Manufacturer of Premium Customized VRF &

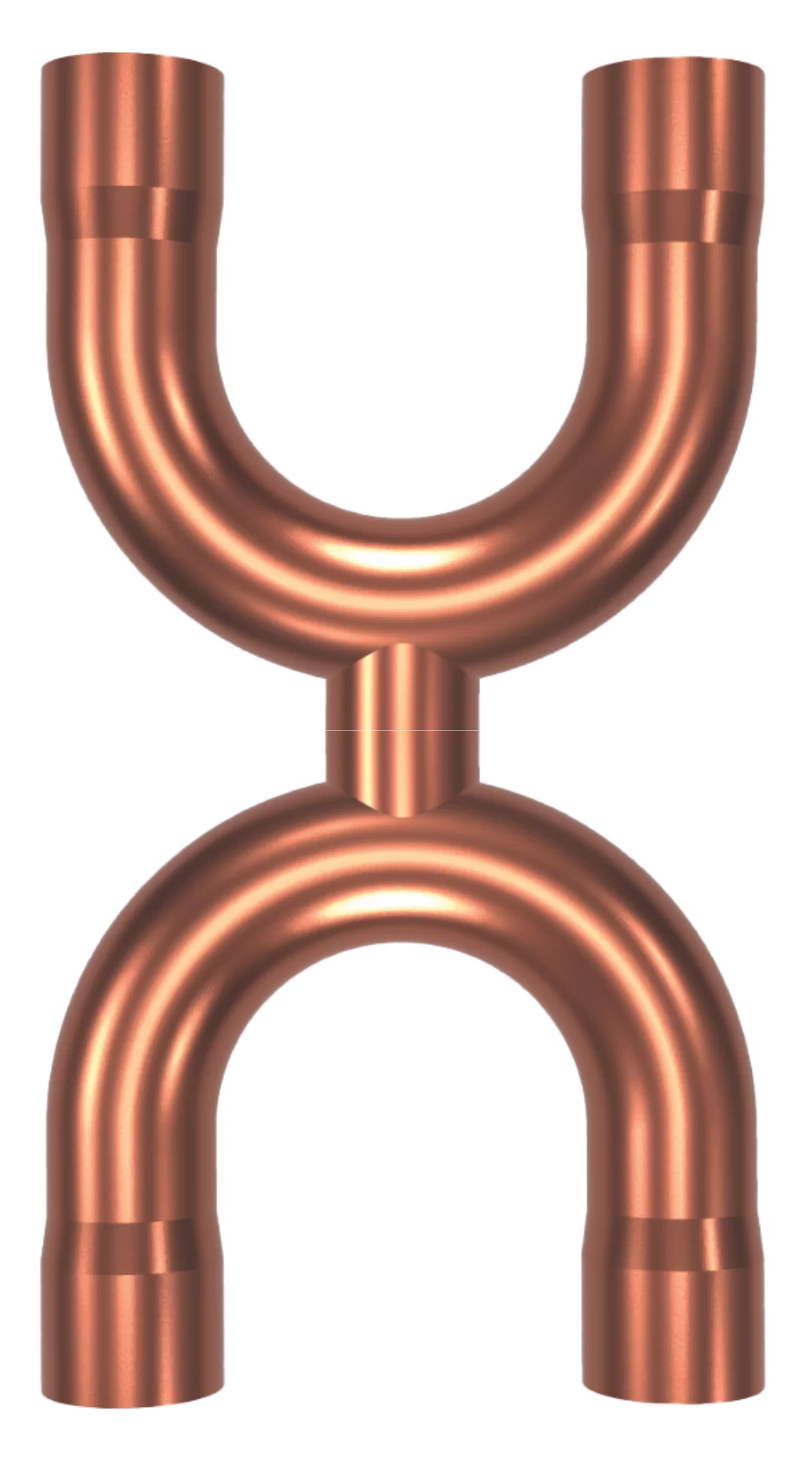

Refnet Joints, Copper Branch Piping Kits,

Fittings, Components, Refrigerant Pipes and Accessories.

We believe in adding value for every stakeholder: clients, vendors, employees, and partners.

Our core philosophy is a commitment to consistently deliver

highest quality, ensuring value in every product.

PRECISION ENGINEERING DEFINES OUR CORE VALUE.

Our corporate philosophy adds value to all stakeholders—buyers, vendors, employees, and partners. As a premier VRF Joint and Copper Components Manufacturer, we commit to exceptional value by consistently delivering the best quality for system longevity and peak performance.

RESEARCH AND DEVELOPMENT

From raw material inspection through precision

brazing to final pressure testing, 227 ENTERPRISE employs

specialized machines and advanced tooling. Our meticulous

processes ensure flawless product quality and reliability, enabling trouble-free,

long-lasting performance and seamless integration

for OEM applications.

WHY BUY FROM US?

All products are 100% pressure tested at 5.2 MPa for guaranteed reliability.

We use 2% or more silver brazing for strong, leak-proof joints.

Our manufacturing techniques and products conform to ROHS, CE, and ISO standards.

Proven expertise in Copper Y-Joints, VRF Branch Piping Kits, Copper Assemblies & Components.

Over 15+ years of hands-on experience as a leading VRF Y Branch Manufacturer and supplier.

Tailor-made components with customised insulation and packaging options.

FAq's

What makes your VRF copper joints "premium" compared to standard fittings?

Our joints are premium due to precision manufacturing and brazing with 2% or more silver alloy. This combination ensures superior corrosion resistance, optimal refrigerant flow, & leak-proof integrity under high-pressure cycling, directly contributing to system efficiency and longevity.

Can you manufacture custom VRF Y joints for specific project designs?

Absolutely. Customization is our specialty. We can manufacture Customised Premium VRF Y Joints to unique angles, branch configurations, and size combinations (from 1/4" to 2-1/8"). Send us your drawings or specifications, and our engineering team will provide a solution tailored to your exact piping layout requirements.

What is your standard lead time for orders, and do you offer expedited services?

Lead times depend on order specifications, customization level, and delivery location. We confirm accurate timelines after reviewing your requirements and always aim to support your project schedule.

Are your products suitable for use with both R410A and R32 refrigerants?

Yes. All our VRF Copper Y Joints and Copper pipe Connectors are manufactured and cleaned to be fully compatible with modern refrigerants like R410A and R32. Our brazing materials and processes prevent any contamination that could compromise system performance or safety.

What quality certifications do you hold, and how is quality controlled?

We are committed to certified quality. Our facilities and processes adhere to ISO 9001:2015. Every production batch undergoes stringent checks, including dimensional verification, visual inspection, and the critical 5.2 MPa pressure test. Certificates of Compliance and test reports are available with shipments.

Do you supply complete VRF branch piping kits, and what do they include?

Yes, as a leading Copper Branch Piping Kit manufacturer & supply complete, ready-to-install kits. These typically include pre-configured copper Y joints, and proper copper connectors, significantly reducing on-site labor and installation errors, along with insulation for both suction side & liquid side lines.

What are the advantages of using 2% silver brazing for your joints?

Using 2% or Higher Silver Brazing creates a stronger, more flexible seam than standard low-silver or phosphorous-copper alloys. This results in a joint better able to withstand vibration, thermal expansion/contraction, and physical stress, drastically reducing the risk of fatigue cracks and leaks over the system's lifetime.

Do you offer products with pre-installed insulation?

Yes, we provide VRF Y joints with insulation as a value-added service. The insulation is precisely cut & fitted to ensure complete coverage without gaps, improving thermal efficiency & preventing sweating, while delivering a neat & professional factory-finished appearance.

What industries and applications are your copper fittings designed for?

Our Copper Fittings and Components are primarily designed for precision HVAC&R applications, including VRF/VRV systems, chiller plants, and refrigeration. They are also suitable for other high-purity fluid and gas conveyance systems where leak-proof integrity and material purity are critical.

How do you ensure consistency and traceability in your manufacturing?

We ensure consistency through automated processes and meticulous record-keeping. Each product batch is traceable from raw material lot numbers through every manufacturing step. This full traceability allows for precise quality control and provides our clients with complete confidence in the reliability of every component we supply.