VRF

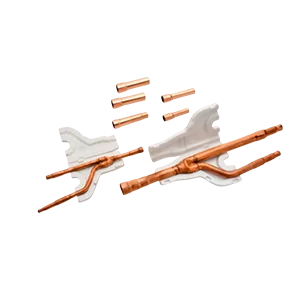

- Universal Branch Pipe

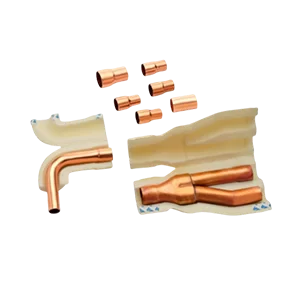

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

- AX Series

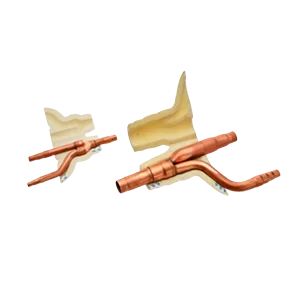

- VRF Y Joint

- VRF Branch Piping

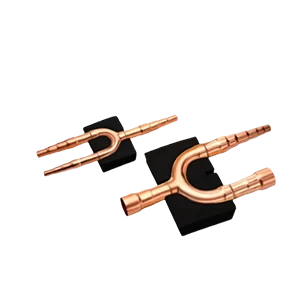

- VRF Refrigerant Branch Piping

Headers

- SAM Headers

- TA Headers

- Customized Headers

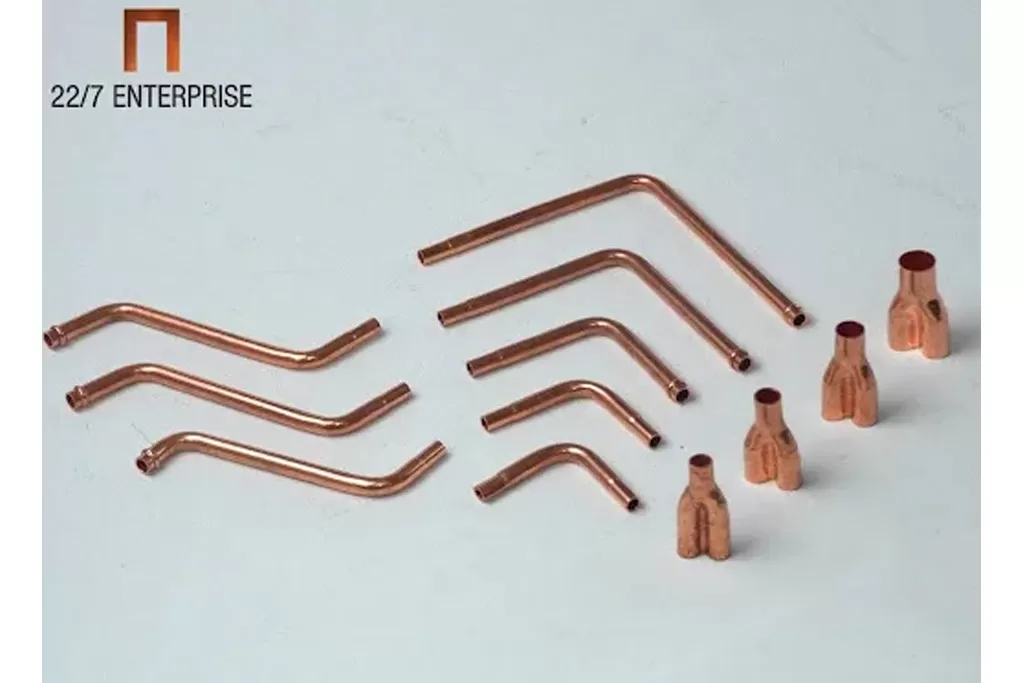

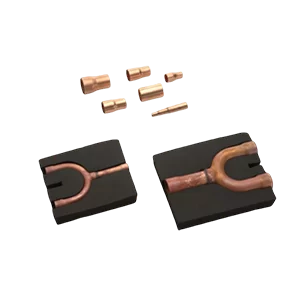

Copper Components

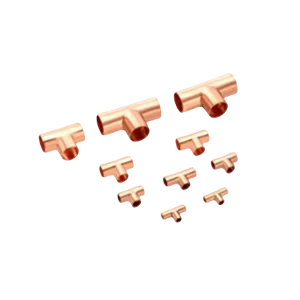

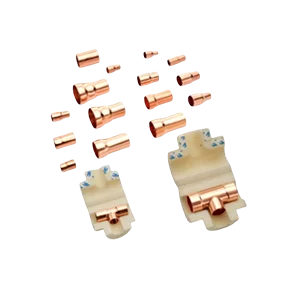

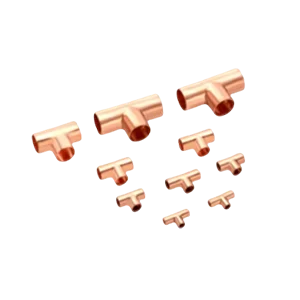

- Copper Compression T Fitting

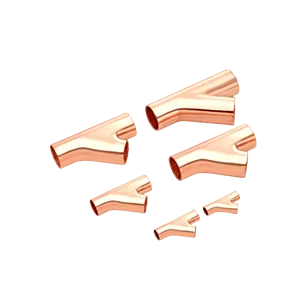

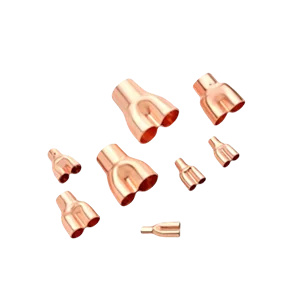

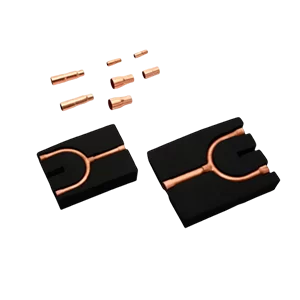

- Copper Y Fitting

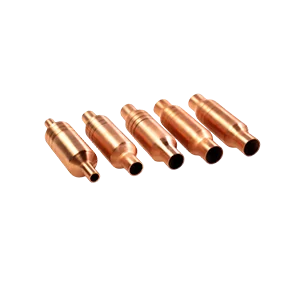

- Strainers

- Mufflers

- Stubs

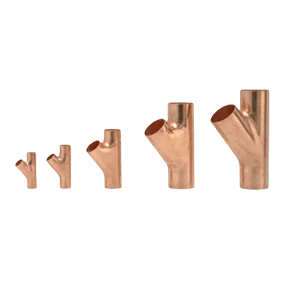

- Commercial Tee's

- Copper Tee Joint

- Y-Type Distributors

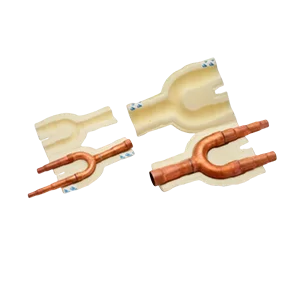

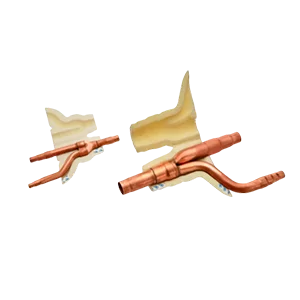

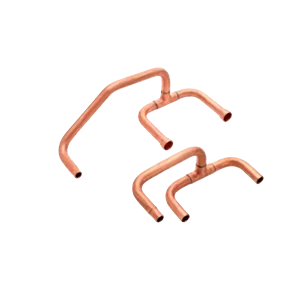

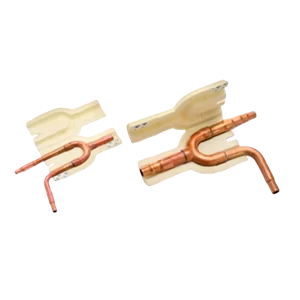

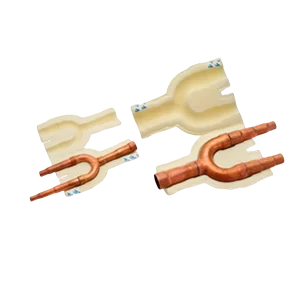

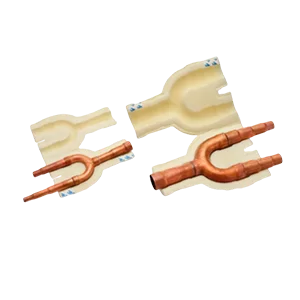

- Unbrazed U & Y Fittings

- Copper Y-Joint

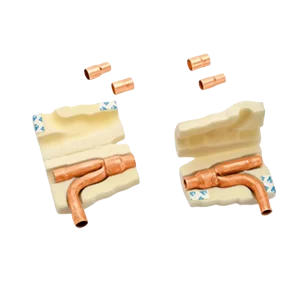

- Tubular Assemblies

Customized insulation

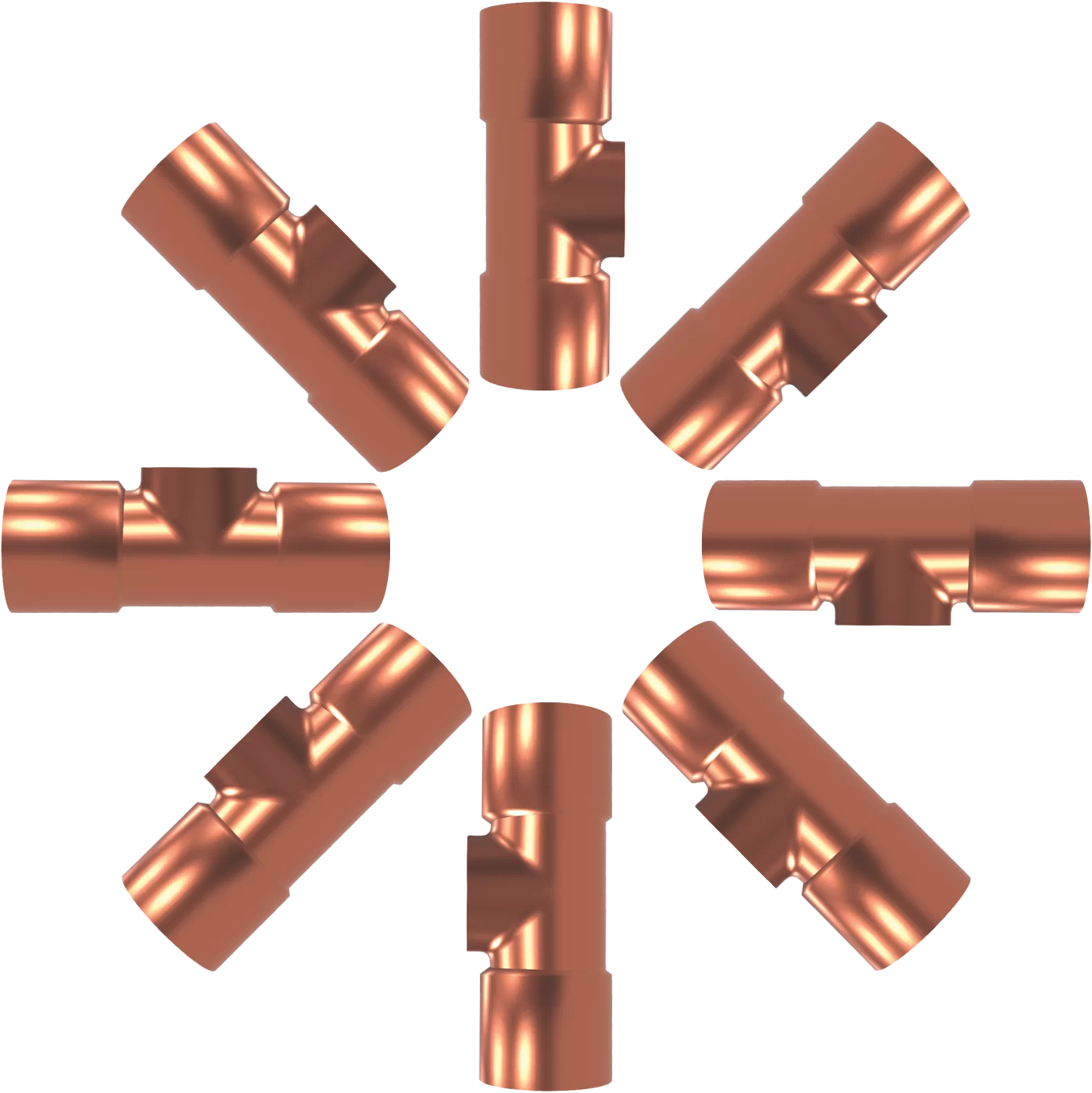

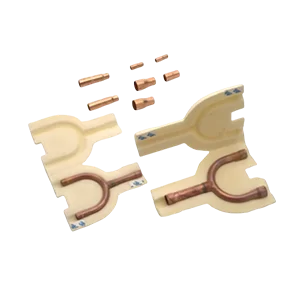

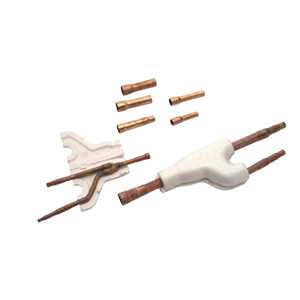

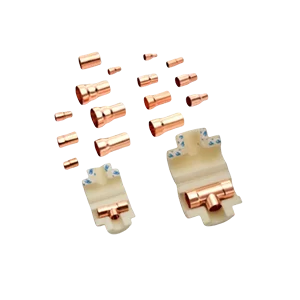

Copper Compression T Fittings

Premium Copper Compression T Fittings for VRF/VRV Systems

227 enterprise is one of the leading manufacturers and suppliers of custom copper Y fittings. We design them to be made precisely what is required by the HVAC&R systems. The fittings are allhihg quliayt copper and can be of all sizes big or small, hence are suitable for any layout of pipes

We assure you that the fittings are superior to the customary ones. They are washed and sterilized with nitrogen and to maintain the inside parts even cleaner and to remain environmentally friendly, we adhere to RoHS regulations which make the fittings not leak.

Copper Compression

T Fittings

FEATURES OF Copper Compression T Fittings

Copper Compression T Fittings

Engineered for VRF/VRV

Corrosion & Crack Resistant

OEM-Compatible & Customizable

Tested, Guaranteed Performance

OUR Products

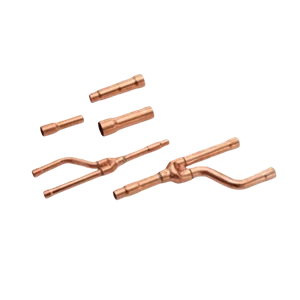

Universal

Branch Pipe

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

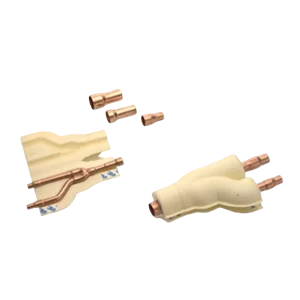

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

ME

Series

VRF Tee Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

AX

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

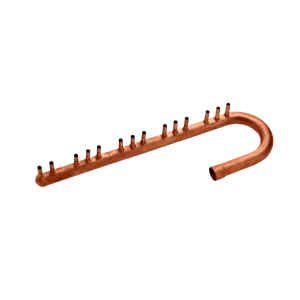

VRF Y

Joint

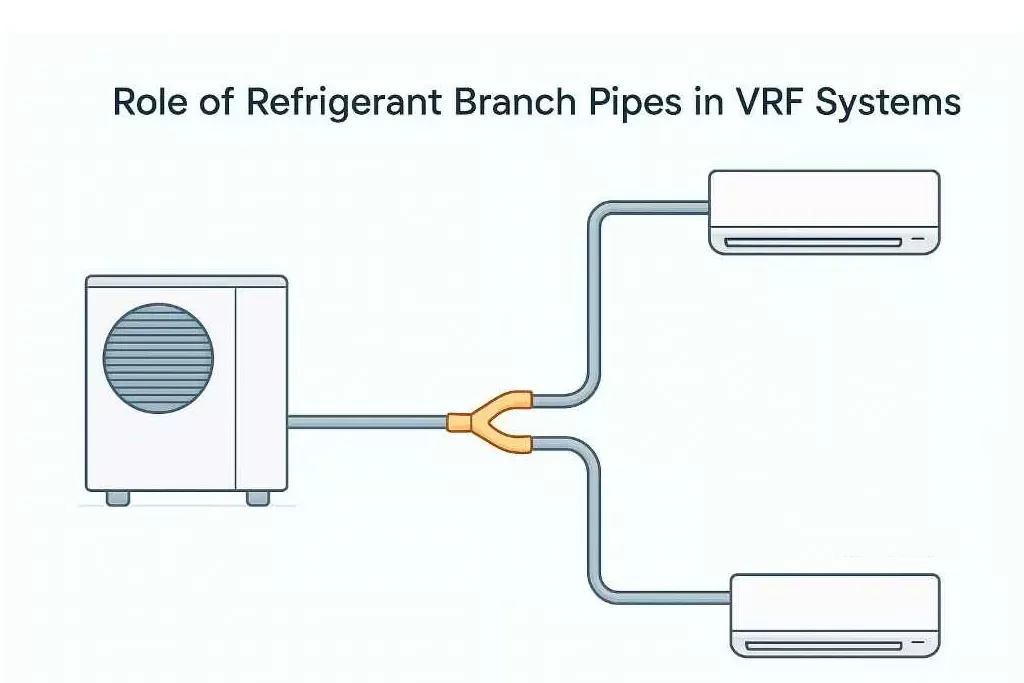

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

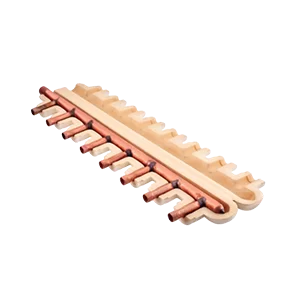

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The dimensional accuracy of 227's compression tees eliminated on-site rework and guaranteed a leak-free pressure test on the first try for our high-rise project.

Project Manager, Commercial HVAC Contractor,

UAEAs an OEM, we source Copper Tee Fittings for critical branch lines. 227 Enterprise's consistent quality and material traceability have made them a certified supplier for our assembly lines.

Procurement Head, MEP Consultancy,

Saudi ArabiaTheir technical team provided invaluable support in customizing tee angles for a retrofit, solving a major spatial constraint without compromising the system's flow dynamics.

HVAC Design Engineer, Consulting Firm,

IndiaWe standardized on 227 fittings across all our VRF installations. The reduction in callbacks for leak repairs has directly improved our profitability and client satisfaction.

Operations Director, Installation & Service Company,

QatarThe corrosion resistance in their fittings is noticeable. Even in coastal projects, we see no degradation, which protects our long-term maintenance contracts.

Service & Maintenance Head, Facility Management Company,

OmanOur Blogs

FAq's

Why do we have good fittings on R410A and R32 VRF systems?

We constructed them according to the high pressures and other refrigerant oils of those gases. We work with high-quality C12200 copper, which is strong and well-heated. It is an example that the fitting can accommodate any stress to the system and seal-tight using compression rings to prevent leakage and ensure the oil is solid throughout the entire life of the system.

Do you offer custom sizes or other sizes other than the six standard IDs?

Yeah, definitely. Custom building is a huge portion of our business, as a speciality maker. Copper Tee Fittings of non-standard branch-angles, larger or smaller ports, and other special sizes are often prepared by us to fit into narrow spaces or to be used in unusual system arrangements. Simply email us your drawings or specifications, and our engineering team will provide you with a speedy quote and investigate whether the project is feasible.

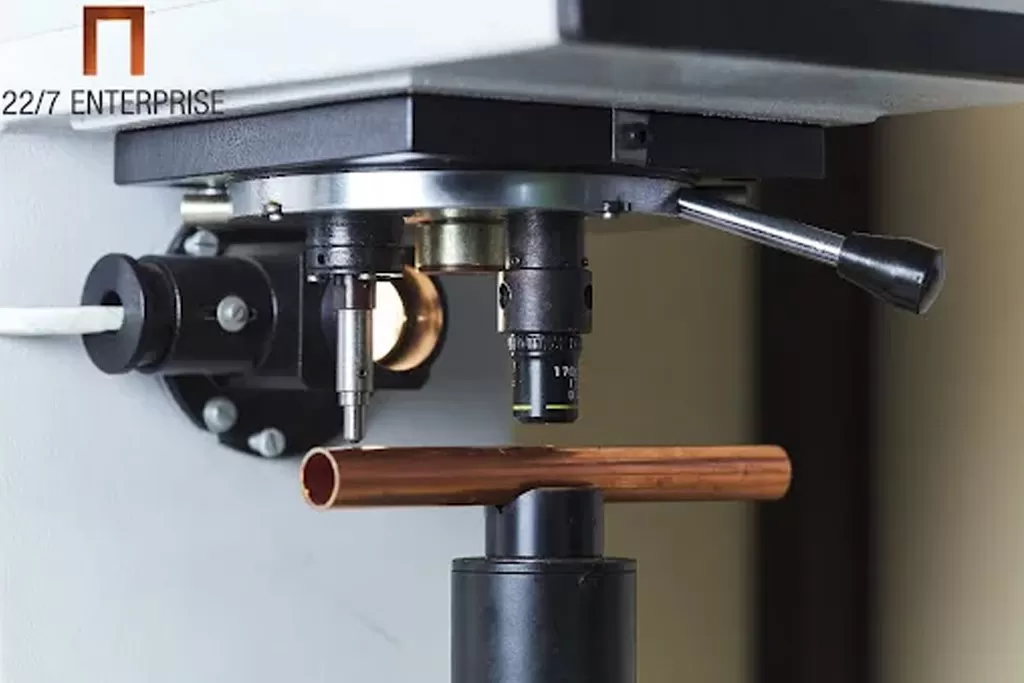

Which certifications and methods of testing do you implement?

All batches are subject to demanding in-house tests: size, material defect inspection through eddy-current, and hydrostatic pressure. We are guided by ISO standards, and we can provide material cert sheets on demand. We intend to maintain uniform, traceable quality, with a level of quality that matches or surpasses the levels required by big OEMs and big contractors.

Why does our fitting fit better than usual brazed ones?

The compression process provides a controlled mechanical seal, which is not as reliable as the welder. The sealing surfaces are smooth, with the tolerance being exact with our CNC machining. Combine it with a good-quality ferrule and the appropriate torque, and you have the effect of a uniform metal-to-metal seal, which withstands vibrations and temperature variations, which are frequent offenders that destroy brazed joints in the long term.

Do you support the major VRF/VRV OEM piping?

Regular sizes are kept in stock and can be shipped quickly. For tailor-made orders, lead times depend on the project requirements, order quantity, and delivery location. Once your order is confirmed, we provide a clear schedule and keep you updated throughout manufacturing and shipping.

What are the primary advantages of compression compared to brazed joints?

Its benefits are dependability, security and easy installations. Compression fittings remove fire danger, warmth, and fumes of brazing - needed when you need to be in congested or sensitive areas. They are quicker to install and are applicable in narrow spaces. Above all, they maintain a consistent seal that is not as likely to suffer the failures that manual brazing might experience.

What is the average turnaround time for standard and custom orders?

Regular sizes: stock in these sizes and can ship in 710 days. Tailor-made orders are based on the level of difficulty and quantity, although typically it needs 3-5 weeks. You place the order, and we provide you with solid schedules and update you during the process of manufacturing and shipping.

Is it possible to include the entire kit of ferrules and nuts?

Admittedly, we highly recommend and can supply a full matching set to some level, the highest sealing and system integrity - tee, nut, ferrule. Our kits are available in diverse materials to fit the diverse conditions, thus providing one trustworthy solution to the entire joint.

What is the benefit of the fittings in VRF energy?

A defective tee would result in turbulence or lost pressure or a blocked flow of oil, thus making the compressor work extra hard. Our accurate tees, through cutting flow resistance, ensure our system pressure is at the right place. That is to say, every indoor area receives the appropriate quantity of refrigerant charge, hence enabling variable-speed compressors to operate at the most efficient advantage, thus cutting power consumption directly.

What post-sales services and technical support do you provide?

We deliver more than delivery partners. We include detailed installation instructions, allowing you to tap into our engineers regarding on-site issues as well as system design. In case of any issue, it is sped up by our customer support and technical staff to ensure that your project is running on schedule and your HVAC is working.