Introduction

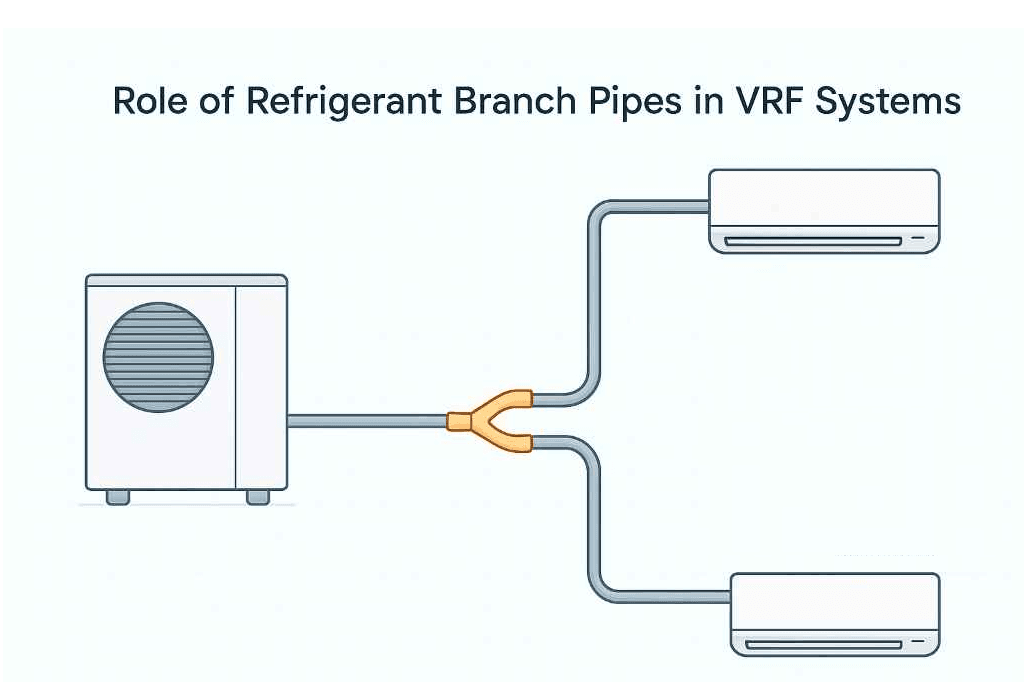

Variable Refrigerant Flow technology is a zoning, adaptive high-efficiency HVAC system in the new world of heating and cooling. However, to get a complete grasp of such systems, it is important to delve into the Role of Refrigerant Branch Pipes, the unseen arteries that work to pipe the refrigerant accurately though numerous zones. These branch pipes are not merely pipes, they are essential control devices that allow zoned comfort, efficient energy consumption and stability of the system over the life of the building.

What Are Refrigerant Branch Pipes?

Refrigerant branch pipes are special copper pipe assemblies utilized in VRF systems to branch and divide the refrigerant flow between the outdoor unit to several indoor units. These are designed to give a balanced flow, low pressure loss, and smooth performance over the range of loads. These pipes, whether cooling or heating, are dependable to a delicate balance between the refrigerant liquid and gas phases.

Branch pipes are mostly used with other parts such as refrigerant copper fittings, which are used to connect and stabilize the joints between the branches and main lines. Such fittings are necessary so as to avoid leakages and to make the system last longer.

Key Roles in VRF Systems

Distribution & Equalization of Refrigerant Flow

Branch piping is key in the equal distribution of refrigerant to various sections of a building. The right amount of refrigerant is supplied to each indoor unit depending on its need thereby, facilitating individual temperature control. VRF systems are particularly dependent on this kind of accuracy to provide its zoning benefits.

Enabling Simultaneous Heating & Cooling

The advanced VRF systems can provide heating and cooling in separate areas at the same time. It is made possible by an intricate design of vrf refjoint manufactures that directs refrigerant in a strategic manner. Such flexibility, without efficient branch piping, would be difficult, both mechanically and thermodynamically.

Pressure & Oil Management

Ensuring pressure balance and correct oil back to the compressor is critical to the long life of VRF systems. The branch pipes are pitched and designed in such a manner as to encourage oil flow back to the outdoor unit, particularly with longer pipe runs and multi-story applications.

Energy Efficiency & Load Matching

The VRF systems save energy greatly subject to proper load matching. When the branch pipes are sized and installed correctly, the system will dynamically react to the indoor needs, minimizing over-cooling/over-heating and resulting in reduced total energy use.

Types of Branch Pipe Configurations

Y-Branch/Refnet Joints

The Y-branch, which is also known as Y joint copper pipe, is the most utilized branching component in VRF systems. This Y-shaped design divides the refrigerant flow without excessive turbulence and is typically fabricated in a factory to ensure a high degree of precision and integrity of the brazing. When VRF Y joint installation, brazing and insulation processes should be per the manufacturers recommendations in order to avoid refrigerant leakage and thermal losses.

Separation Tubes & Multi-Port Headers

In systems of larger capacity or more complicated zoning, multi-port headers or separation tubes are employed. These give several outlets off of one main line, which eases layout and minimizes the use of multiple Y-joints.

Materials, Standards & Manufacturing

Branch pipes are normally made of high quality copper in order to sustain pressure and temperature changes with time. VRF Refnet Joint is one of the most important products in the market that is pre-insulated and easily installed. These joints are precision made to very close tolerances and give a positive, leak free system when correctly brazed and tested.

The reputed brands in refrigerant copper fittings manufacturers insist on the use of ASTM B280-grade copper to ensure consistent wall thickness, resistance to corrosion, and tensile strength. The efficiency of such a system and its life cycle depend directly on the quality of these materials.

Installation Best Practices

The quality of joints, contamination, or incorrect piping size are some of the most widespread improper installation causes of VRF system failure, which can be tracked down to poor joint quality, contamination, or wrong piping size. This highlights the importance of following the best practices in installation.

Dry, Clean & Tight Principles

The foundation block of any refrigerant piping system is the DCT principle- Dry, Clean, and Tight. Refrigerants hate moisture; they combine with oil to create acids that eat away internal parts. When brazing, all pipes and fittings should be purged with nitrogen to prevent inside oxidation.

Besides, ends must be capped as soon as cutting is done to avoid the ingress of dust and debris. Deburring must be performed carefully to avoid copper shavings which may destroy expansion valves or compressors.

Proper Sloping, Supports & Insulation

Pipe arrangement should be sloped at about 1/4 inch every 10 feet (2%) back towards the outdoor unit to allow oil to flow back. Oil traps in riser section may be necessary every 20 feet of vertical lift.

To prevent the sagging and possible rupture of the pipes, they are to be supported with cushion clamps every 4 6 ft. All uncovered places should be covered with closed-cell insulation to avoid condensation, particularly in warm and damp climates.

Every Refnet joint price can indicate degree of pre-insulation and material grade, which cannot only affect the first cost, but also long-term energy savings and installability.

Leak-Free Joints & Brazing Quality

It must be properly brazed with silver alloy rods and a continual purge of nitrogen. This guarantees that the internal surfaces of the pipes do not oxidize and that the joint is clean. Every joint should be visually examined and hydrostatically tested with dry nitrogen to a maximum of 500 psi.

Vacuuming to less than 500 microns is required after pressure testing to remove non-condensables. There are system commissioning checklist requirements where technicians have to log vacuum hold time and pressure rise data.

Mechanical Alternatives (ZoomLock, LokRing)

Mechanical press fittings, such as ZoomLOCK, provide flame free installation, making them suitable in hospitals, data centres and retrofits. Speedy installation (up to 50 percent faster) tools require more expense than conventional brazed fittings.

They are catching on in markets where there is a shortage of labor, or where fire safety regulations are tighter. Their long-term reliability in VRF systems is, however, still controversial, and they should be purchased only from certified VRF joints manufacturers to guarantee their compatibility with the system.

Sizing & Selection Considerations

The design of branch piping cannot be reduced to physical connections only- it is an engineering task, which involves complex calculations and needs to consider the manufacturer guidelines. A failure to size correctly may result in ineffective performance, system failure, and investment waste.

Pipe Diameter, Length & Pressure Drop

Adequate sizing keeps the velocity of the refrigerant within acceptable limits, which limit noise, avoid oil traps and limit pressure drops. Whereas, too small pipe will cause high friction and pressure loss. Too large and it will lead to refrigerant pooling and oil separation.

VRF manufacturer guidelines or software tools which take into account load, elevation difference, refrigerant type, and total equivalent pipe length are consulted by the engineers. Velocity requirements at branch joints and elbows must be given special attention to prevent turbulence.

Poor layout may also cause flash gas, i.e. liquid refrigerant may evaporate prematurely, causing inadequate cooling at the indoor units and increased compressor load.

Matching Indoor Load with Branch Sizes

Branch pipes sizing should be adjusted to the total capacity of the indoor units connected. As an illustration, a 5-ton outdoor unit with three 1.5-ton and one 0.5-ton indoor units would need a consideration of Refnet joint sizes as well as their sequence.

Manufactures offer branch selection charts, which specifies the inlet and outlet diameters needed in each configuration. With these charts, oil return will be well supported too, particularly in a system where some indoor units are not operating, but others are.

Preventing Leaks & Fault Diagnosis

A small leak of the refrigerant can greatly impact performance and safety of VRF system. Design integrity and subsequent routine maintenances are the starting points of identifying and preventing these faults.

High-Quality Components & Pressure Testing

It would aid in achieving quality assurance when using parts of certified VRF joints manufacturers. Such manufacturers perform a great deal of test work, such as helium leak testing, dimensional inspection, and burst strength testing.

After the system is installed, the system is pressure tested with dry nitrogen to 500-600 psi and this is maintained constant over a 24 hour period. Leak-free installation is verified by a steady pressure indication. This is then followed by a thorough vacuuming to get rid of the non condensables which is very vital to system performance.

Leak excitations are commonly pursued to inadequate brazing, polluted fittings, or excessive tightening of mechanical joints. Torque wrenches and brazing schedules are methods that minimize these risks.

Scheduled Maintenance & Leak Detection

Newer systems have refrigerant sensors and pressure gauges that warn the user of an unusual loss of refrigerant charge. Routine maintenance in commercial environments should comprise electronic leak detection, visual inspection of insulation, and thermal imaging to identify cold spots.

Maintenance personnel can be instructed to look out of indicators such as frost formation, compressor short-cycling, or odd power consumption spikes which can be warning signs of branch piping problems.

Proper commissioning and preventive maintenance will pay off by avoiding performance lulls as well as avoiding nullification of warranty terms by carelessness.

Conclusion

With increasing regulations on energy usage and buildings striving to become Net Zero compliant, the popularity of VRF systems rises because of their zoning ability and efficiency. Nevertheless, the piping infrastructure can be imperfect, and even the most advanced VRF equipment will not be able to perform well.

The key to any successful HVAC installation is a correctly designed VRF refrigerant branch piping. Whether in the early stages of planning or long-term maintenance, each choice, every component specified and insulation detail matters.

Although contractors might be tempted to save on cost by compromising on the quality of branch piping of VRF systems, the branch piping system is a critical component which must be invested in to ensure reliability, efficiency and occupant satisfaction.

FAQs:

1. What is Refrigerant Branch Pipes?

Variable Refrigerant Flow (VRF) systems utilize special copper pipe called refrigerant branch pipes to divide and branch the flow of refrigerant in a single main line to numerous indoor units. With these pipes, refrigerant can be delivered in a precise manner according to the cooling or heating requirement of each zone. Branch pipes are used to provide stable refrigerant pressure, flow rate, and phase (liquid or gas) at all terminals connected. Modern HVAC systems cannot be energy efficient, flexible in zoning or perform at an optimal level without them, particularly where multi-room or multi-floor commercial installations are involved.

2. What type of pipe is used for refrigerant?

The most intended material used in refrigerant lines in HVAC and VRF is copper pipe, as the copper has good thermal conductivity, resistance to corrosion, and high-pressure durability. Type L and Type ACR (Air Conditioning and Refrigeration) copper tubing are the two most common types. ACR tubing is produced specifically to be used in HVAC systems- the tubing is already clean, dehydrated, and capped to avoid contamination. Such pipes should be compatible with ASTM standards including B280 which ensures reliability in performance. Aluminum or steel can sometimes be used in commercial applications, however copper is the industry standard in refrigerant piping.

3. How is refrigerant pipe measured?

Instead of measuring refrigerant piping by inside diameter (ID), it is measured by outside diameter (OD), a difference that distinguishes it but not plumbing pipes. The most common sizes are 1/4 inch to 1-5/8 inches OD, but this varies with the capacity of the HVAC system and the type of refrigerant. Manufactures of VRF systems commonly have precisely sizing charts available depending on equipment load, length of pipe, and complexity of the layout. Also, installers should consider equivalent lengths, which consist of elbows and fittings, as they increase resistance to flow. Such correct sizing is essential so that the velocity of the refrigerant remains within the ideal range and avoids the problem of oil returning to the compressor, pressure drop, and lower cooling capacity.

4. How do you test refrigerant piping?

Before charging a system with refrigerant, a series of steps is used to test the refrigerant piping to verify that it is leak-tight and that the system is safe. Leaks are checked by pressure-testing the system with dry nitrogen to 400-600 psi and soaking it overnight. All joints are examined with a soap solution or electronic detector. Once pressure stability has been established the system is vacuum tested with a micron gauge to dry the system and eliminate non-condensables, a vacuum of less than 500 microns is desired. Refrigerant is added only after both pressure and vacuum tests have been passed. Such a procedure guarantees a durability in performance and reliability.

5. What is the thickness of refrigerant pipe?

Refrigerant piping thickness is a factor of the type and diameter. In Type L copper tubing, which is typical in refrigerant systems, the wall thickness is about 0.030 inches (0.76 mm) in small sizes (such as 1/4 inch) and about 0.095 inches (2.41 mm) in large sizes (such as 1-5/8 inch). Cleaned and sealed HVAC copper tubing, ACR, tends to follow these dimensions. The thickness needed would make the pipe resistant to high pressures exerted by refrigerants such as R-410A. When choosing the pipe to ensure system safety and conformity with ASTM B280 standards, it is always recommended to refer to the manufacturer standards as well.