Headers

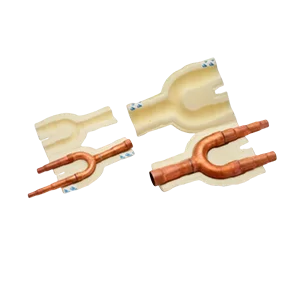

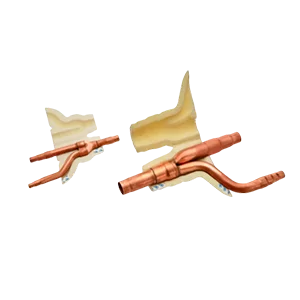

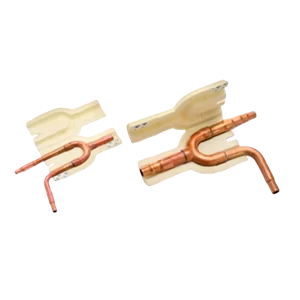

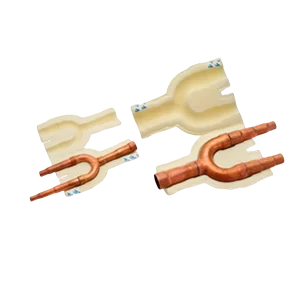

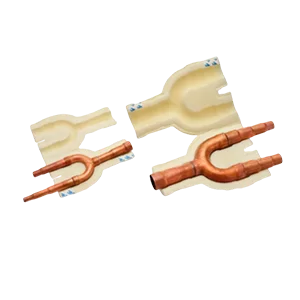

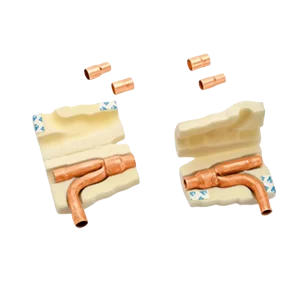

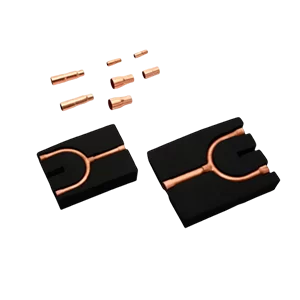

Customized insulation

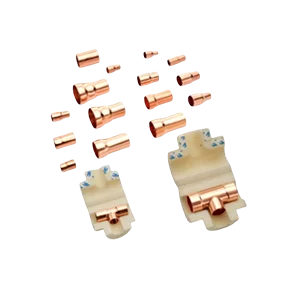

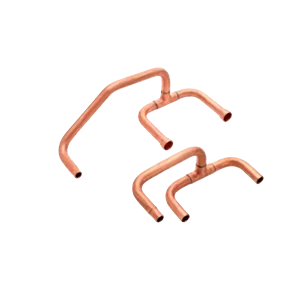

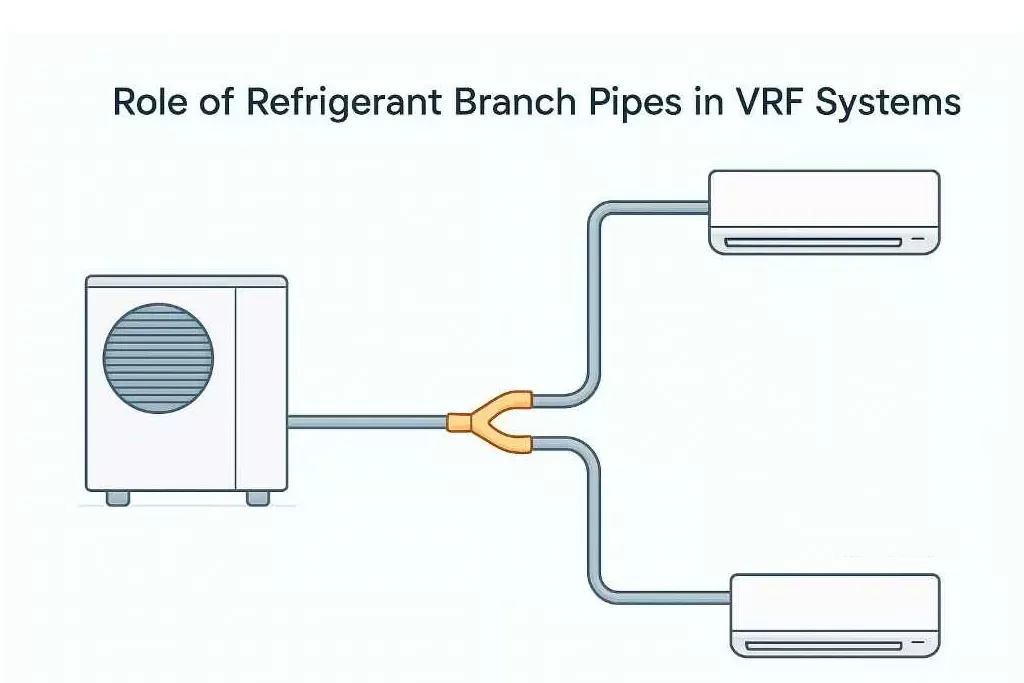

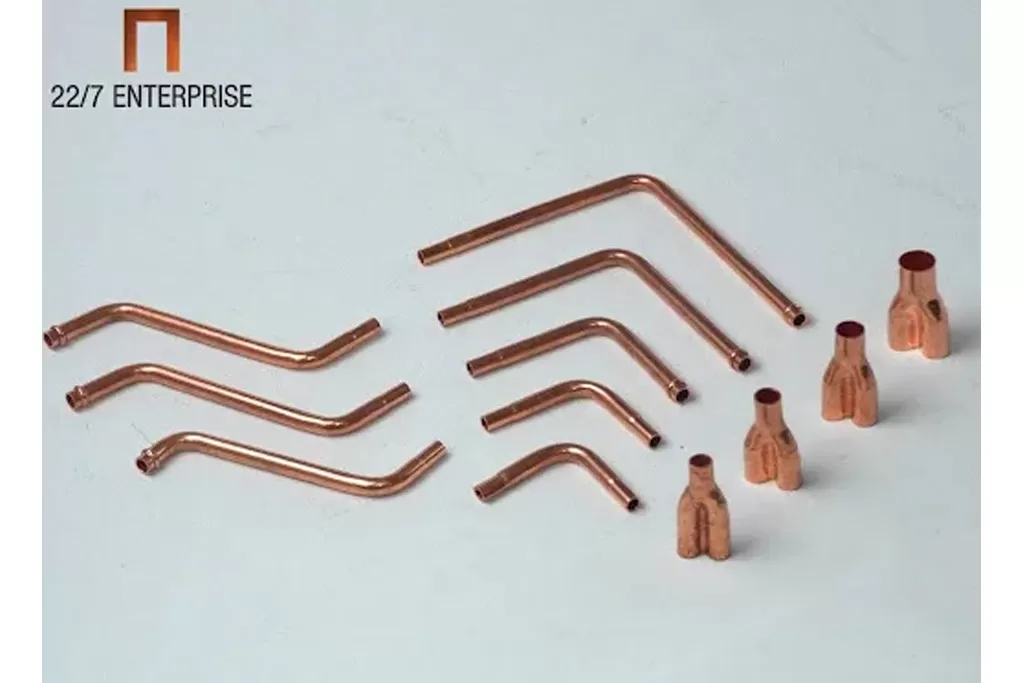

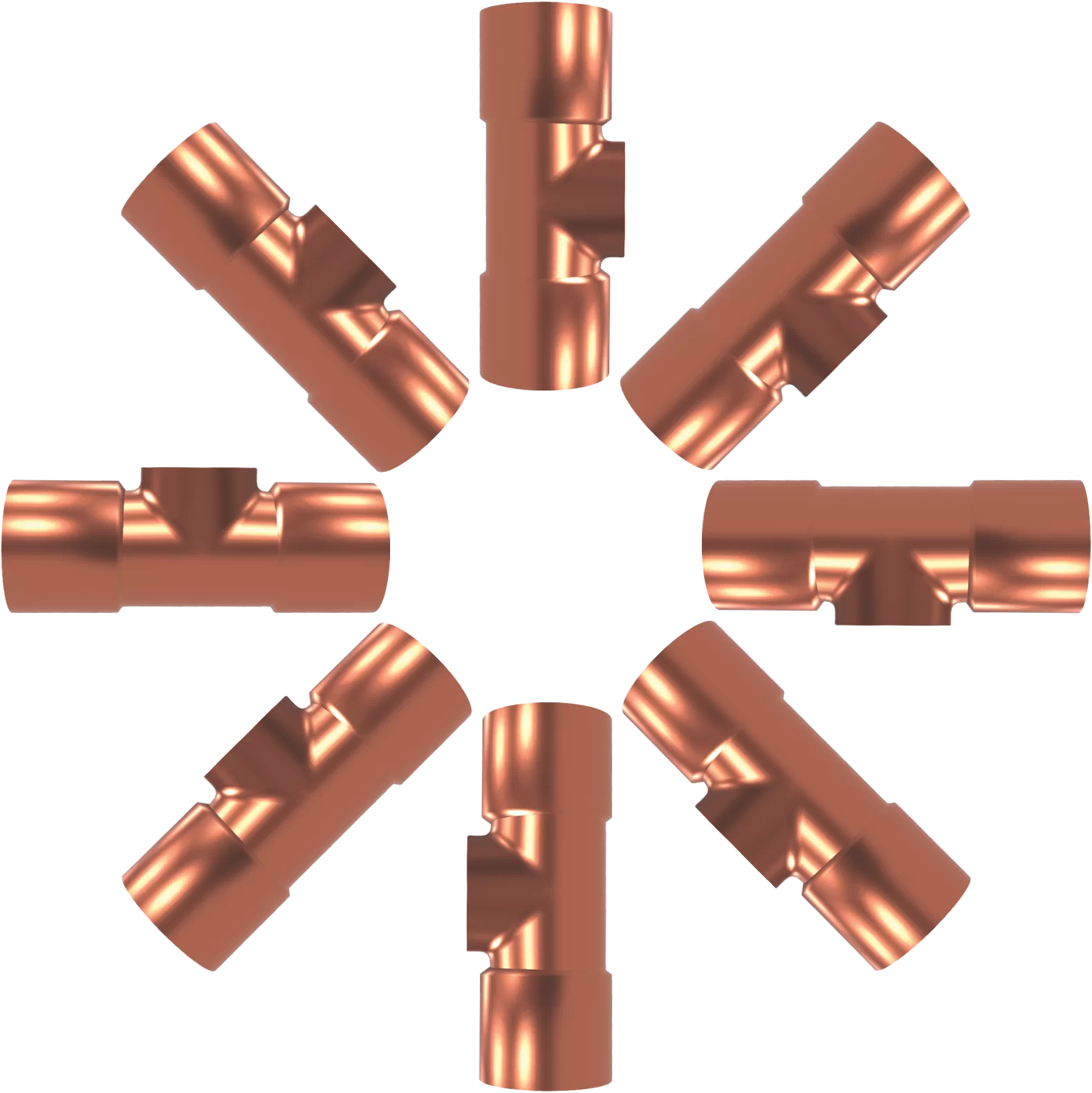

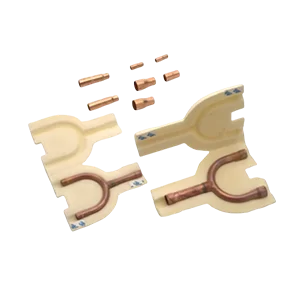

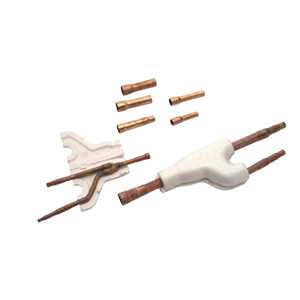

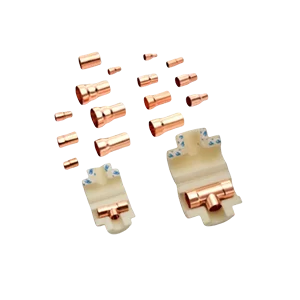

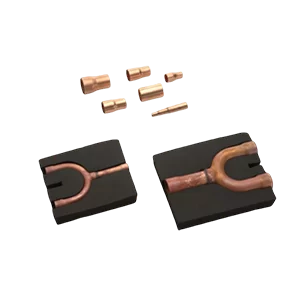

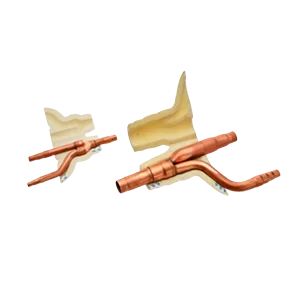

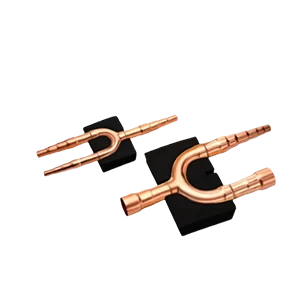

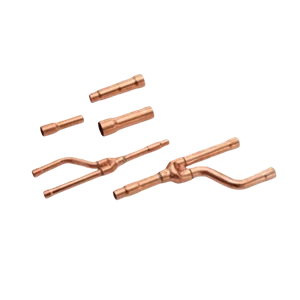

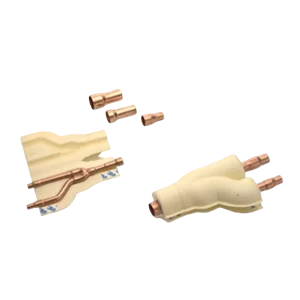

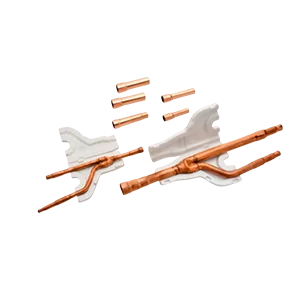

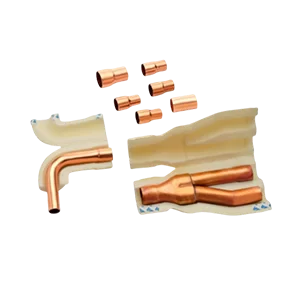

We manufactures ME Series Branch Pipes for dependable VRF installations, connecting multiple indoor units to a single outdoor system. Supplied with copper T-joints, reducers, & insulation, they allow faster fitting with minimal brazing. The design maintains balanced refrigerant flow, tight leak-resistant joints, & consistent long-term operating efficiency.

To improve energy efficiency and control condensation, 227 Enterprise Pvt. Ltd. supplies the ME Series Branch Pipe with XLPE and NBR insulation options. These materials prevent sweating around VRF refrigerant separation tubes, maintaining thermal balance and clean finishes. The ME Series remains a preferred choice for VRF professionals and OEMs.

ME

Series

FEATURES OF ME SERIES

Ease of Installation

Leak Proof Construction

RoHS & CE Compliant

Precisely Designed Joint Geometry

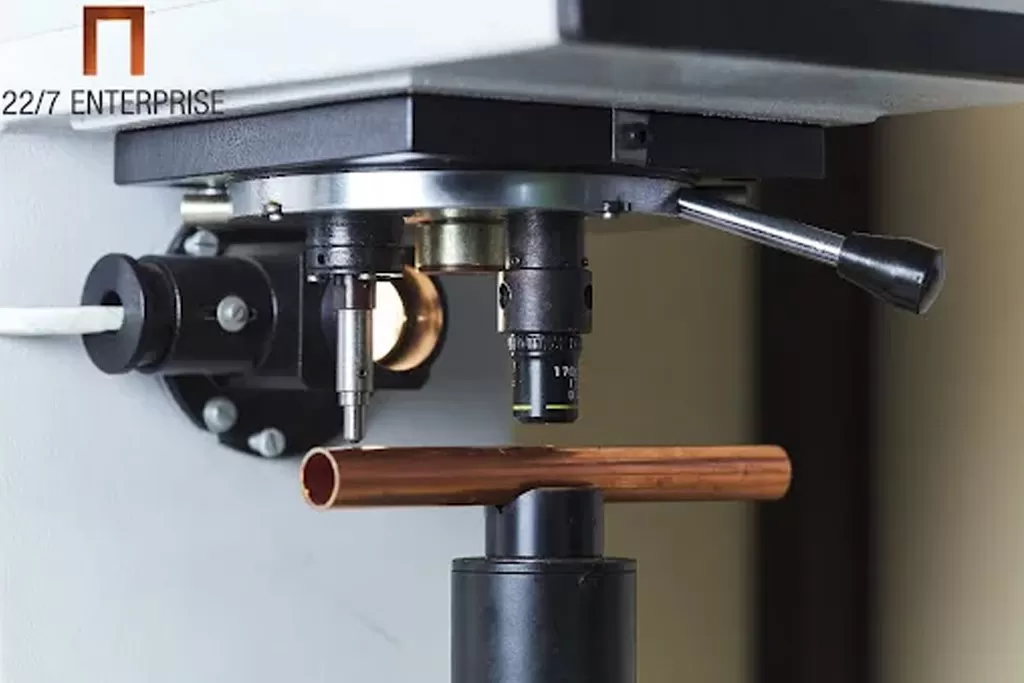

Pressure Tested at 5.2 MPa

Product specification

| Model | Pipe | Pipe A (ID) | Pipe B (ID) | Pipe (ID) | Reducers Number & Qty |

|---|---|---|---|---|---|

| Pi-CMY-Y102SS-G2 | Gas Side | 15.88 (5/8) | 19.05 (3/4) | 19.05 (3/4) | 1 x 1 Nos, 2 x 1 Nos, 3 x 1 Nos |

| Liquid Side | 9.52 (3/8) | 9.52 (3/8) | 9.52 (3/8) | 4 x 2 Nos | |

| Pi-CMY-Y102LS-G2 | Gas Side | 19.05 (3/4) | 25.4 (1) | 25.4 (1) | 2 x 1 Nos, 5 x 2 Nos, 3 x 1 Nos, 6 x 2 Nos, 9 x 1 Nos, 7 x 1 Nos, 8 x 2 Nos |

| Liquid Side | 9.52 (3/8) | 12.70 (1/2) | 12.70 (1/2) | 4 x 1 Nos, 10 x 2 Nos | |

| Pi-CMY-Y202S-G2 | Gas Side | 19.05 (3/4) | 25.4 (1) | 25.4 (1) | 2 x 1 Nos 3 x 1 Nos, 9 x 1 Nos, 10 x 1 Nos |

| Liquid Side | 12.70 (1/2) | 15.88 (5/8) | 15.88 (5/8) | 1 x 1 Nos, 13 x 1 Nos, 10 x 1 Nos, 12 x 1 Nos | |

| Pi-CMY-Y302S-G2 | Gas Side | 25.4 (1) | 31.75 (1-1/4) | 31.75 (1-1/4) | 5 x 1 Nos, 14 x 1 Nos, 15 x 2 Nos, 7 x 1 Nos, 8 x 1 Nos, 16 x 2 Nos, 6 x 1 Nos |

| Liquid Side | 15.88 (5/8) | 19.05 (3/4) | 19.05 (3/4) | 1 x 1 Nos, 13 x 1 Nos, 3 x 1 Nos, 2 x 1 Nos, 18 x 1 Nos | |

| Pi-CMY-Y62-GE | Gas Side | 15.88 (5/8) | 19.05 (3/4) | 19.05 (3/4) | 1 x 1 Nos, 2 x 2 Nos, 3 x 1 Nos, 9 x 2 Nos, 20 x 1 Nos |

| Liquid Side | 9.52 (3/8) | 9.52 (3/8) | 9.52 (3/8) | 4 x 2 Nos, 19 x 2 Nos |

Reducer Number & size

| 1 | OD 15.88 (5/8) – 12.70 (1/2) | 11 | OD 19.05 (3/4) – 25.4 (1) |

| 2 | OD 19.05 (3/4) – 15.88 (5/8) | 12 | OD 12.70 (1/2) -6.35 (1/4) |

| 3 | OD 19.05 (3/4) – 12.70 (1/2) | 13 | OD 15.88 (5/8) – 9.52 (3/8) |

| 4 | OD 9.52 (3/8) – 6.35 (1/4) | 14 | OD 25.4 (1) 12.70 (1/2) |

| 5 | OD 25.4 (1) -28.58 (1-1/8) | 15 | OD 31.75 (1-1/4) – 34.93 (1-3/8) |

| 6 | OD 25.4 (1) – 19.05 (3/4) | 16 | OD 31.75 (1-1/4) – 41.28 (1-5/8) |

| 7 | OD 25.4 (1) – 15.88 (5/8) | 17 | OD 31.75 (1-1/4) – 28.58 (1-1/8) |

| 8 | OD 25.4 (1)-22.22 (7/8) | 18 | OD 15.88 (5/8) – 6.35 (1/4) |

| 9 | OD 19.05 (3/4) – 22.22 (7/8) | 19 | OD 9.52 (3/8) – 12.70 (1/2) |

| 10 | OD 12.70 (1/2) – 9.52 (3/8) | 20 | OD 15.88 (5/8) – 19.05 (3/4) |

OUR Products

Universal

Branch Pipe

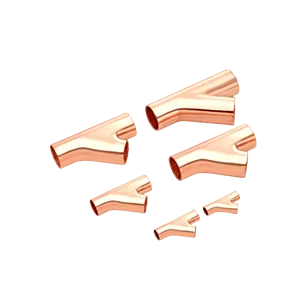

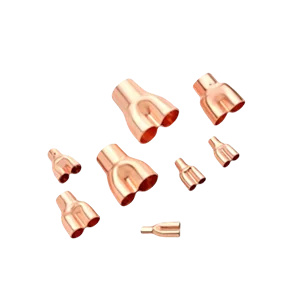

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

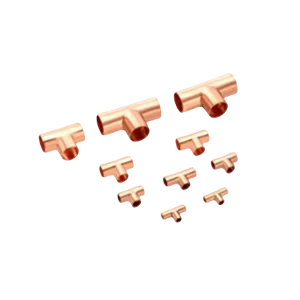

ME

Series

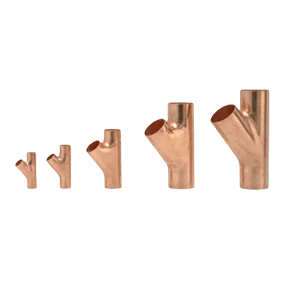

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

AX

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

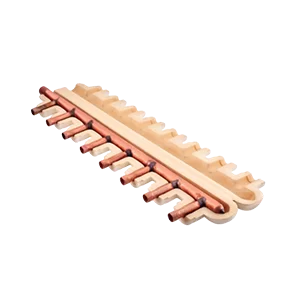

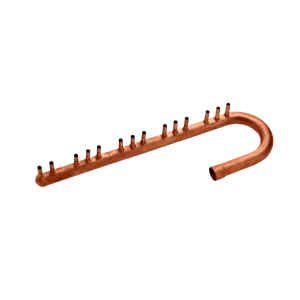

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

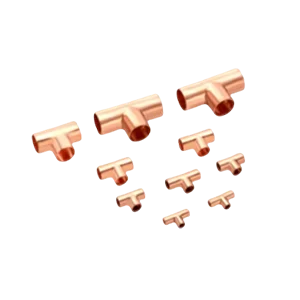

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

Switching to 227's pre-assembled ME Series kits cut our VRF piping installation time by 30%, a game-changer for project scheduling.

Project Director, Large-Scale Commercial Developer,

UAEThe precision of these fittings is outstanding. We've seen a noticeable reduction in callbacks for leak checks since we standardized on their joints.

Service Manager, HVAC Contracting Firm,

IndiaAs an MEP consultant, specifying 227 Enterprise gives me confidence in the system's longevity and performance, which I can confidently guarantee to my clients.

Lead MEP Consultant, International Design Firm,

Saudi ArabiaTheir OEM-level quality at competitive pricing has made them our sole supplier for refrigerant piping components across all our projects.

Procurement Head, Hotel Chain Group,

QatarThe technical support and documentation provided ensured a smooth installation for a complex retrofit project, minimizing on-site challenges.

Facilities Engineer, Healthcare Group,

OmanOur Blogs

FAq's

What is the ME Series, and what does it include?

The ME Series is a pre-engineered refrigerant branch piping kit for VRF systems. Each kit includes precisely matched liquid and suction copper tee joints and all necessary reducer connectors, designed for easy, leak-proof installation with R410A refrigerant

Are ME Series joints compatible with my existing VRF system?

Yes, the ME Series is built to work smoothly with all leading VRF brands that use R410A refrigerant. Each kit is manufactured to the same precise dimensions and specifications, so it fits easily into the system and connects without any hassle.

How do your joints ensure a leak-proof connection?

Every single ME Series joint is individually pressure tested at 5.2 MPa (over 750 psi) before shipment. Combined with precision-machined surfaces and the use of high-quality brazing alloys, this guarantees a perfect, durable seal

What are the benefits of using your pre-assembled kits over sourcing separate parts?

Our kits are put together to make installation more straightforward and to take the uncertainty out of the process. Since the components are already matched to each other, there’s far less cutting and brazing to be done at the site. That not only saves time but also reduces the chances of contamination, while helping the refrigerant flow stay properly balanced right from the start.

What insulation options are available, and why does it matter?

We provide insulation options in both XPLE and NBR Armaflex to suit different project needs. Good insulation plays a much bigger role than people often realise, it stops the pipes from sweating and forming condensation, helps retain the refrigerant temperature, and cuts down on unnecessary energy loss. Just as importantly, it protects ceilings, walls, and other interior finishes from moisture damage over time.

Are these products certified for international projects?

Absolutely. The ME Series is ROHS and CE compliant, meeting stringent international safety and environmental standards. This makes them suitable for export and use in regulated projects worldwide without compliance concerns.

Why choose copper over other materials for VRF joints?

Copper offers unmatched durability, superior corrosion resistance, and excellent thermal conductivity. It is a 99.9% pure, lead-free material that ensures system longevity, safety, and long-term reliability, making it the industry standard for critical refrigerant lines

How does using your product impact overall VRF system efficiency?

Precisely balanced refrigerant flow is key to VRF efficiency. Our joints are engineered for precise distribution, preventing uneven cooling and heating, as well as reducing compressor strain. This helps maintain the system's designed SEER rating and optimal energy consumption

Can you provide custom configurations for unique project requirements?

As a top-tier manufacturer, we specialize in customized solutions. We can engineer ME Series kits to meet non-standard sizes or specific project configurations. Contact our technical team with your project schematics for a tailored quote.

What is your lead time, and do you offer volume discounts?

We maintain stock for standard kits for quick dispatch. For large project volumes and custom orders, we offer competitive tiered pricing. Please reach out via the contact form for a specific quote based on your quantity and delivery timeline.