VRF

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

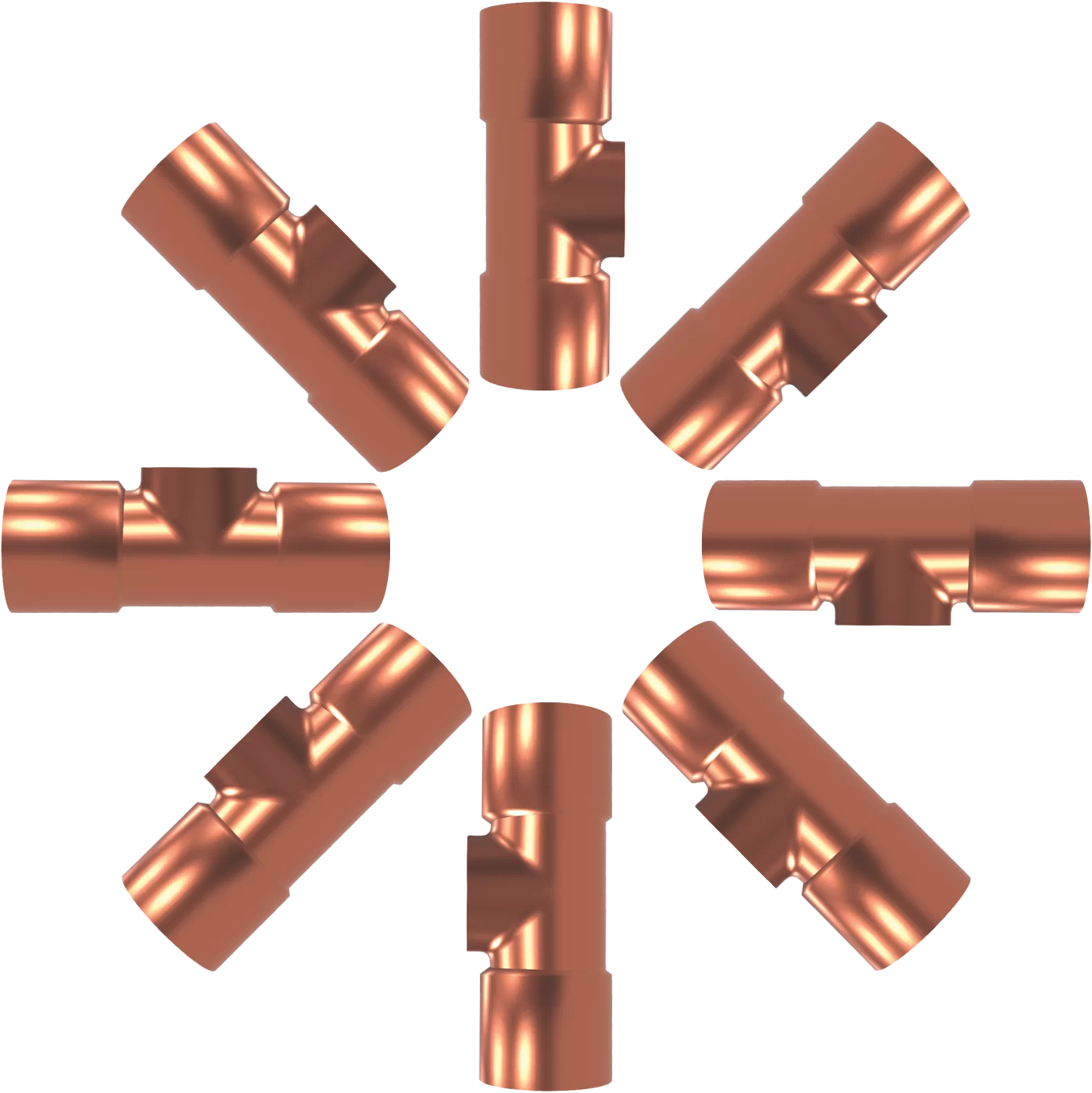

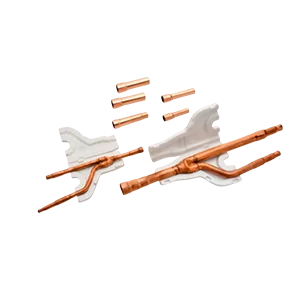

- VRF Y Joint

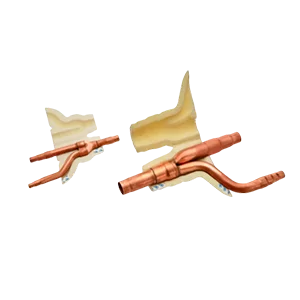

- VRF Branch Piping

- VRF Refrigerant Branch Piping

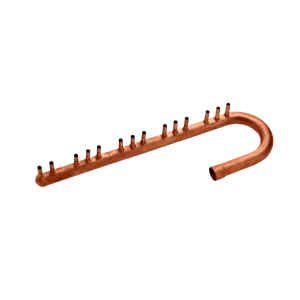

Headers

- SAM Headers

- TA Headers

- Customized Headers

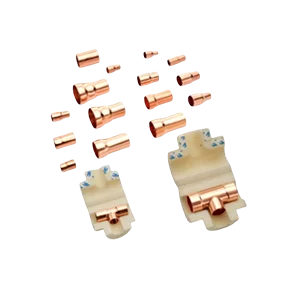

Copper Components

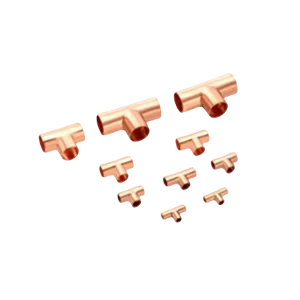

- Copper Compression T Fitting

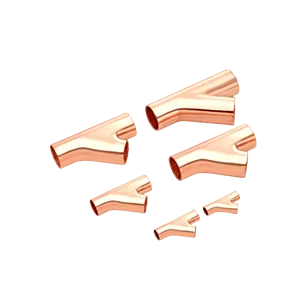

- Copper Y Fitting

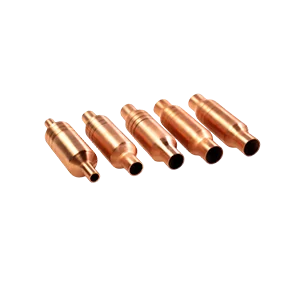

- Strainers

- Mufflers

- Stubs

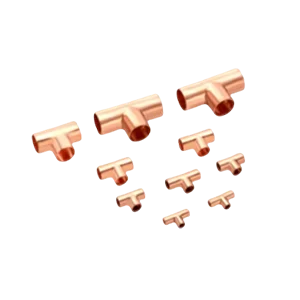

- Commercial Tee's

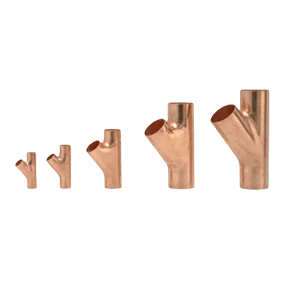

- Copper Tee Joint

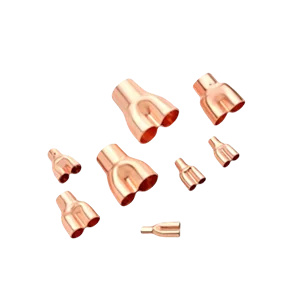

- Y-Type Distributors

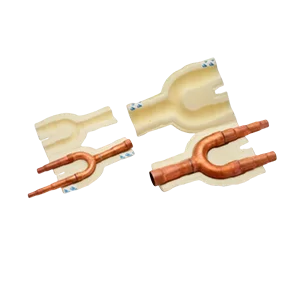

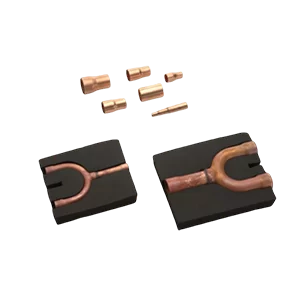

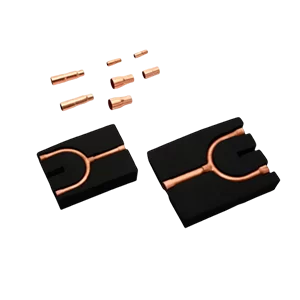

- Unbrazed U & Y Fittings

- Copper Y-Joint

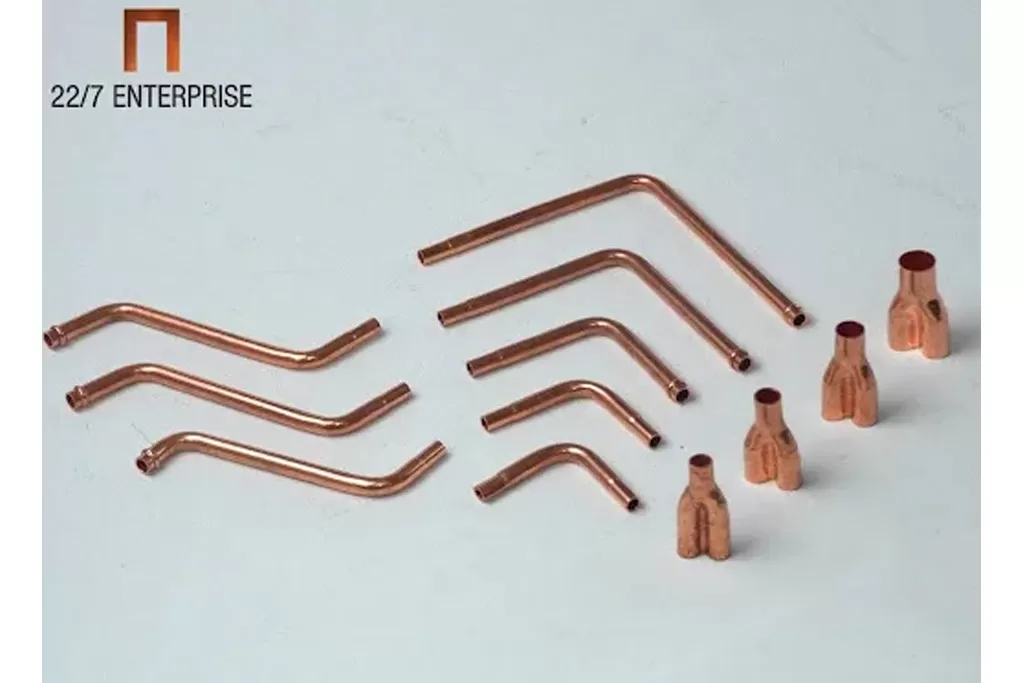

- Tubular Assemblies

Customized insulation

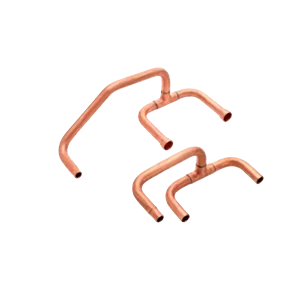

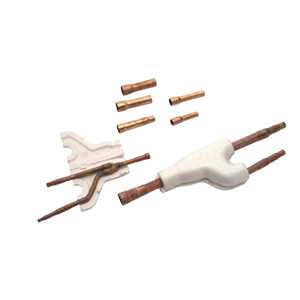

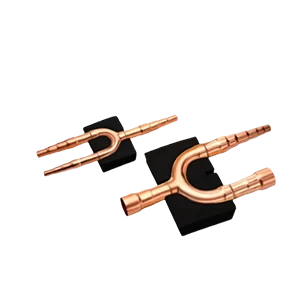

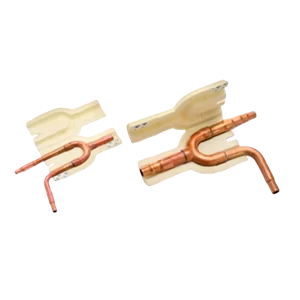

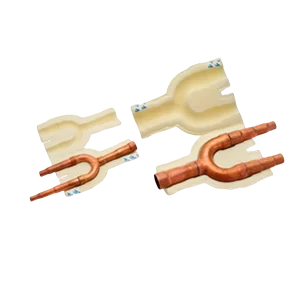

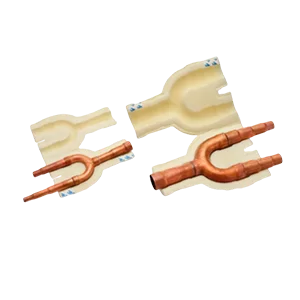

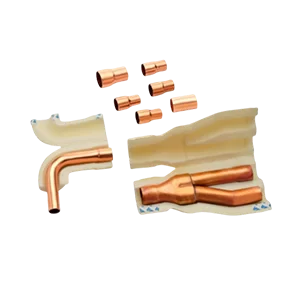

VRF Y Joint

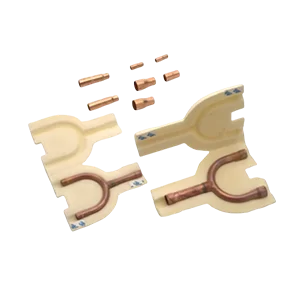

Precision-Engineered VRF Y Joints for Unmatched System Integrity & Flow Efficiency

VRF

Y Joint

FEATURES OF VRF Y Joint

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE Compliant

Robust Design

Product specification

| Pipe-A | Pipe-B | Pipe-C | |

|---|---|---|---|

| Pi-FQRP-U-01 (Gas Side) | 12.7 (1/2) -15.88 (5/8) – 19.05(3/4) – 25.4 (1) – 22.2 (7/8) | 22.2 (7/8) – 19.05 (3/4) – 15.88(5/8) – 12.7 (1/2) – 9.52 (3/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) |

| Pi-FQRP-U-01 A(Liquid Side) | 9.52 (3/8) – 12.7 (1/2) | 9.52 (3/8) – 6.5 (1/4) | 9.52 (3/8) – 6.5 (1/4) |

| Pi-FQRP-U-02 (Gas Side) | 28.58 (11/8) – 25.4 (1)– 22.2 (7/8) | 22.22 (7/8) – 19.05 (3/4)– 15.88 (5/8) – 12.7 (1/2) | 22.22 (7/8) – 19.05 (3/4) – 15.88(5/8) – 12.7 (1/2) – 9.52 (3/8) |

| Pi-FQRP-U-02 (Liquid Side) | 9.52 (3/8) – 12.7 (1/2) – 15.88 (5/8) | 15.88 (5/8) – 12.7(1/2) – 9.52 (3/80) – 6.35 (1/ 4) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/80– 6.35 (1/ 4) |

| Pi-FQRP-U-03 (Gas Side) | 25.4 (1) – 31.75 (11/4) – 28.58 (11/8) | 28.58 (11/8) – 25.4 (1) – 22.2(7/8) – 19.05 (3/4) – 15.88 (5/8) | 28.58 (11/8) – 25.4 (1) – 22.2 (7/8) – 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) |

| Pi-FQRP-U-03 (Liquid Side) | 15.88 (5/8) – 19.05 (3/4)– 22.2(7/8) – 25.4 (1) – 22.2 (7/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) |

| Pi-FQRP-U-04 (Gas Side) | 41.28 (15/8) – 38.10 (11/2) – 34.93 (13/8) – 31.75 (11/4) | 38.10 (11/2) – 41.28 (15/8) – 34.93(13/8) – 31.75 (11/4) – 28.58 (11/8)– 25.4 (1) – 22.2 (7/8) – 19.05 (3/4) | 38.10 (11/2) – 34.93 (13/8) – 31.75 (11/4) – 28.58 (11/8) – 25.4 (1) – 22.2 (7/8) – 19.05 (3/4) |

| Pi-FQRP-U-04 (Liquid Side) | 15.88 (5/8) – 19.05 (3/4) – 22.2(7/8) – 25.4 (1) – 22.2 (7/8) | 22.2 (7/8) – 19.05 (3/4) – 15,88(5/8)– 12.7 (1/2) – 9.52 (3/8) | 22.2 (7/8) – 19.05(3/4) – 15,88(5/8) – 12.7 (1/2) – 9.52 (3/8) |

OUR Products

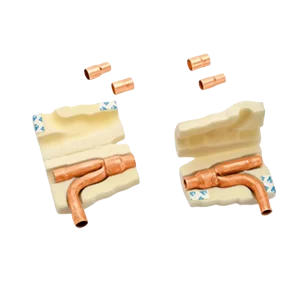

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

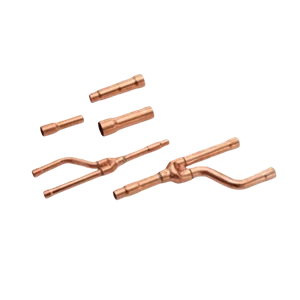

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

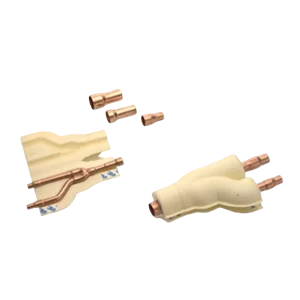

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

VRF Y

Joint

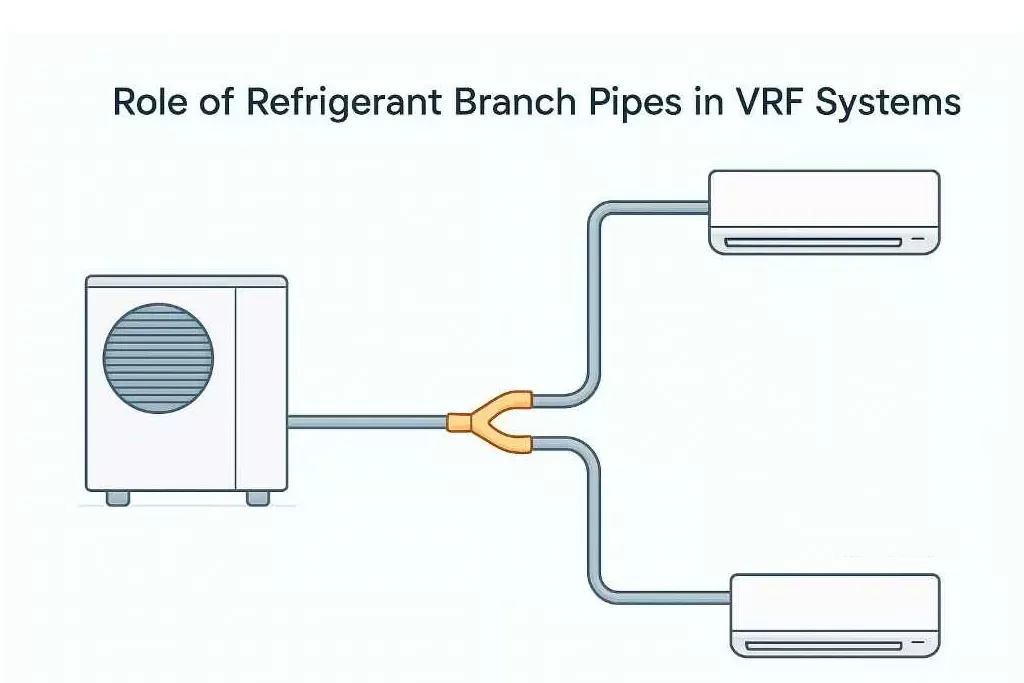

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

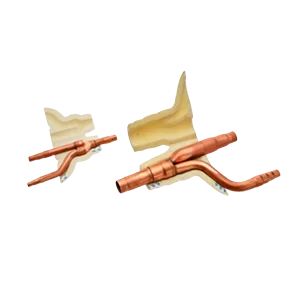

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

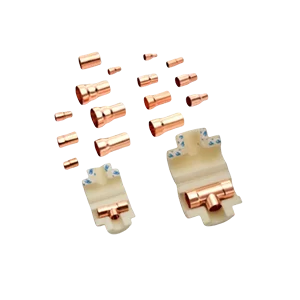

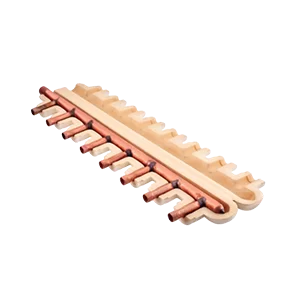

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

These joints are completely customizable with size, shape, insulation, such as XLPE or nitrile rubber, minimum order none. With our 55,000 sq. ft. factory, we can trace everything, hence you have reliability that will protect the energy consumption of your system and allow it to last a long time.

Testimonial's

The dimensional accuracy of these Y-joints made our large-scale hotel installation remarkably smooth.

Project Director, Hospitality Construction,

UAEZero leak incidents since switching to 227 Enterprise for our premium residential projects.

Procurement Head, MEP Consultancy,

Saudi ArabiaTheir custom insulation options solved our specific condensation challenges in a high-humidity environment.

Senior Engineer, Marine Infrastructure,

IndiaThe consistent quality and on-time delivery have made them a trusted partner for our HVAC distribution network.

Operations Manager, HVAC Distributor,

Southeast AsiaUsing their ROHS-compliant joints was crucial for meeting our project's stringent sustainability standards.

Sustainability Lead, Green Building Consultancy,

EuropeOur Blogs

FAq's

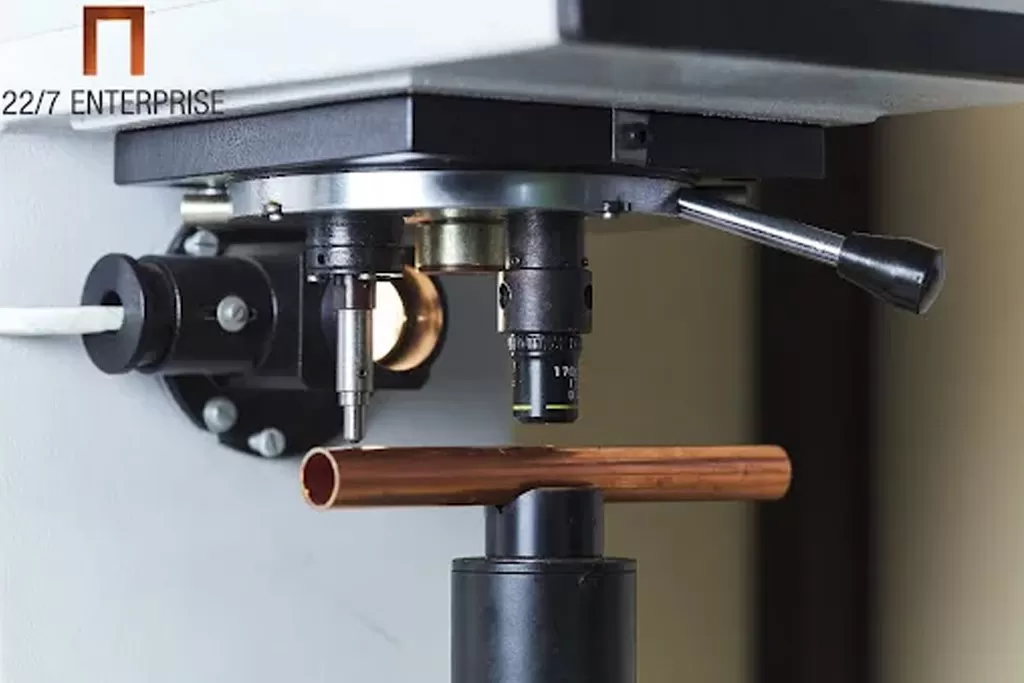

Which quality of copper do you use in your VRF Y-Joints?

Our copper is of premium C1220 (DHP), which is JIS H3300 certified. It is a high-phosphorus deoxidized material that prevents rust and oxidation, provides excellent brazing, is long-lasting, and remains solid at the high-pressure, high-vibration vibes of the current R410A VRF and VRV systems.

What do you do to make sure your Y-Joints are 100 percent leak-proof?

Each joint is given an assassin 100 per cent final check and a 5.2 Mpa inert gas hydrostatic test. Automatically braze the connections, too, therefore all your seals are perfect and will remain solid throughout the lifetime of your VRF system.

Will your Y-Joint fit my specific brand of VRF system?

Yes, absolutely. Our universal Y-Joints are engineered to the same OEM standards and are compatible with all major VRF brands. They are designed as a direct, plug-and-play component that ensures a perfect fit, maintains system integrity, and does not void manufacturer warranties. You can install with confidence, knowing it's a certified and reliable solution for your specific system.

Do you offer custom or programmed Y-Joints?

Totally. We can custom-fabricate Y-Joints in any size combinations that you desire: any inlet/outlet combinations, branch angles of 45 or 90, any unusual hookups, or special configurations to suit your piping design- Y-Joints fit your piping schematic perfectly.

What are the choices of insulation for the branch piping kits?

In our kits, we have personal insulation. Use top fire safety with grab Class O nitrile rubber, or XLPE that is used when you need super heat and moisture resistance, or EPS when you have a budget constraint. They are all precision-cut and thus fit easily around the joints.

Please enter your minimum order quantity (MOQ)?

No minimum order at all. You may have only one when you are replacing an item, or you may have a great deal when you are working on a grand scale-anything you need we have.

What is the effect of quality Y-Joint on the efficiency of VRF systems in general?

A solid Y-Joint reduces the turbulence and pressure loss of refrigerants; therefore, the flow is balanced. Each room unit operates at its optimum, switches between heat more efficiently, relieves the compressor burden and reduces energy consumption significantly- saves money.

What are the certifications of your products and processes?

We’re ROHS and CE compliant. We have an ISO 9001:2015-based factory that adheres to such strict standards as ASME B16.22. It implies that all components can be traced, safe, and comply with all the international HVAC regulations.

How long is the average dispatching time following the confirmation of the order?

In the case of ordinary goods, we stock them to enable us to deliver within 24-48 hours. In case it is custom or large, we inform you of the lead time immediately so that your schedule does not go off.

What do I do to ask someone to quote me or offer any technical support on my project?

Contact us: Sales: hit us up at [email protected] Tech help: Give us the brand, model, sizes/qty required and project details to enable us give you a perfect reply and assist you throughout.