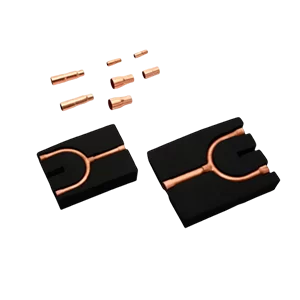

- Unbrazed U & Y Fittings

- Copper Y-Joint

- Tubular Assemblies

Customized insulation

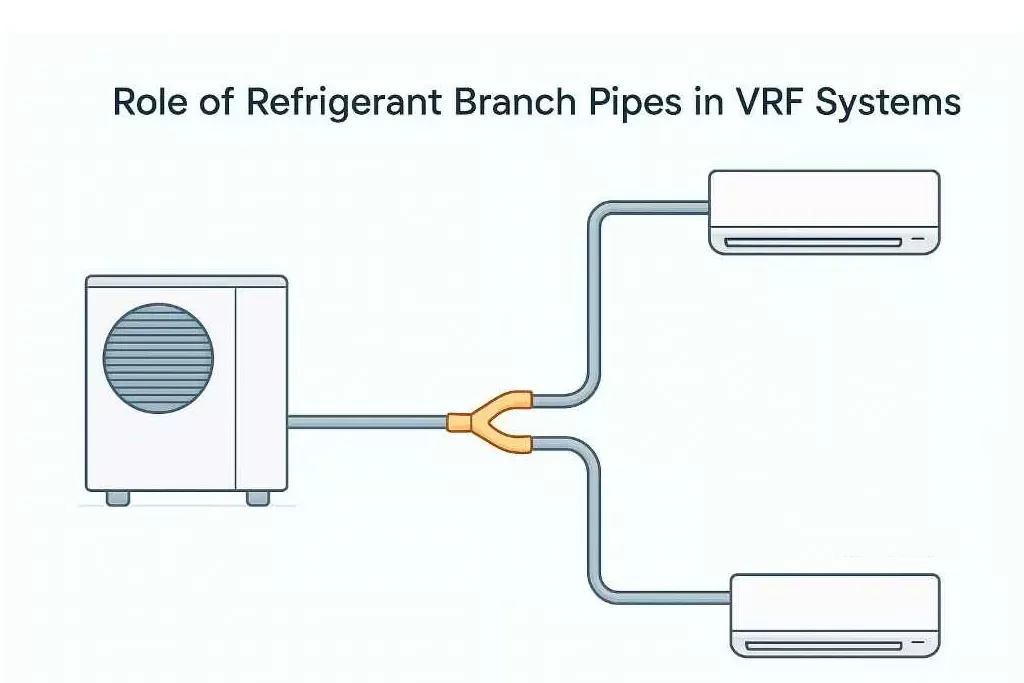

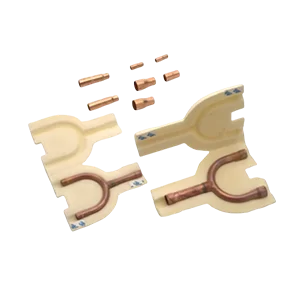

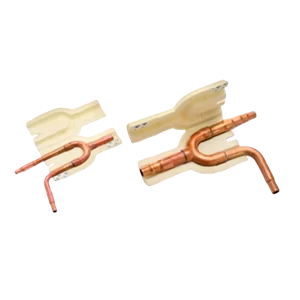

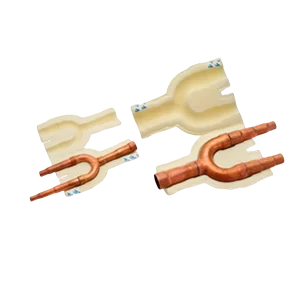

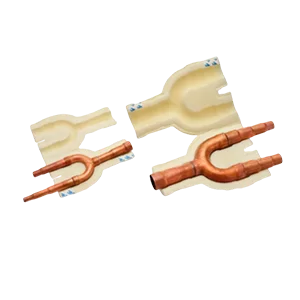

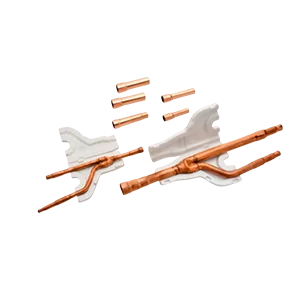

VRF Refrigerant Branch Piping

Advanced VRF Refrigerant Branch Piping for All R410A Systems

VRF Refrigerant

Branch Piping

FEATURES OF VRF Refrigerant Branch Piping

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE Compliant

Robust Design

Product specification (dummy)

| Pipe-A | Pipe-B | Pipe-C | |

|---|---|---|---|

| Pi-KHRP-22T (Gas Side) | 12.7 (1/2) – 15.88 (5/8) – 19.05 (3/4) | 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-22T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35(1/4) | 9.52 (3/8) – 6.35(1/4) |

| Pi-KHRP-33T (Gas Side) | 22.22 (7/8) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-33T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35 (1/4) | 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-72T (Gas Side) | 31.75 (11/4) -28,58 ( 11/8) – 25.4 (1) | 25.4 (1) – 19.05(3/4) – 15.88 (5/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-72T (Liquid Side) | 15.81 (5/8) – 12.7 (1/2) | 12.7 (1/2) – 9.52 (3/8) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-73T (Gas Side) | 38.10 (11/2) – 31.75 (11/4) | 31.75 (11/4) – 28.58 (11/8) – 25.4 (1) | 25.4 (1) – 19.05 (3/4) – 15.88 (5/8) |

| Pi-KHRP-73T (Liquid Side) | 15.88 (5/6) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) |

OUR Products

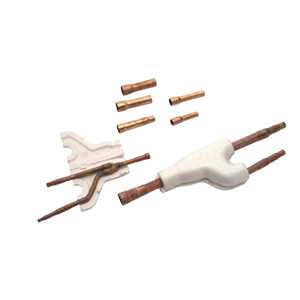

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

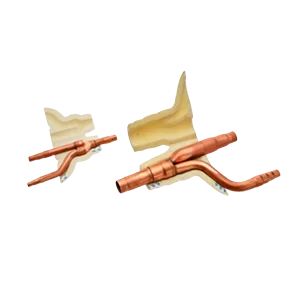

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

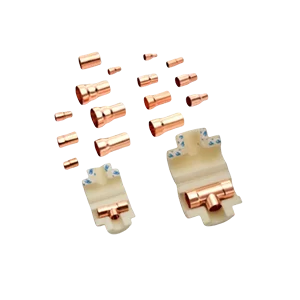

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The traceability and consistent quality of 227's branch pipes have made them our sole supplier for all high-rise projects.

Procurement Head, MEP Consultancy,

Saudi ArabiaTheir custom insulation kits solved a critical condensation issue in our hospital retrofit, showcasing fantastic technical support.

Project Manager, HVAC Contracting,

ItalyWe've achieved a 40% reduction in installation time on site thanks to the pre-fabricated, error-proof kit design.

Green Building Solutions,

SingaporeThe cross-compatibility of their universal series has dramatically simplified our inventory and procurement process.

Operations Director, Facility Management,

UAESwitching to 227 Enterprise components has virtually eliminated callbacks for leaks in our five-year service history.

Owner, Wilson Mechanical,

USAOur Blogs

FAq's

What is VRF Refrigerant Branch Piping?

VRF Refrigerant Branch Piping is the network of pre-insulated copper tubes and precision fittings, like Y-joints and headers, that distribute refrigerant from a single outdoor unit to multiple indoor units. Its hydraulically balanced design ensures efficient, turbulence-free flow and proper oil return, which is critical for system capacity, efficiency, and reliable zoned comfort control.

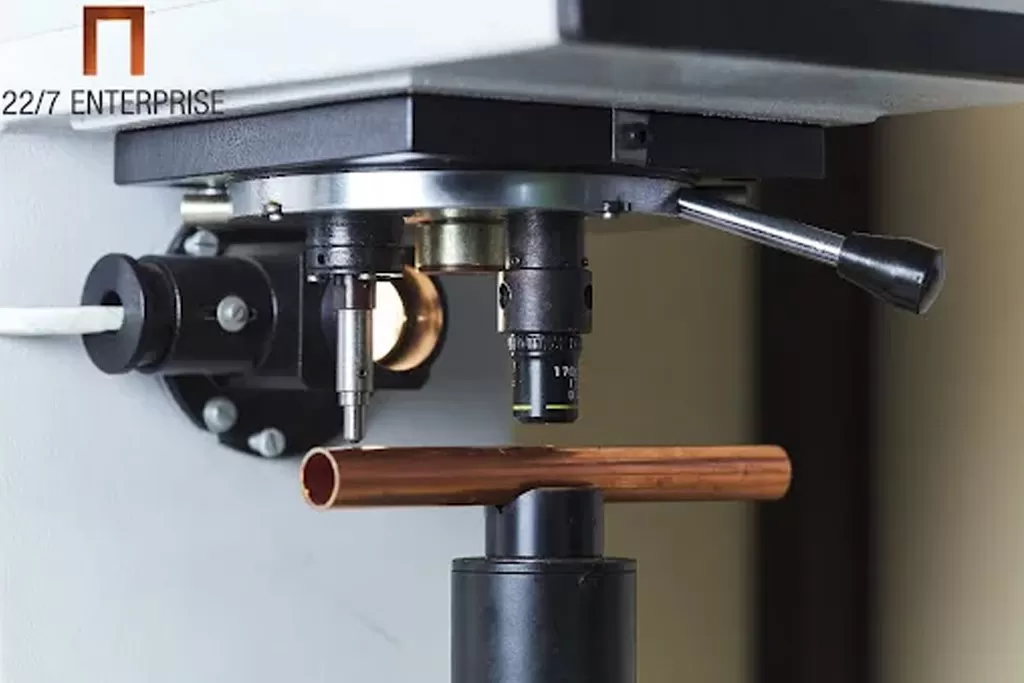

How do you ensure a leak-proof installation?

We ensure leak-proof integrity through superior practices: using nitrogen purge during brazing to prevent oxidation, performing rigorous post-installation pressure testing (e.g., 550 PSI for 24 hours), and pulling a deep vacuum below 500 microns. These steps verify the system's seal against decades of thermal cycling and vibration.

What makes your piping more efficient?

Our piping features a hydraulically balanced design with precision-calcified diameters and smooth inner walls to minimize pressure drop and turbulence. It gives consistent refrigerant flow to all indoor units, allowing the system's inverter compressor to operate at optimal efficiency, which reduces energy consumption and enhances overall system performance and stability.

Why is the high-pressure test (e.g., 5.2 MPa) so important?

Testing at pressures far exceeding normal operating conditions (like 5.2 MPa) is crucial. It proves the joint's integrity under extreme stress, simulating a lifetime of pressure fluctuations, thermal expansion, and vibration. This proactive test is the definitive method for guaranteeing a permanent, leak-free seal for the entire system lifecycle.

What are the key insulation requirements?

Insulation must be closed-cell, with a continuous vapor barrier, and rated for the system's high refrigerant line temperatures (often >120°C). Proper thickness prevents energy loss and condensation, while fire-resistant ratings (like Class O) are needed for safety in plenums. Correct installation is vital for long-term performance and preventing mold.

How does your piping design simplify on-site installation for contractors?

Our kits feature pre-swaged connections, integrated flare nuts, and clear identification markings. This design drastically reduces the number of brazing points required on-site, minimizing both the potential for human error and installation time. The result is faster project completion, lower labor costs, and enhanced reliability from factory-controlled joint integrity.

Are your branch piping components compatible with major OEM systems?

Yes, our components are engineered for full compatibility with all major R410A and R32 VRF systems. We offer OEM-specific series that match the exact hydraulic balance and performance characteristics of your brand and model, ensuring seamless integration and preserving the manufacturer's intended system efficiency and warranty conditions without any compromise.

What certifications guarantee the quality of your piping products?

Our products are manufactured on an ISO 9001:2015 certified line, ensuring consistent quality control. They comply with international ROHS and CE directives for safety and environmental standards. We enforce strict raw material certification and maintain full traceability for every component batch, guaranteeing reliability and performance from production to installation.

Can you provide customized piping solutions for unique project layouts?

Absolutely. We specialize in custom engineering for complex projects. Our team designs tailored solutions, such as custom multi-port headers, specific separator tube lengths, and unique assembly configurations, to meet spatial constraints or performance demands of non-standard installations, ensuring optimal system function even in the most challenging architectural environments.

What technical support do you offer after the sale?

We provide comprehensive after-sales support, including detailed datasheets, step-by-step installation guides, and direct access to our engineering team for consultation. This ensures proper installation, system optimization, and long-term reliability. Our commitment is to be a technical partner for the lifespan of your VRF system.