VRF

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

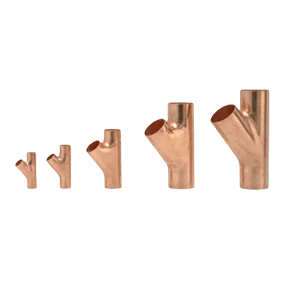

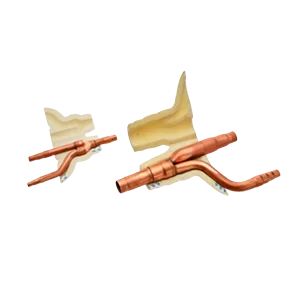

- VRF Y Joint

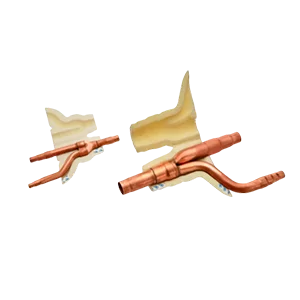

- VRF Branch Piping

- VRF Refrigerant Branch Piping

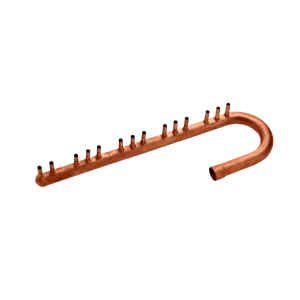

Headers

- SAM Headers

- TA Headers

- Customized Headers

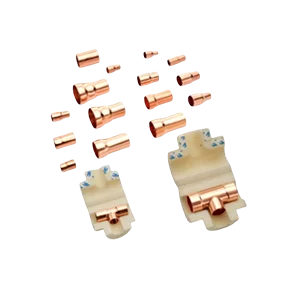

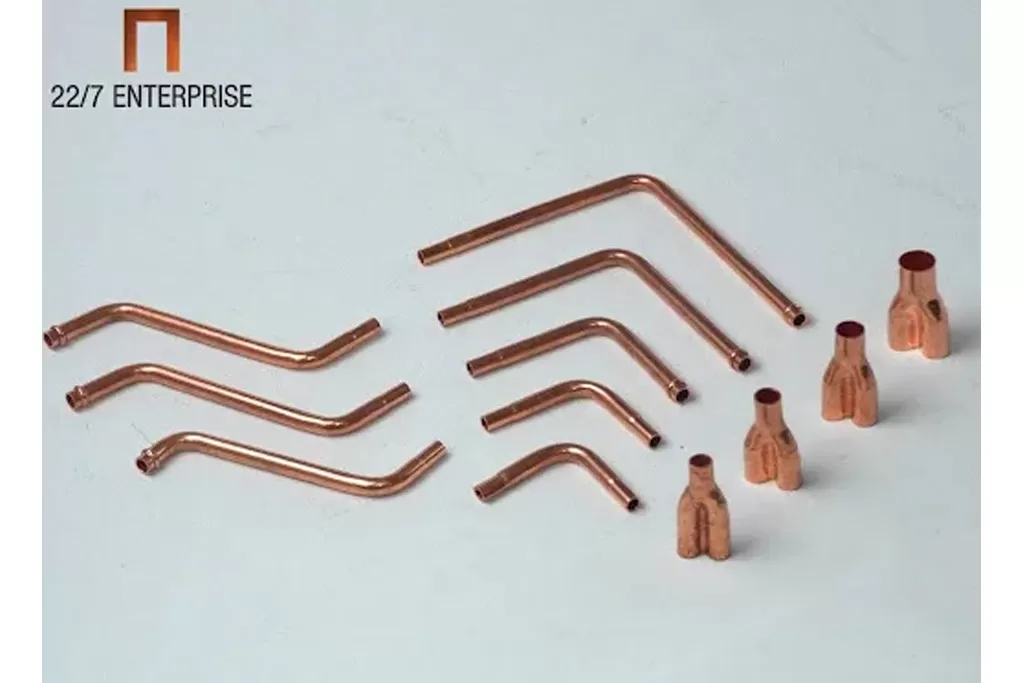

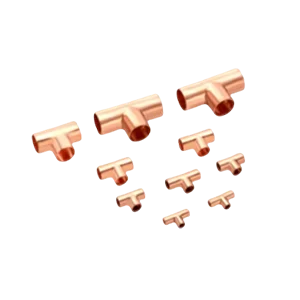

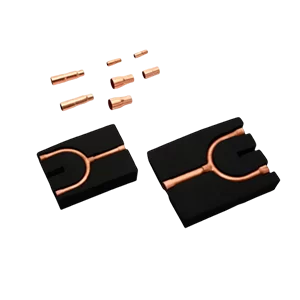

Copper Components

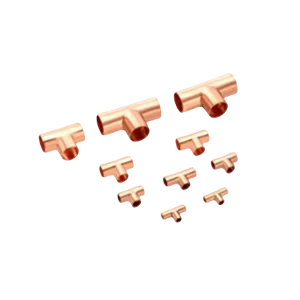

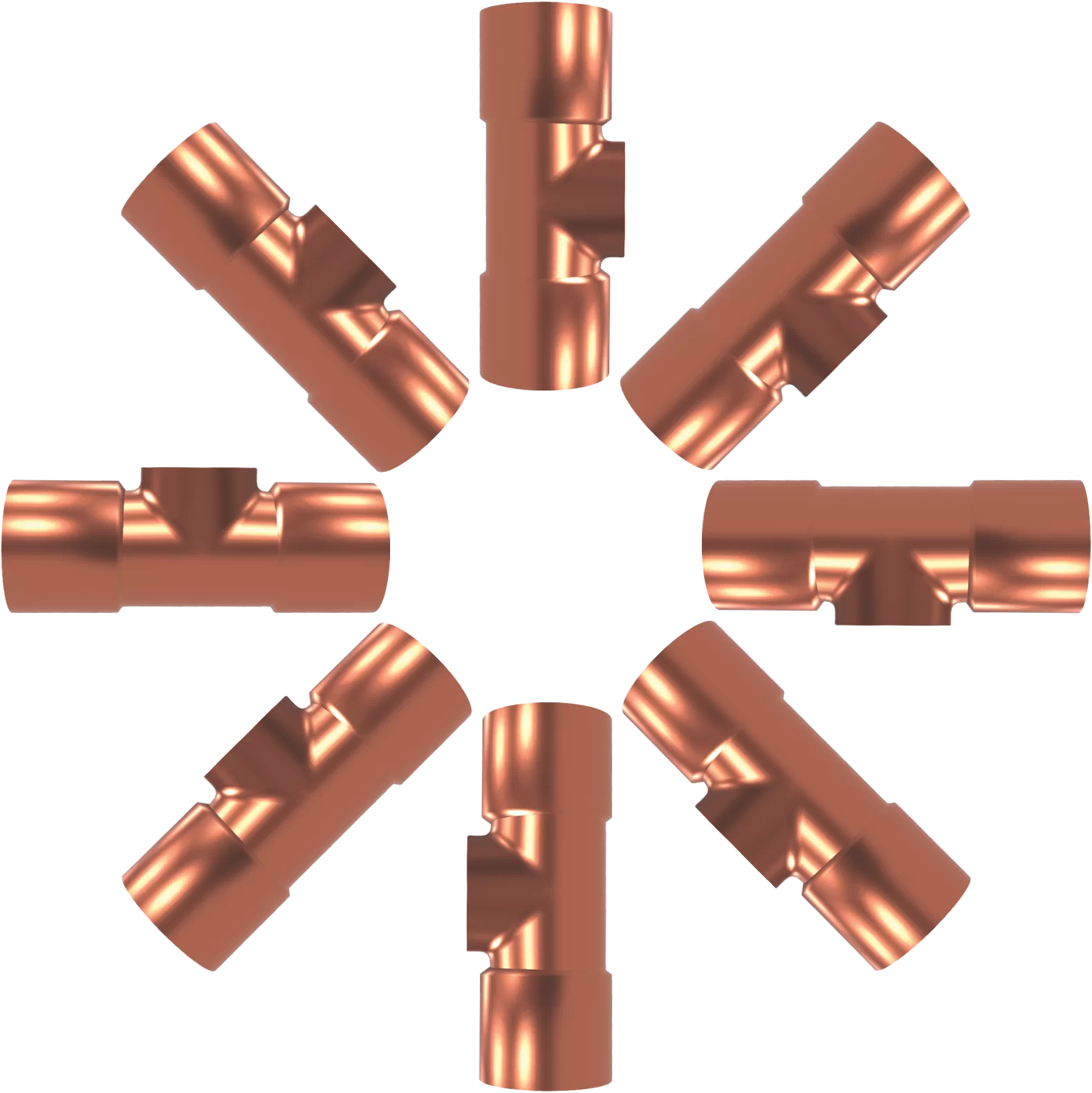

- Copper Compression T Fitting

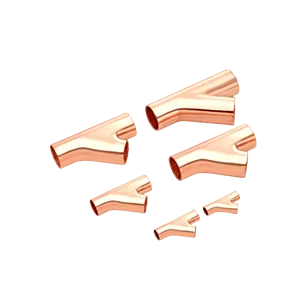

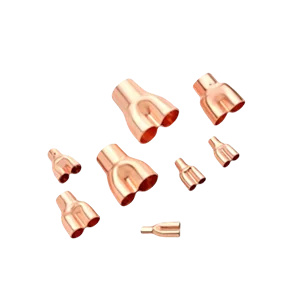

- Copper Y Fitting

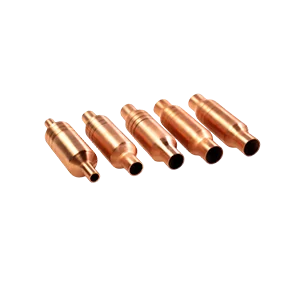

- Strainers

- Mufflers

- Stubs

- Commercial Tee's

- Copper Tee Joint

- Y-Type Distributors

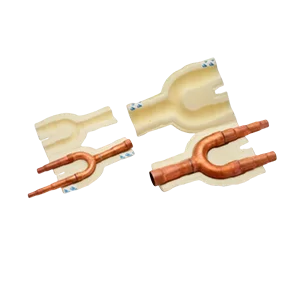

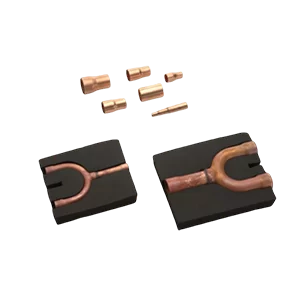

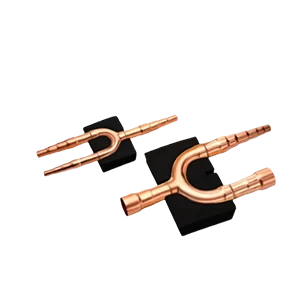

- Unbrazed U & Y Fittings

- Copper Y-Joint

- Tubular Assemblies

Customized insulation

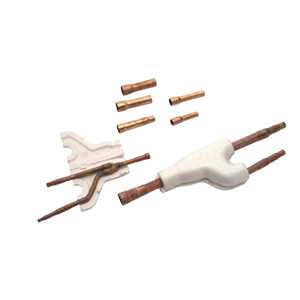

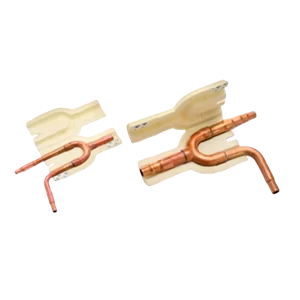

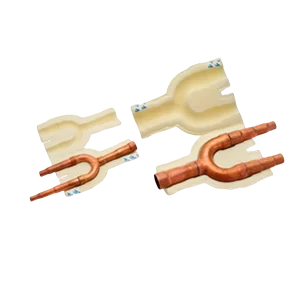

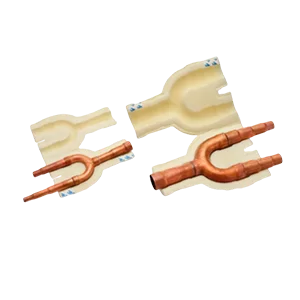

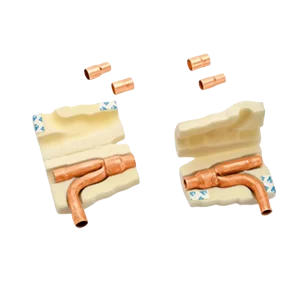

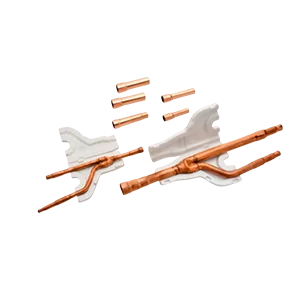

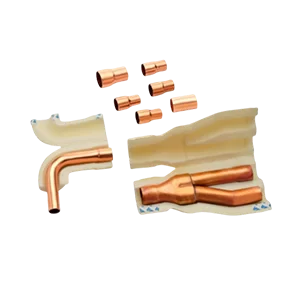

TA Series

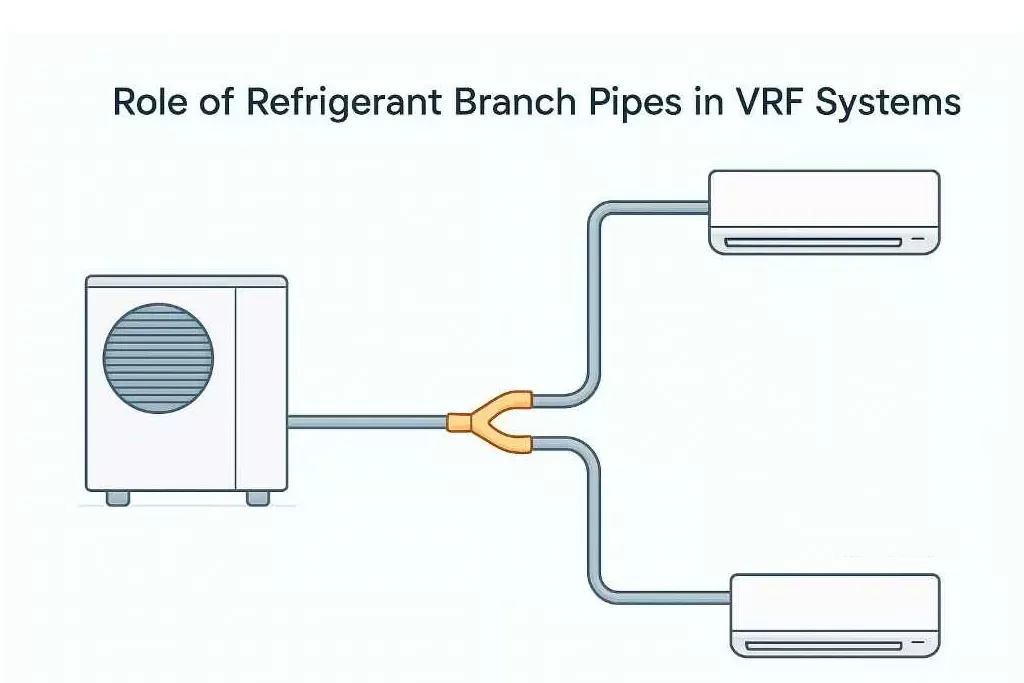

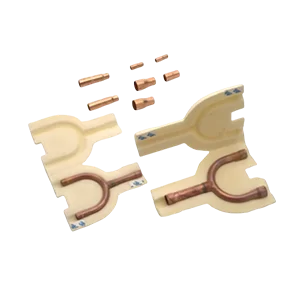

Master the Flow of Comfort and Efficiency with Our Premium VRF Branch Piping Kit for R410a Systems.

TA Series VRF Y joints are vital to system performance, directing refrigerant evenly between outdoor and indoor units for stable operation. By maintaining balanced flow, they help reduce energy consumption, support consistent cooling across multiple zones, and keep overall comfort levels steady in demanding installations.

TA Series VRF Y joints maintain correct refrigerant movement between outdoor and indoor units, allowing the system to operate smoothly and with better energy control. They help achieve stable performance, quieter operation, balanced temperature in every zone, and dependable comfort across varied load conditions in large installations.

TA

Series

FEATURES OF TA SERIES

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE compliant

Robust industrial-grade design

Product specification

| Pipe-A | Pipe-B | Pipe-C | Reducer Sets | |

|---|---|---|---|---|

| Pi-RBM-55E (Gas Side) | 15.88 (5/8) | 15.88 (5/8) | 15.88 (5/8) | 2, 3×2, 15×2 |

| Pi-RBM-55E (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) | 9.52 (3/8) | 1×2 |

| Pi-RBM-105E (Gas Side) | 22.22 (7/8) | 22.22 (7/8) | 22.22 (7/8) | 15, 4×2, 5×2 |

| Pi-RBM-105E (Liquid Side) | 15.88 (5/8) | 15.88 (5/8) | 15.88 (5/8) | 2, 15, 16 |

| Pi-RBM-205E (Gas Side) | 21.75 (11/4) | 28.58 (11/8) | 28.58 (11/8) | 6, 7×2, 8, 9, 10, 15 |

| Pi-RBM-205E (Liquid Side) | 15.88 (5/8) | 15.88 (5/8) | 15.88 (5/8) | 2, 3×2, 16 |

| Pi-RBM-305E (Gas Side) | 81.10 (11/2) | 81.10 (11/2) | 81.10 (11/2) | 7, 11, 12×2, 13×3, 14×2, 15 |

| Pi-RBM-305E (Liquid Side) | 22.22 (7/8) | 22.22 (7/8) | 22.22 (7/8) | 15, 16, 17×2 |

Reducer no. & size

| 1 | OD 9.52 (3/8) – 6.35 (1/4) |

| 2 | OD 15.88 (5/8) x 12.7(1/2) |

| 3 | OD 15.88 (5/8) x 19.05 (3/4) |

| 4 | OD 22.22 (7/8) x 15.88 (5/8) |

| 5 | OD 22.22 (7/8) x 28.58 (11/8) |

| 6 | OD 28.58 (11/8) x 15.88 (5/8) |

| 7 | OD 28.58 (11/8) x 22.2 (7/8) |

| 8 | OD 28.58 (11/8) x 34.93 (13/8) |

| 9 | OD 31.75 (11/4) x 28.58 (11/8) |

| 10 | OD 31.75 (11/4) x 34.93 (13/8) |

| 11 | OD 38.1 (11/2) x 15.88 (5/8) |

| 12 | OD 38.1 (11/2) x 28.58 (11/8) |

| 13 | OD 38.1 (11/2) x 34.93 (13/8) |

| 14 | OD 38.1 (11/2) x 41.28 (15/8) |

| 15 | OD 15.88 (5/8) x 12.7 (1/2) x 9.52 (3/8) |

| 16 | OD 15.88 (5/8) x 12.7 (1/2) x 9.52 (3/8) x 6.35 (1/4) |

| 17 | OD 222 (7/8) x 19.05 (3/4) x15.88 (5/8) |

OUR Products

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

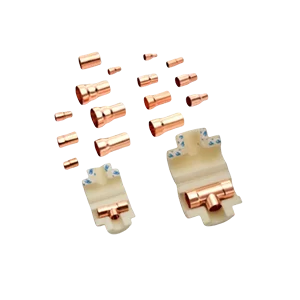

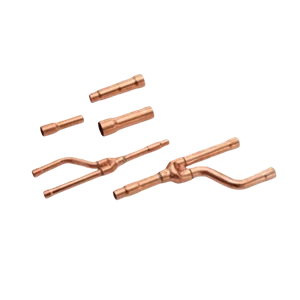

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

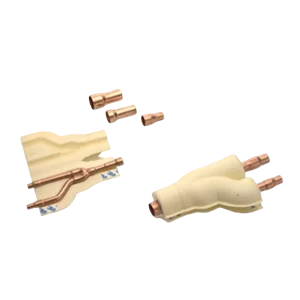

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

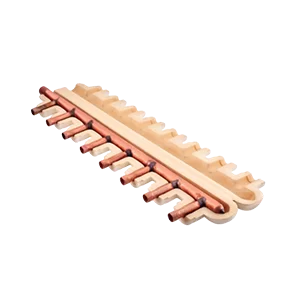

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

TA Series copper branch piping kits improved our installation precision and eliminated joint rework on multiple projects

Project Manager, Luxury Hotel Developer,

UAEThe reliability is unmatched. It's the only component we specify for high-rise MEP projects now

Lead Engineer, MEP Consultancy,

SingaporeSuperior internal finish compared to other brands, which we believe contributes to better system balance and efficiency.

Procurement Head, HVAC Contracting Firm,

IndiaPressure-tested VRF joints give our team confidence in quality and support our compliance requirements.

Technical Director, Green Building Specialist,

UKTheir 5.2MPa test certificate with every batch gives us and our clients and us absolute confidence

Owner, Mechanical Contracting Firm,

Saudi ArabiaOur Blogs

FAq's

What makes the TA Series different from standard VRF branch joints?

The TA Series is a complete, pressure-tested system kit. It has an under-the-skin shape that is optimized to an extreme such that the refrigerant flows efficiently, and it already has the best insulation. That is, it will operate at full capacity, there will be no additional delays in installation, and you are assured that it will not leak, which can not be assured by boring untested parts.

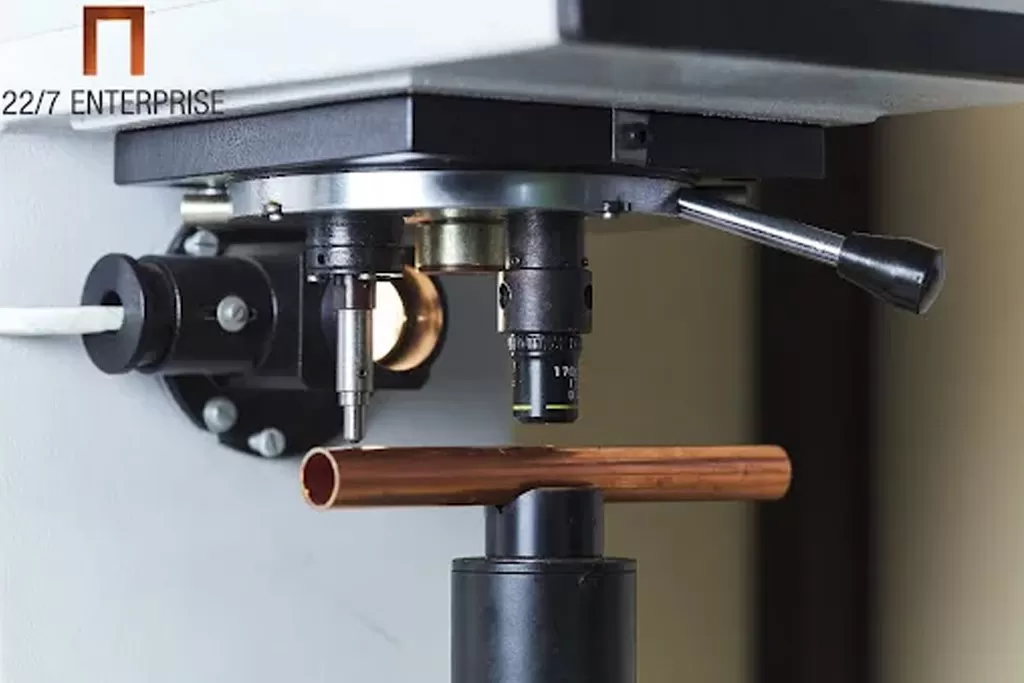

How does the 5.2MPa pressure test benefit my installation?

We examine every joint at 5.2 Mpa, which is far beyond the normal VRF pressure. The fact that hard testing renders the seal 100 per cent leak-proof prevents the most frequent pain points and broad takeaways. It makes it last in the long run, it preserves the compressor and it eliminates expensive repairs and refrigerant leaks post installation.

How does TA Series support faster and more consistent installation quality?

TA Series kits are manufactured to precise dimensions, feature factory-tested joints, and offer optional pre-insulated configurations. These features help contractors maintain uniform installation standards, reduce on-site rework, and support consistent VRF system performance across projects.

Why is in-house silver brazing a critical advantage?

The process is maintained on a high standard through in-house brazing using a 2 per cent silver alloy. It provides joints stronger, more flexible, and resistant to corrosion, much more than normal brazing. The main step that makes the permanent, airtight seal we assure is the assurance of a 100 per cent run and the long-awaited breakdown.

What are the options for insulation, and are they included in the kit?

We offer XLPE for standard use or premium Armaflex Class O Nitrile for superior thermal and moisture resistance. Our premium kits have a pre-insulation, which means the seal is perfect with no holes and reduces the amount of labour on site and maintains the heat flow constant.

How does your design improve overall VRF system efficiency?

Our Y-joints feature an optimized, aerodynamic internal profile. That smoothness interferes with the flow of the refrigerant, reducing much turbulence. Reduced resistance translates to the compressor being easier to operate in order to move the refrigerant, increasing the overall SEER and reducing power bills.

Is it possible to use the TA Series when it comes to cool and heating?

Absolutely. The TA Series is engineered for the full operational scope of VRF technology. It is constructed in the entire VRF range. Hard construction and assured seals withstand the stress and variations in temperature of heat pumps and heat-recovery units to ensure it operates throughout the year.

Do you provide certification or test documentation?

Yes. Each batch includes a Certificate of Conformance. Upon request, we provide individual 5.2MPa pressure test reports. The complete documentation allows you to track all that, supports quality control, and provides the engineers and the owners with the assurance regarding the integrity of the part in the event of vital installs.

What is your minimum order, and how long does it take?

Yes, we are flexible regardless of the size of the project. Reliability is established by setting lead times. Give us your information, and we will provide a valid quote and schedule.

What do I have to do to ensure I order the correct kit?

Consult our technical team. Please provide your system diagram, the size of your branches you require (such as 22.2mmx12.7mm), and insulation preference. We will select the specific TA Series kit that will fit your VRF plan, so you will not screw up or wait.