Headers

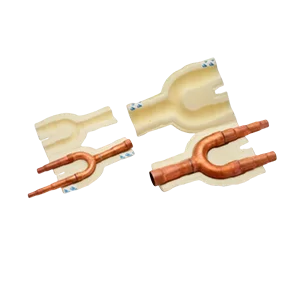

Customized insulation

At 227 Enterprise Pvt Ltd, customization defines our approach. We offer XLPE, EPP, EPS, and NBR insulation, each chosen for dependable thermal performance, durability, and easy installation. This range allows better matching with varied system designs, site conditions, and long term operating needs.

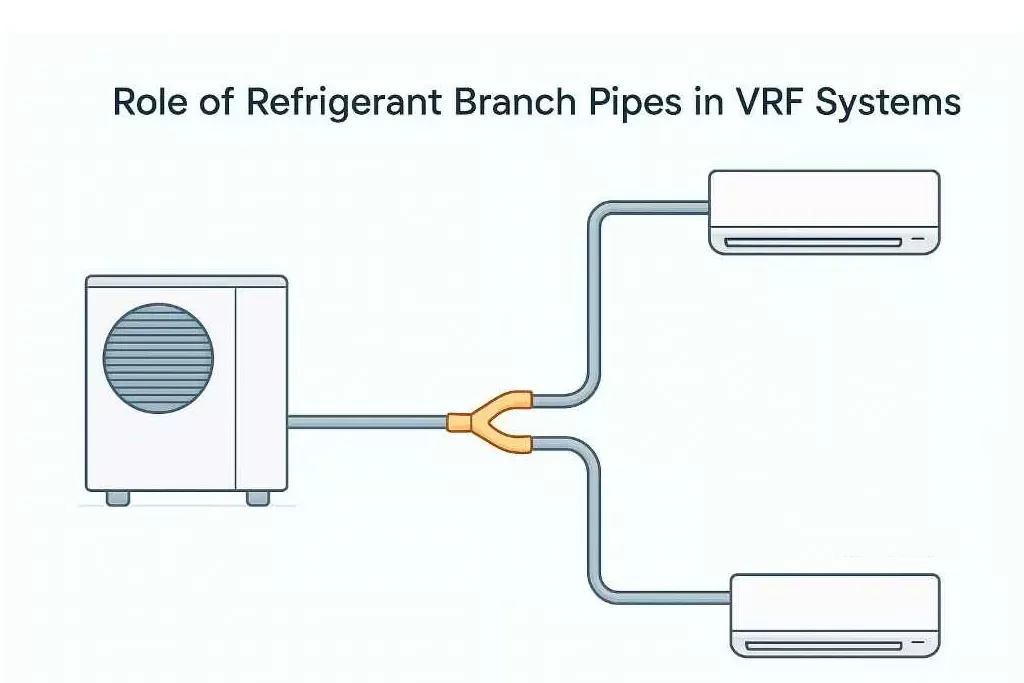

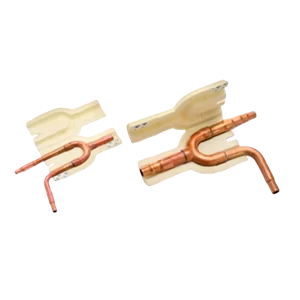

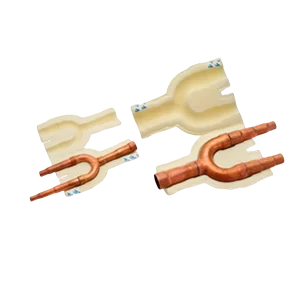

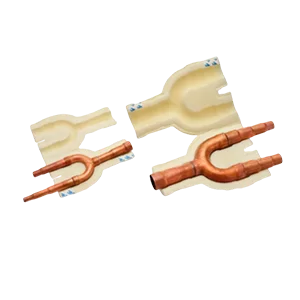

From complex VRF Y branches to multiport headers and detailed copper assemblies, our insulation is shaped for an accurate fit, neat finish, and lasting thermal performance. We don’t just make insulation, we create solutions that reflect genuine workmanship and help maintain consistent efficiency across long service life.

Customised

Insulation

FEATURES OF Customised Insulation

RoHS Compliant

CE Marked

FR Grade

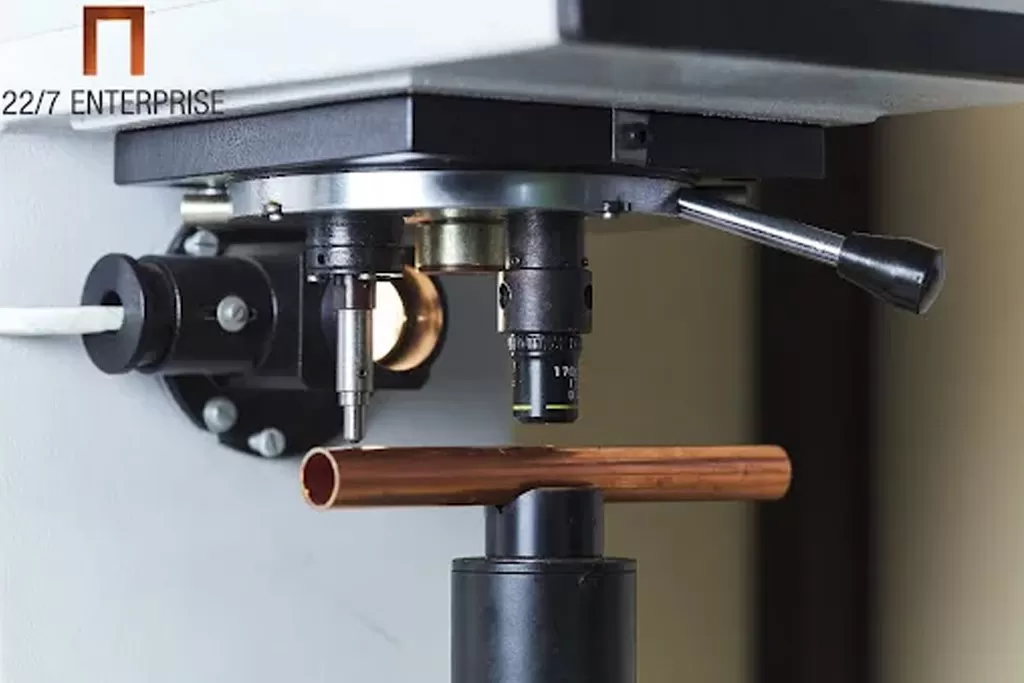

Laser CNC precision cutting

Thickness and material flexibility

OUR Products

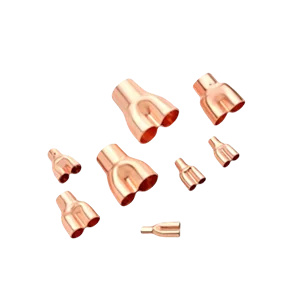

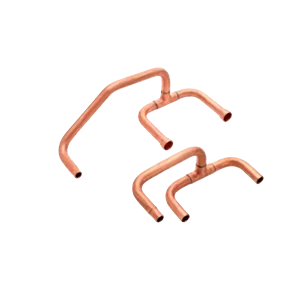

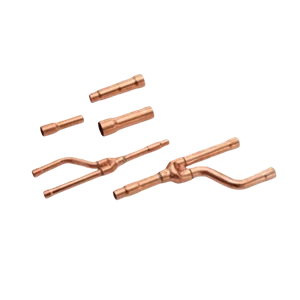

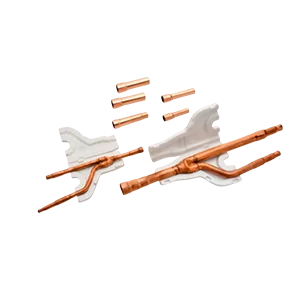

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

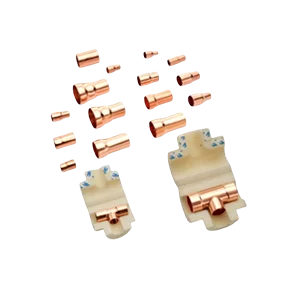

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

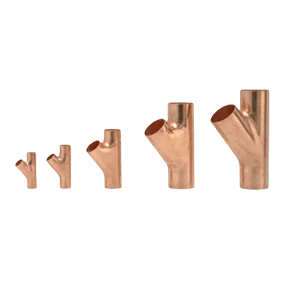

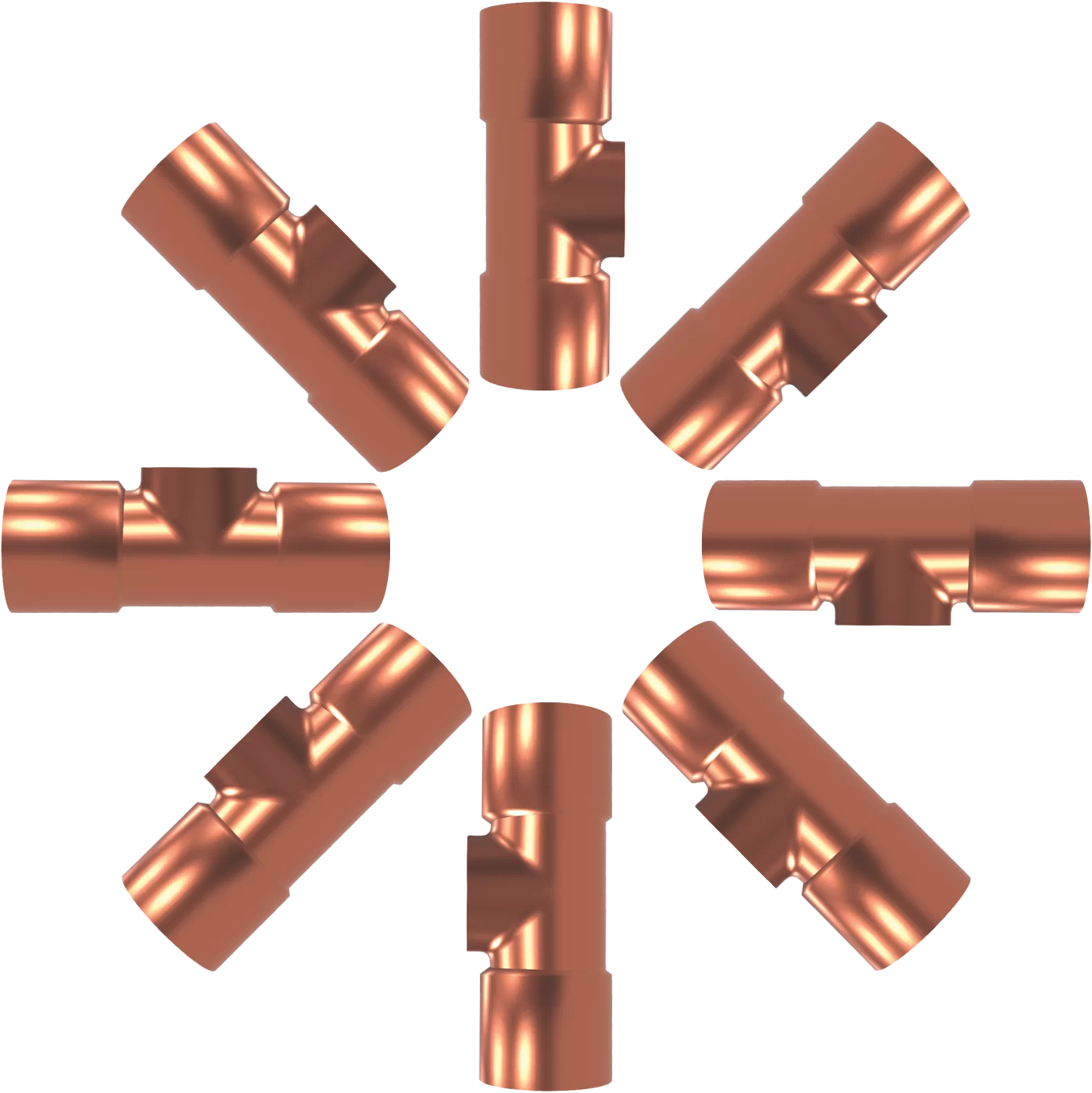

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

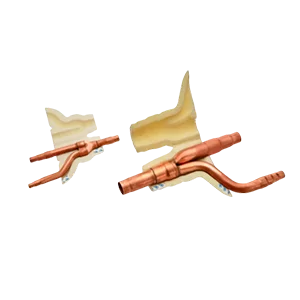

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

AX

Series

Engineered for high-performance R410a and next-generation-ready VRFXR ecosystems

View Details

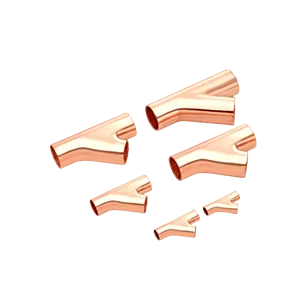

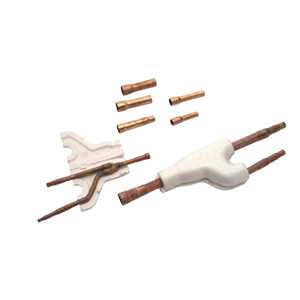

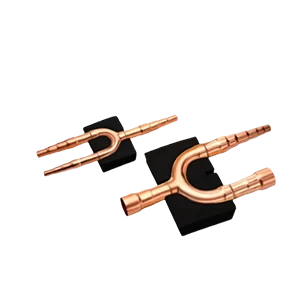

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

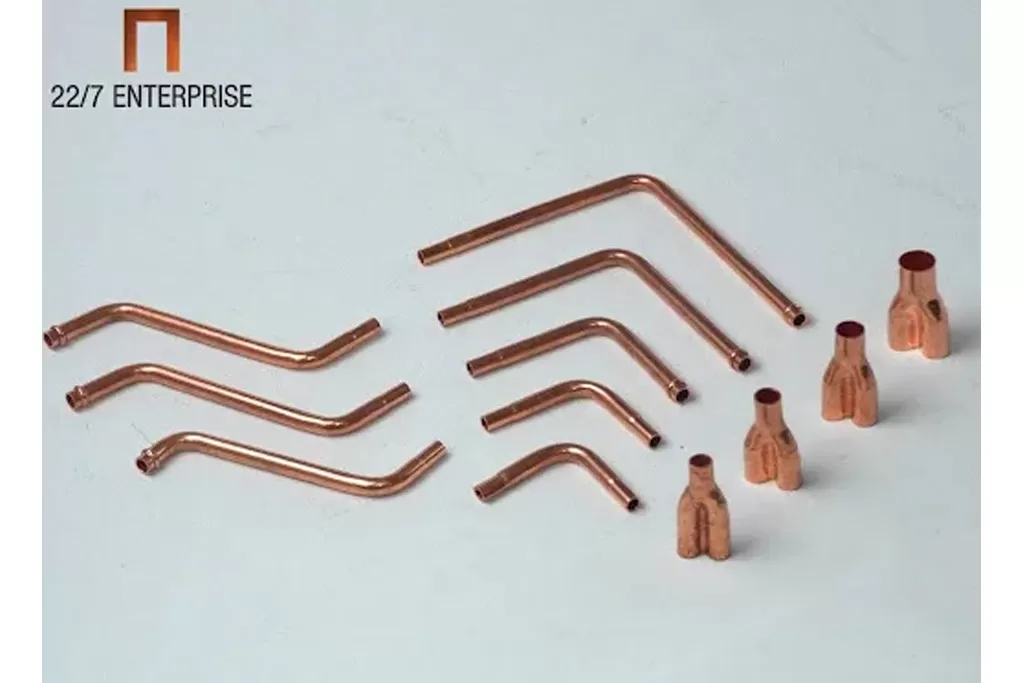

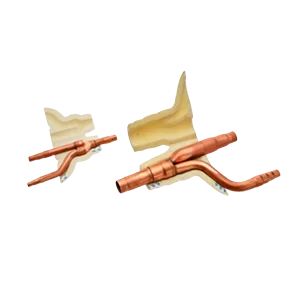

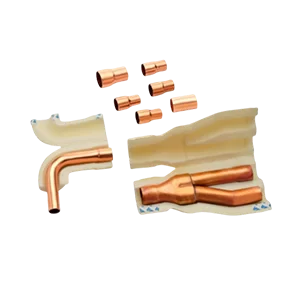

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

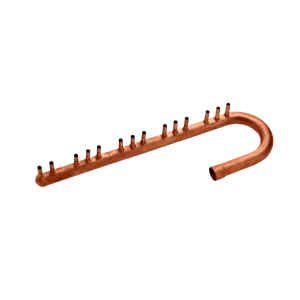

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

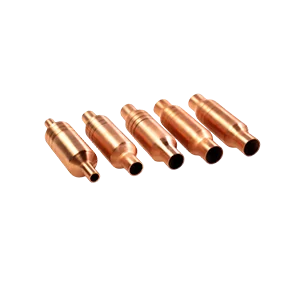

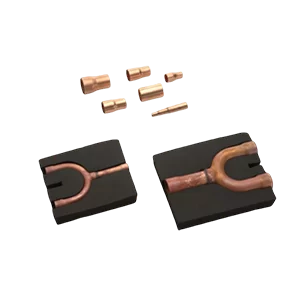

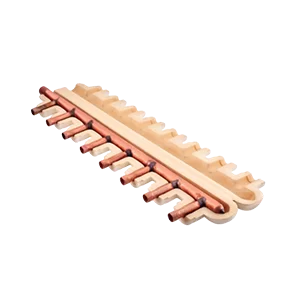

SAM

Headers

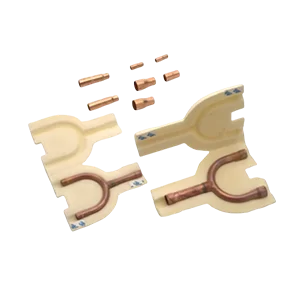

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

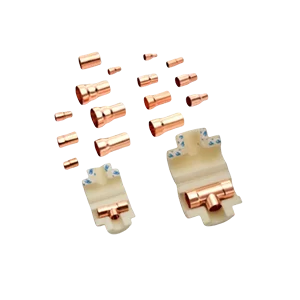

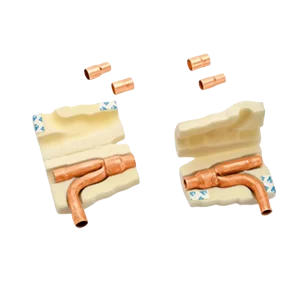

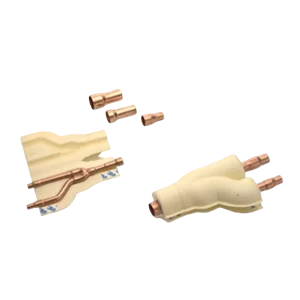

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

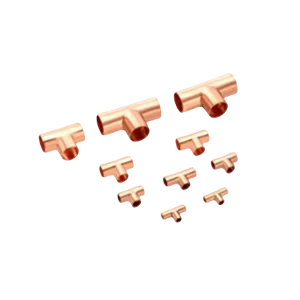

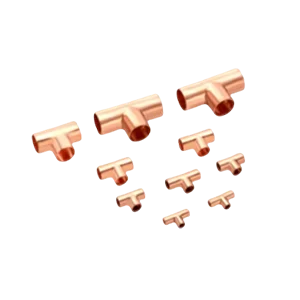

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

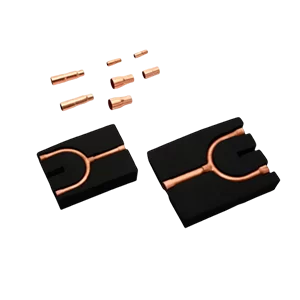

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The precision‑cut insulation for our VRF/VRV project eliminated on‑site trimming and ensured a perfect seal every time.

Project Manager, MEP Contractor,

UAEAs a consultant, I specify 227 Enterprise for customized insulation because their material certifications and OEM compatibility remove guesswork.

Senior HVAC Consultant, Engineering Firm,

IndiaTheir ability to deliver custom‑thickness NBR insulation for complex copper assemblies solved a persistent condensation issue on our site.

Site Engineer, Construction Company,

Saudi ArabiaThe FR‑grade XLPE insulation supplied for our high‑rise project met all fire‑safety standards without compromising thermal performance.

Procurement Head, MEP Consultancy,

Saudi ArabiaFast turnaround and exact fit for Mitsubishi Heavy Industries Y‑joints kept our installation schedule on track.

VRF Installation Specialist, HVAC Service Provider,

QatarOur Blogs

FAq's

What do you mean by Customized Insulation Solutions?

Special heat insulation Solutions resemble customized heat wrapping blankets that are cut and shaped to the precision of VRF/VRV copper parts, including Y joints and headers, and VRF/VRV assemblies. There are not any generic tubes but rather each is designed to fit the individual pipe sizes, joint shapes, and thicknesses that provide total coverage, high heat efficiency, and a professional finish to any HVAC&R work.

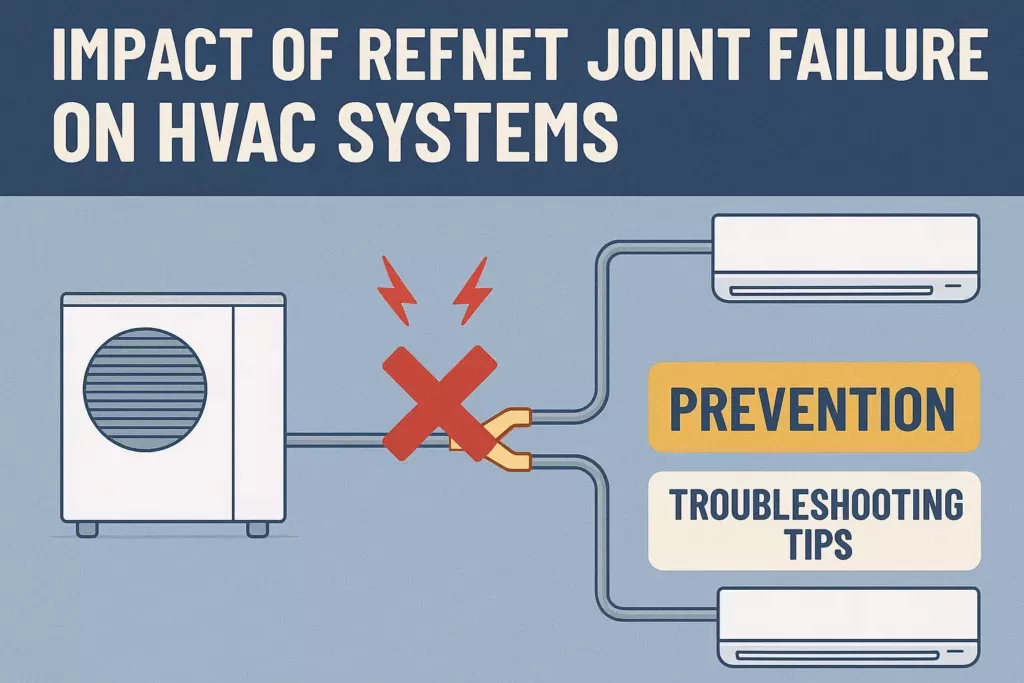

What is the significance of customized insulation on the VRF/VRV systems?

Such systems are based on the accuracy of the refrigerant flow and temperature difference. When the insulation is not fitted properly, it will leave holes that allow heat to escape and condensation to accumulate, thus depleting energy, rusting, and even shattering the system. Specially designed insulation edges around the sharp edges, maintain the temperature constant, prevent condensation and guard the efficiency and life of the system.

What are some of your insulation materials?

The available options include Cross-Linked Polyethylene (XLPE), which is fire resistant; Expanded Polystyrene (EPS), a cost-effective choice with good thermal performance; Nitrile Butadiene Rubber (NBR), known for its flexibility and strong resistance to condensation; and Expanded Polypropylene (EPP), which is lightweight, durable, and offers reliable insulation. You can choose the material that best matches your project in terms of thermal efficiency, safety needs, and ease of installation.

What is the best way to have a fine fit to intricate copper components?

We take your own CAD drawings and subject them to state-of-the-art CNC laser-cutting technology, which transforms the drawings into the perfect shapes of insulation. It will ensure the accuracy of the millimetre cuts on even the most difficult Y -joints and headers, bridging gaps that are impossible to bridge by cutting by hand, and resulting in a tight, smooth fit.

What are the main advantages of your customized insulation?

You have the best heat efficiency (are used to pay less on an electric bill), no condensation (no rust, drips), clean and pro appearance, fire-retardant safety, and RoHS/CE compliance. Tailoring also reduces wastage and conserves the workforce, and this reduces the total cost of the project.

How long is the average lead time of a custom insulation order?

The lead time for a custom insulation order typically depends on the order's complexity and quantity. We are happy to accommodate urgent requests whenever possible. To ensure a precise timeline for your specific needs, we can provide a firm deadline once we receive your specifications or drawings. This way, you'll have a clear expectation for delivery. Please feel free to share your project details, and we'll work with you to meet your schedule.

What does customized insulation set cost?

It will be determined by the kind of material you select (XLPE, EPS, NBR, EPP), the thickness required, the complexity of the shape, the number of units you would be ordering, and any other special certifications (such as FR grade). When we have your specifications, we will provide you with a detailed quote that has no hidden charges.

Do you provide samples before a large order?

Yes, we do provide physical samples before you commit to a large order. We typically mail out samples of the material and thickness you select, laser-cut to your requested shape. This allows you to examine the fit, quality, and material characteristics first-hand, ensuring you are completely satisfied before proceeding with the full production run.

What quality are your products of?

We take quality seriously, so you don’t have to second-guess what you’re getting. Our products follow RoHS and CE requirements and are manufactured in line with major ASTM standards. They’re also supported by recognitions such as ZED Gold, compliance with AS 4041 for pressure piping, and the ISO systems practiced by 227 Enterprise.

Fire safety is built into the material itself—we use FR-grade inputs that meet strict regulations. Beyond certifications, every batch is physically checked for the things that really matter on site: accurate dimensions, proper density, and dependable thermal performance. It’s our way of making sure each piece that reaches you works exactly as it should, every time.

Where do I request to have custom-made insulation?

Simply email us your components (CAD, PDF) or component specifications, such as pipe sizes, types of joints, material, and thickness at sales227enterprise.com. We will review your requirements, provide you with tech advice and a written quote. After giving the nod we begin precision production and deliver the parts.