VRF

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

- AX Series

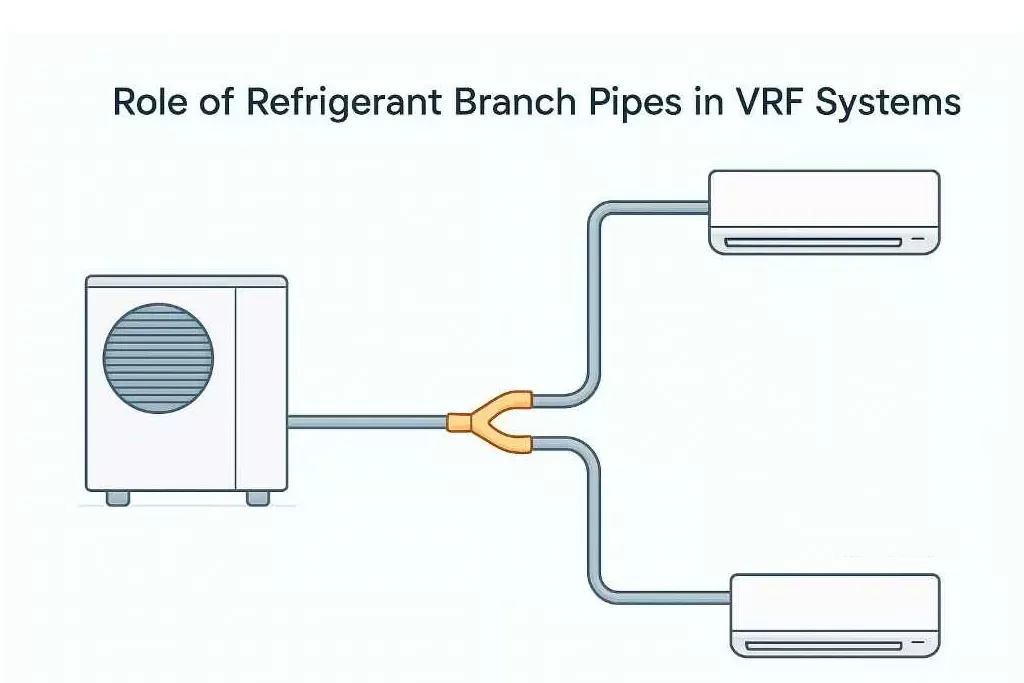

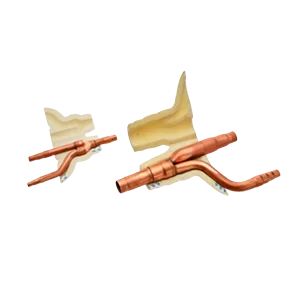

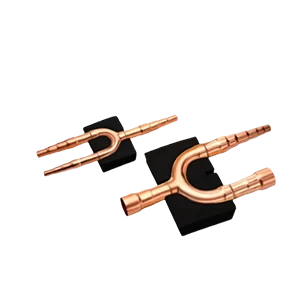

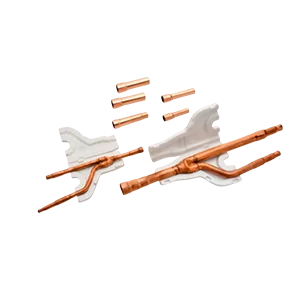

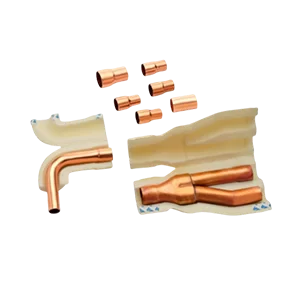

- VRF Y Joint

- VRF Branch Piping

- VRF Refrigerant Branch Piping

Headers

- SAM Headers

- TA Headers

- Customized Headers

Copper Components

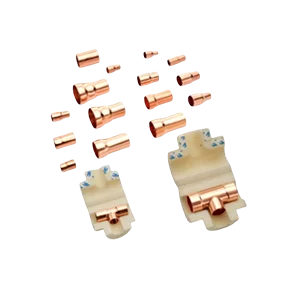

- Copper Compression T Fitting

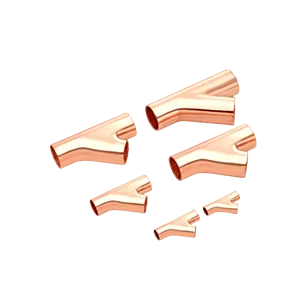

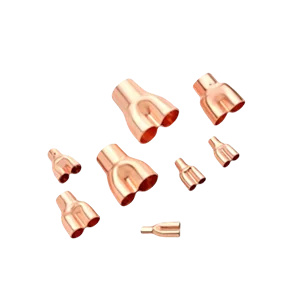

- Copper Y Fitting

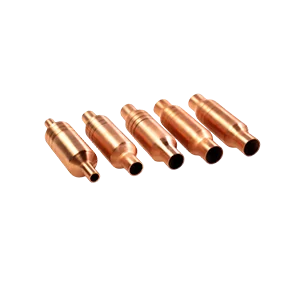

- Strainers

- Mufflers

- Stubs

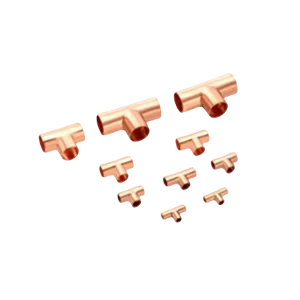

- Commercial Tee's

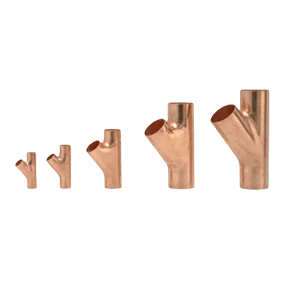

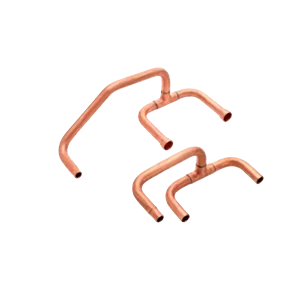

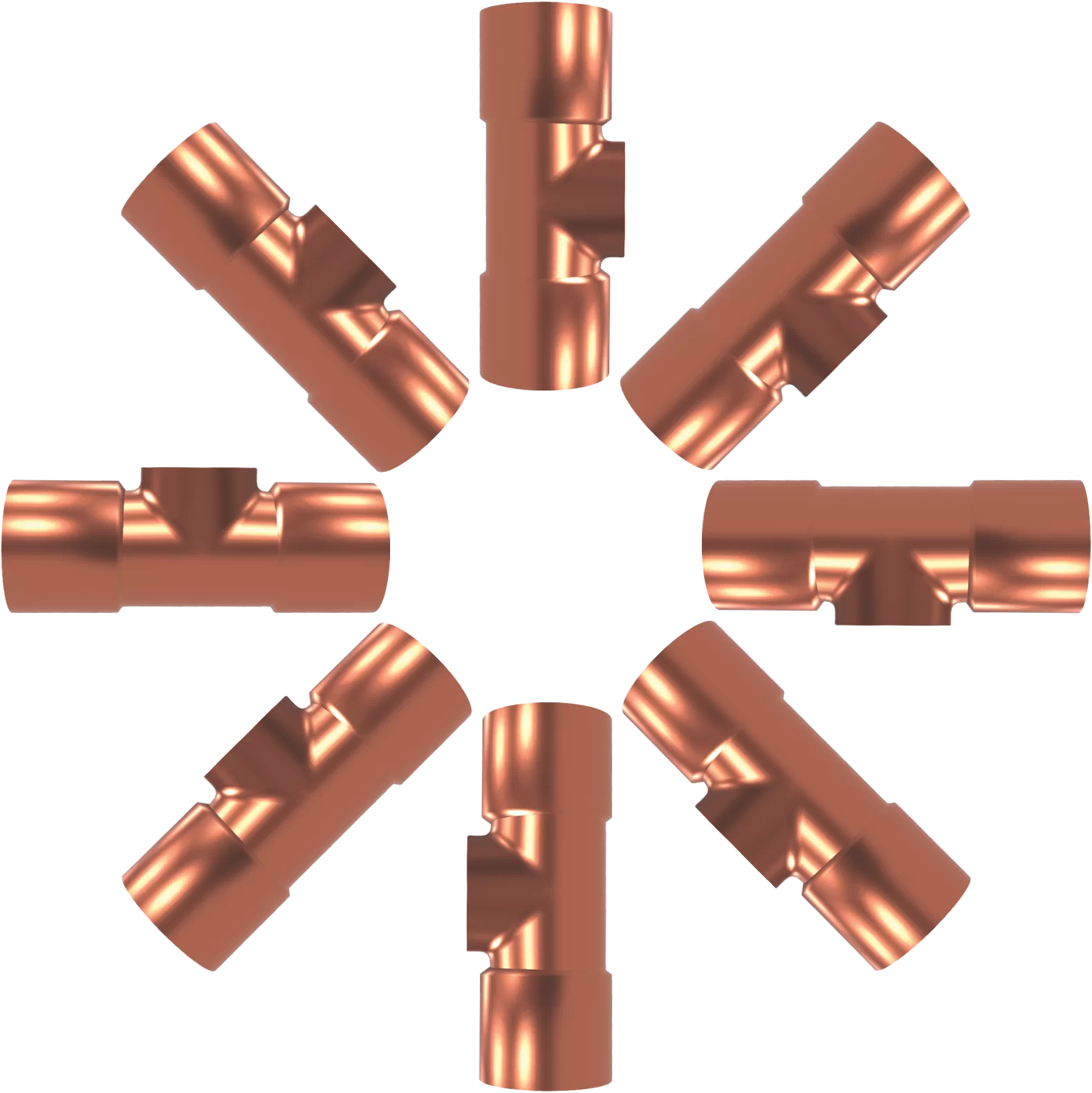

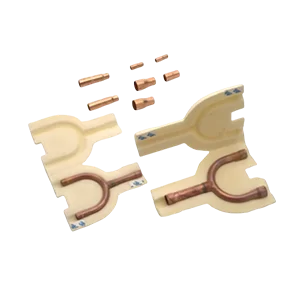

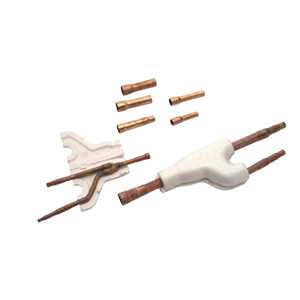

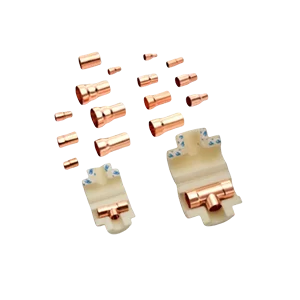

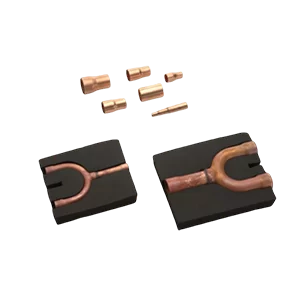

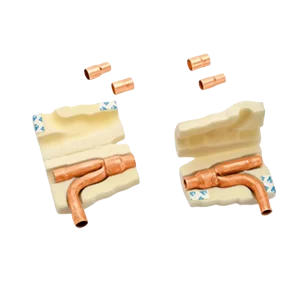

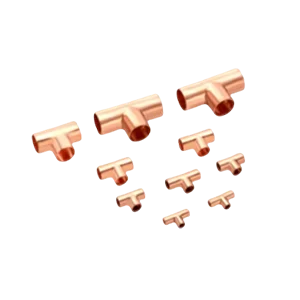

- Copper Tee Joint

- Y-Type Distributors

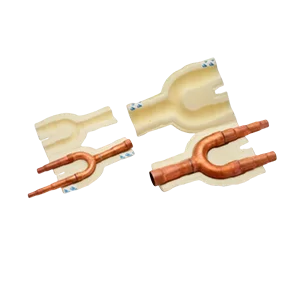

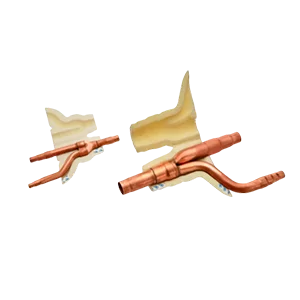

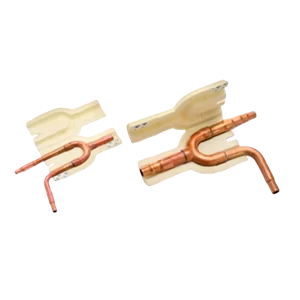

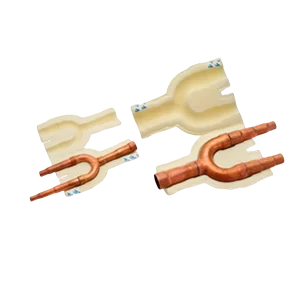

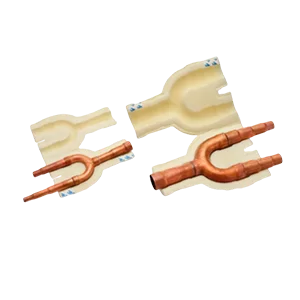

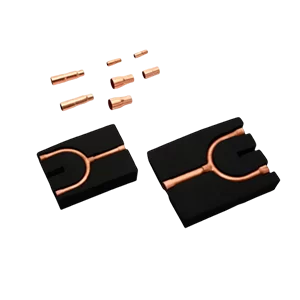

- Unbrazed U & Y Fittings

- Copper Y-Joint

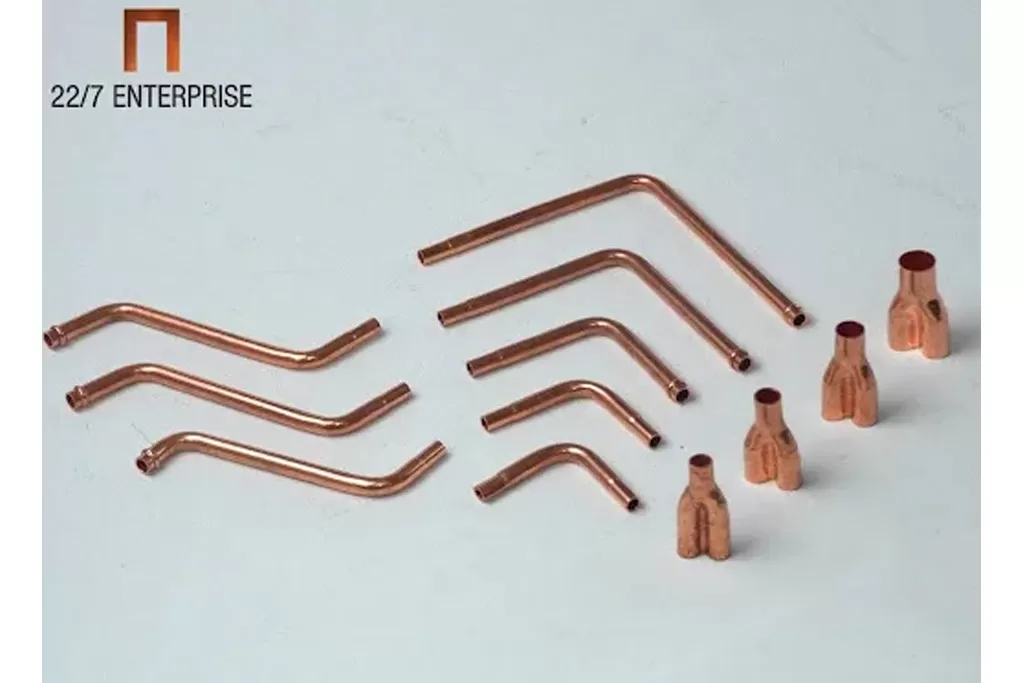

- Tubular Assemblies

Customized insulation

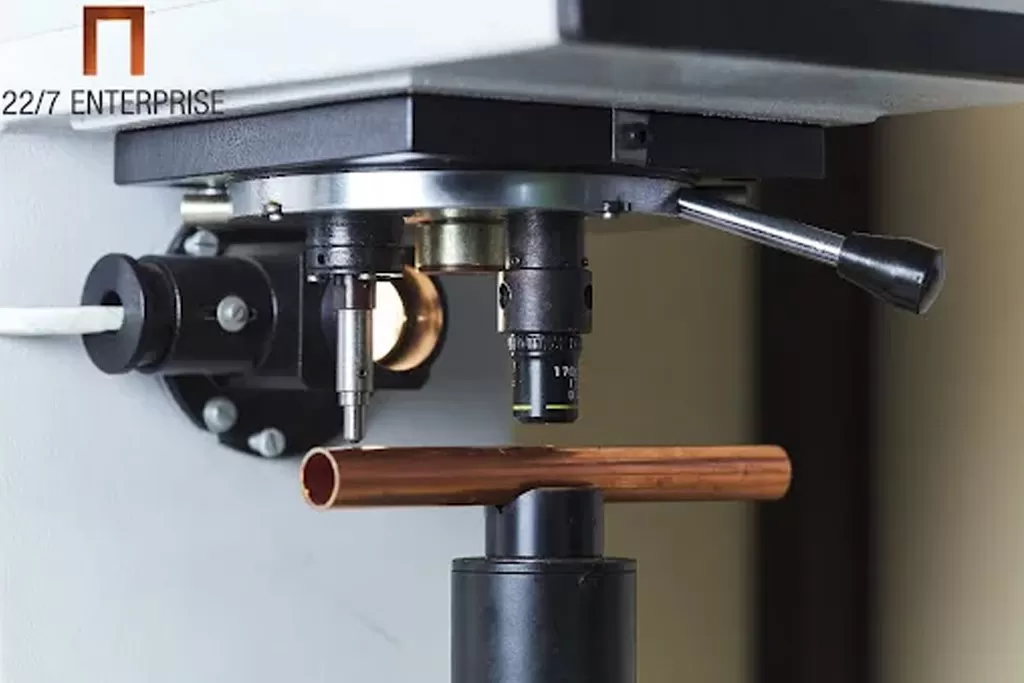

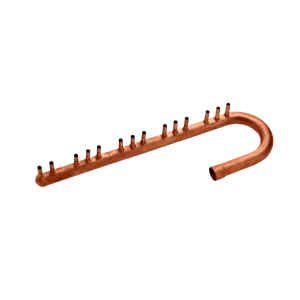

227 Enterprise produces copper tee joints for branch connections in HVAC&R and refrigeration lines. Made from refrigeration grade copper, they braze smoothly, keep refrigerant flow even, and remain dependable over time. Accurate sizing and close control help ensure proper fit and steady performance.

Our copper tee joints are offered in sizes from 1/4″ to 1 5/8″, so they fit easily into most copper piping layouts. They are made for straightforward installation and reliable day-to-day operation, matching well with standard pipes. When required, we also adapt the fittings to suit specific project needs and site conditions.

Copper Tee

Joint

FEATURES OF Copper Tee Joint

Leak‑Proof Seal

Pressure Tested 5.2 MPa

Multi‑Step Design

OEM Compatibility

Easy Installation

OUR Products

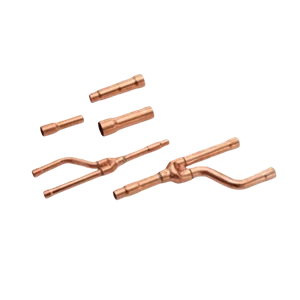

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

AX

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

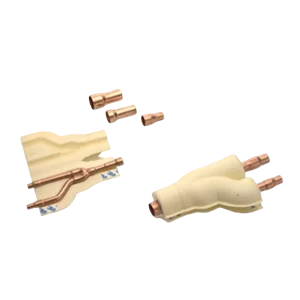

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

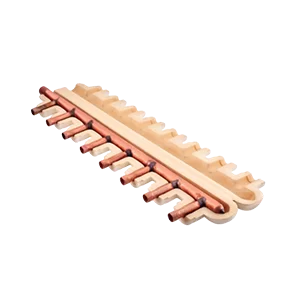

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The precision and leak‑proof performance of these tee joints have eliminated call‑backs on our high‑rise projects.

Procurement Head, MEP Consultancy,

Saudi Arabia227 Enterprise’s OEM‑compatible joints simplified our inventory and sped up installations significantly.

Project Manager, HVAC Contractor,

UAETheir pressure‑tested certification gave us the confidence to specify them for a critical hospital VRF system.

Design Engineer, Consulting Firm,

IndiaReliable delivery and technical support make 227 Enterprise our preferred supplier for custom VRF joints.

Purchase Director, System Integrator,

QatarThe multi‑step design allowed us to use the same joint across different pipe sizes, cutting project costs.

Site Supervisor, Mechanical Contractor,

OmanOur Blogs

FAq's