Variable Refrigerant Flow (VRF) systems represent some of the most efficient and highly developed HVAC solutions that could be currently offered. Initially developed in Japan by Daikin in 1982 as Variable Refrigerant Volume (VRV), today, the systems have gained popularity all around the world. Their greatest advantage is flexibility; they are capable of heating and cooling different areas at the same time, fine-tune refrigerant flow and require little power to operate. With the requirements of building energy codes increasing, and the need to find smarter HVAC solutions, VRF technology has become a clear choice because of its performance, ability to scale and value over time.

Historical Development and Brand Examples

In 1982, Daikin introduced the first VRF system and branded it as VRV system (Variable Refrigerant Volume). In order to clarify to define VRV, VRV should simply be known as the proprietary branding given to Daikin by the HVAC industry in general when discussing VRF, or Variable Refrigerant Flow. Even though VRF vs VRV might seem like rival systems, they are not. VRV is a trademark of the Daikin corporation, but VRF is the default industry designation.

Other brands such as Mitsubishi Electric (City Multi), LG, Toshiba, and Hitachi have made an entry in the market over the years, over their own innovations, though Daikin is the original developer of the VRV air conditioning system with its superior zoning and energy-saving features. All the brands have minor variations in design, software, and controls but operate on the same fundamental principles.

What Is a VRF System?

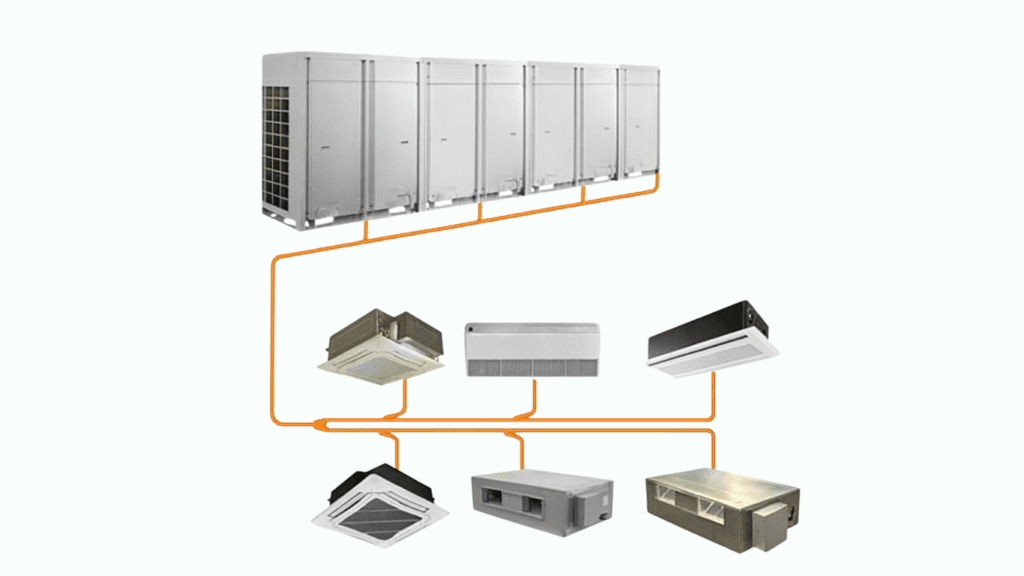

A VRF system is a variation of HVAC solution whereby refrigerant acts as the direct heating and cooling gas. The system is built of an outdoor condenser unit, which is connected to various indoor units via a network of refrigerant pipes. And unlike standard HVAC systems, which cycle on and off, VRF maintains the optimum volume of refrigerant to each indoor unit by utilising inverter-drives on its compressors, and supplying just enough heating or cooling.

The result of such control is greater energy efficiency, less wear on parts, and smoother occupant comfort. The flow of refrigerant is very accurate, and the different indoor units can work independently, so VRF is a very effective technology when buildings have variable thermal loads on different spaces.

Core Components Behind VRF Technology

Outdoor Condensing Unit

This is the system’s epicentre. It includes the use of inverter-driven compressors, which regulate their performance according to the immediate demand. Unlike fixed speed or conventional compressors, inverter technology facilitates smooth operation, energy efficiency and capacity to last longer.

Indoor Units

These units are of various types, wall-mounted, cassette, ducted or suspended to the ceiling. They are operated individually, which means that various rooms or zones can have distinct temperature control.

Branch Selector Box

This is a component found in the VRF heat recovery systems, which allow heating and cooling at the same time, by pushing refrigerant to relevant internal points. It makes the optimal use of energy in the building.

Refrigerant Piping

VRF has no bulky ductwork and, instead, it makes use of copper refrigerant lines, which are simpler to install and fit within tight ceilings or retrofit applications. These are the pipes that are used to connect the outer unit to all inner units, and they have VRF refrigerant joints that are used to assure an effective flow and prevent leakages.

How Does a VRF System Work?

Fundamentally, a VRF system operates by detecting the thermal demands of each Zone and tailoring the refrigerant flow in response. Here’s how:

➲ The inside units incorporate temperature, humidity and occupancy sensors.

➲ The inverter compressors installed on the outdoor unit effectively maintain the desired output, furnishing exactly the needed amount of refrigerant.

➲ A VRF (Variable Refrigerant Flow) system is a smart way to distribute refrigerant to indoor units and provide different capacities of units based on real-time cooling and heating demands in each zone.

➲ Within heat-recovery applications, a branch selector box channels expelled heat from a cooling zone (e.g., a room being cooled) to a heating zone in need, thereby enhancing overall efficiency.

This innovative operation cuts energy costs and delivers uniform comfort in every zone.

Types of VRF Systems

VRF Heat Pump

A VRF Heat Pump is a system that enables each of its indoor units to be either heated or cooled, but not both, at the same time. It is suitable in open offices, classrooms, or areas of even temperature requirements. It has a two pipe system that makes it simple and inexpensive to install.

VRF Heat Recovery

A more developed variant, the VRF system of heat recovery, can simultaneously provide heating and cooling of various areas. This is facilitated by a heat pump system of recovery, which sends the refrigerant strategically through selector boxes of branches. Hotels, buildings with many tenants, and places with competing temperature preferences are ideal.

Air-Cooled vs Water-Cooled

VRF systems are air-cooled (the most common) or water-cooled (where centralised cooling towers are used in bustling tall buildings). Water cooling systems are effective in medium and large building applications with limited external air flow.

Advantages of VRF Systems

➲ Energy Efficiency: VRF systems can minimise energy consumption by 30-55 per cent as opposed to conventional HVAC units. Energy that is wasted is reduced by using heat recovery and constant compressor speed modulation.

➲ Zoned Comfort: Every zone or room has an individual thermostat and each room can be cooled or heated separately.

➲ Quiet Operation: VRF gives fewer start-stops and quieter internal units and so is excellent in libraries, hospitals, and high-end homes.

➲ Space Saving: Large ductwork is lacking and, due to the use of compact VRF units, installation is simplified and more space-saving.

➲ Smart Controls: Most contemporary systems are eligible to be implemented in Building Management Systems (BMS) and to be monitored through mobile applications in real-time.

Limitations to Consider

➲ High Initial Cost: The cost of equipment and installation is increased compared to the conventional HVAC and particularly the multi-split air conditioners.

➲ Complex Design and Installation: VRF needs the proper design, calculated load and skilled technicians to operate efficiently.

➲ Limited Fresh Air Handling: VRF systems cannot normally be used on their own, and often must be used with other independent fresh air systems.

Applications of VRF Systems

➲ Corporate Offices: Allows set-point flexibility floor-by-floor and department to department.

➲ Hotels: VRF air conditioning system offers individual control of each room independently without disturbing the others, giving each guest their desired comfort.

➲ Hospitals: Demands silent, clean, and stable climate conditioning.

➲ Educational Institutions: It is possible to condition zones such as classrooms, labs, and libraries, depending on use.

➲ Residential Complexes: Luxury apartments and villas experience accurate climatic control without compromising style.

Conclusion

The VRF system is not just one of the HVAC system options but a scalable system that ensures a smart HVAC system that suits modern buildings. Its capability to provide comfort that is tailored to the needs of tenants and lower utility costs, as well as respond to a variable load, makes it a suitable option in various commercial and residential projects. Whether it is in a facility upgrade or facility design, the implementation of variable refrigerant flow VRF systems can offer long-term functionality with short-term ROI. VRF will serve as the foundation of future-proof climate control as technologies such as IoT and AI enter the HVAC market.

FAQs

What is the energy efficiency of a VRF system, in comparison to conventional HVAC?

The main advantage of VRF systems being so energy efficient compared to traditional HVAC systems is the ability to control how much refrigerant it is circulating to the distributing unit in order to fulfil the demand in real-time. Rather than cycling on and off, as traditional systems do, VRF compressors are driven using inverters, which allow them to rise and fall in speed according to their load, eliminating energy spikes and better matching the load. VRF systems also reduce duct losses, and have the ability to zone individually, thus preventing over-conditioning of unoccupied areas. There are also heat recovery models that increase efficiency by circulating waste heat among zones. Research shows that VRF systems have the potential to deliver 30-55 per cent energy savings, which makes it an intelligent long-term investment option to energy-efficiency conscious building owners.

What is the difference between VRF and HVAC?

HVAC in its general application can take into account any heating, ventilation and air-conditioning system, whether chillers, packaged systems, ducted systems or split ACs. VRF in comparison, is a subset of HVAC that depends on variable-speed compressors and refrigerant pipes instead of ducts to control temperature. The main difference is that VRF supports zoning, where different rooms may be set at different temperatures, whereas standard HVAC systems usually push a common temperature to a whole building. VRF solutions are more energy efficient, offer the retrofit applicability quicker than conventional air-source technologies on the one hand, and are more costly upfront and need special expertise as far as installation, maintenance on the other.

What is VRF and why is it used?

VRF, or Variable Refrigerant Flow, is a climate control system which constantly adjusts the flow of refrigerant between one outdoor unit and a multiplicity of indoor units. It finds its application in systems that require accurate temperature control, good energy performance, and flexibility of single-zone/multi-zone applications. Its inner units are autonomous, and people in different rooms can adjust the temperature to warm or cool. VRF systems have found application in commercial buildings, in luxury apartments and hotels due to their inverter-driven compressors that use less energy and, in advanced versions, produce both heating and cooling at once. They are also more compact and less noisy compared to traditional HVAC systems and promote occupant comfort and aesthetics.

Is VRF better than split AC?

Yes, VRF is usually superior to the conventional split air conditioners, particularly in medium to large buildings. Although split ACs work in disjointed zones, have one outside unit per inner unit, VRF involves linking various indoor units to only one outside unit, minimising external clutter and enhancing aesthetics. VRF systems also employ inverter technology to exactly align cooling/heating loads, which provides great energy savings in the long run. They are also supportive of zoned climate control and can incorporate heat recovery, whereby one room is cooled but the other heated. VRF systems are costly but long-term efficient and flexible.

What is the principle of VRF?

VRF working principle is to modify the quantity of the refrigerant sent to each indoor unit depending on the demand. It operates on inverter-controlled compressors which adjust the flow of air to suit the exact cooling or heating needs of different zones. With this modulation, the inefficiency of the on/off compressor cycle is eliminated. The indoor unit has a sensor and electronic expansion valves that assist in regulating flow of refrigerant. VRF is so efficient that in heat recovery systems, it is possible to transfer heat across zones as well. It is through this smart refrigerant control that VRF systems can obtain better performance and energy savings.

What is the VRF formula?

VRF does not have a specific formula such as a mathematical equation, but HVAC engineers use conventions when calculating, even during system design. These are cooling load and heating load estimates (in BTUs or kW), diversity factors, interior unit capacities, and pipe sizes. Manufacturers such as Daikin, LG and Mitsubishi have software tools to determine these values, depending on building layout, insulation, occupancy and usage patterns. The diversity aspect is also important since not all zones demand filled capacity at the same time. Coefficient of Performance (COP) and Energy Efficiency Ratio (EER) tips can be used by engineers in performance evaluations to measure the efficiency of various systems and their recovery potential.