VRF

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

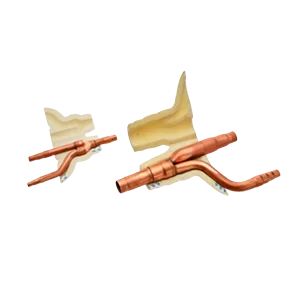

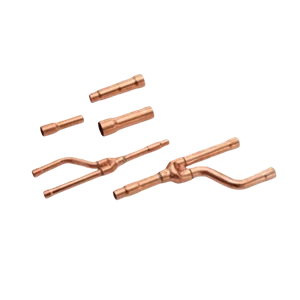

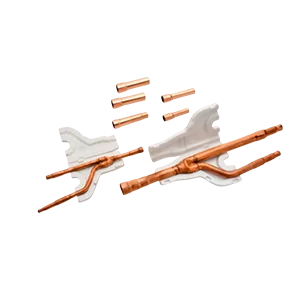

- VRF Y Joint

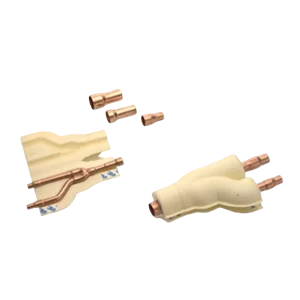

- VRF Branch Piping

- VRF Refrigerant Branch Piping

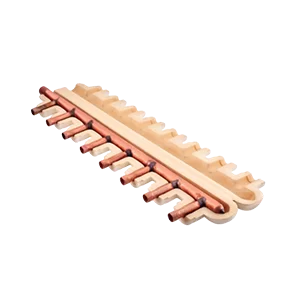

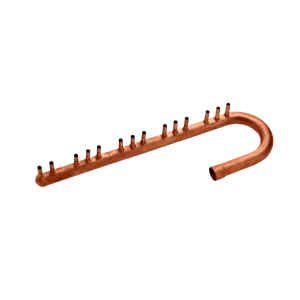

Headers

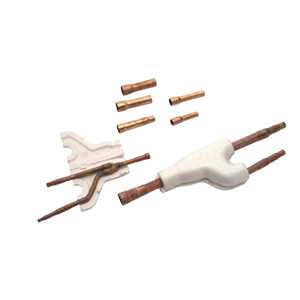

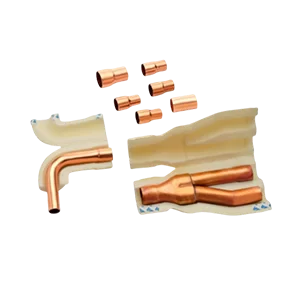

- SAM Headers

- TA Headers

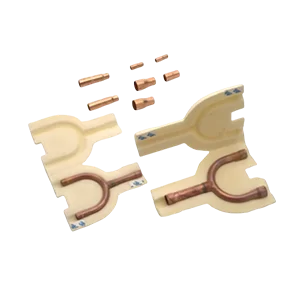

- Customized Headers

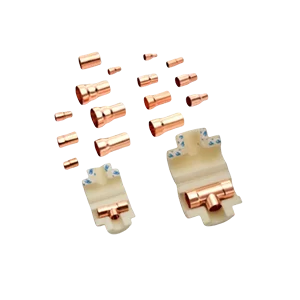

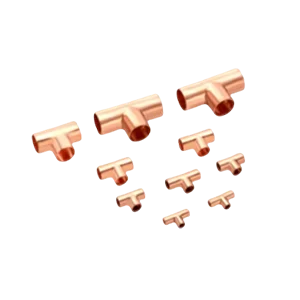

Copper Components

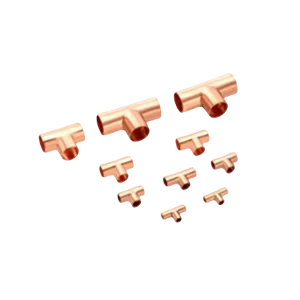

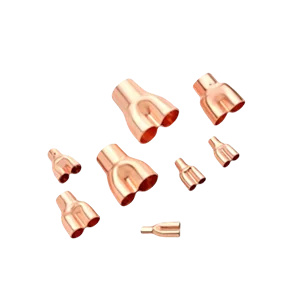

- Copper Compression T Fitting

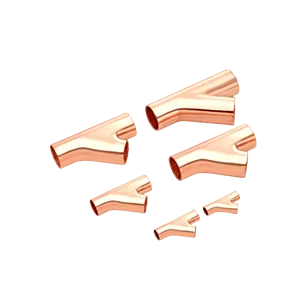

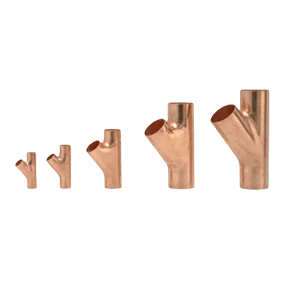

- Copper Y Fitting

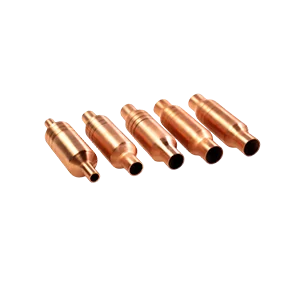

- Strainers

- Mufflers

- Stubs

- Commercial Tee's

- Copper Tee Joint

- Y-Type Distributors

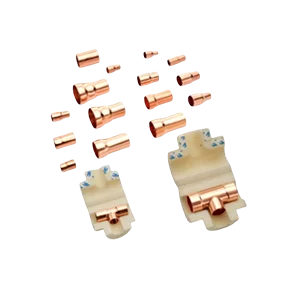

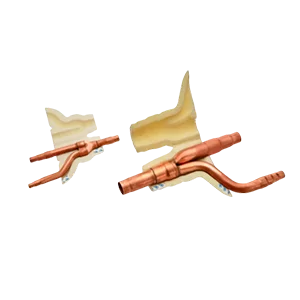

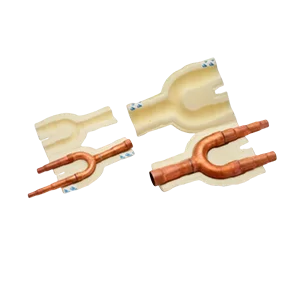

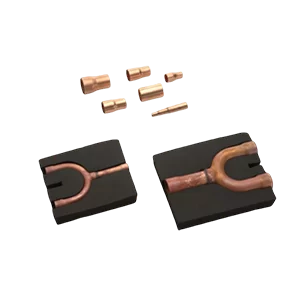

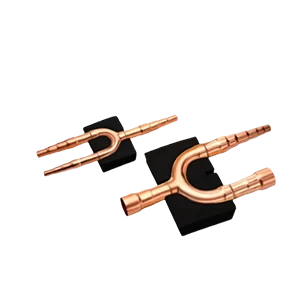

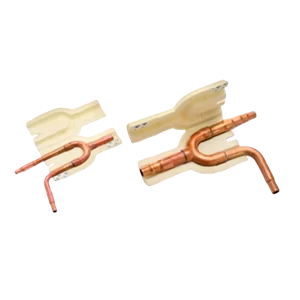

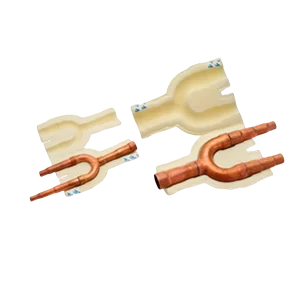

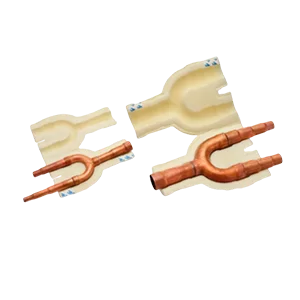

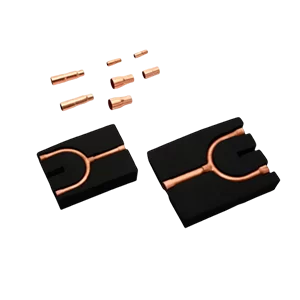

- Unbrazed U & Y Fittings

- Copper Y-Joint

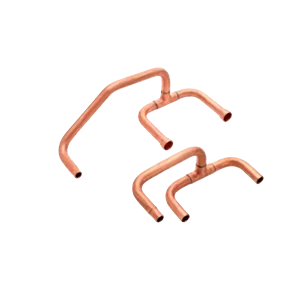

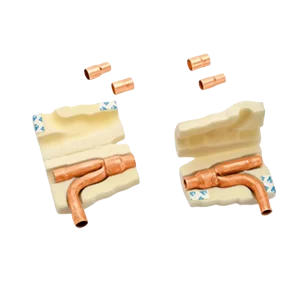

- Tubular Assemblies

Customized insulation

Customized

VRF/VRV Headers

Precision-Engineered Customized VRF Copper Headers for All Types of VRF Systems Working on R410A and Next-Generation Refrigerants

Customized

VRF/VRV Headers

FEATURES OF Customized VRF/VRV Headers

Multi-Port Configuration

5% Silver Brazing, Leak‑Proof

Robust Design

Easy to Install

Superior Thermal Insulation

Product specification (dummy)

| Pipe-A | Pipe-B | Pipe-C | |

|---|---|---|---|

| Pi-KHRP-22T (Gas Side) | 12.7 (1/2) – 15.88 (5/8) – 19.05 (3/4) | 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-22T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35(1/4) | 9.52 (3/8) – 6.35(1/4) |

| Pi-KHRP-33T (Gas Side) | 22.22 (7/8) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-33T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35 (1/4) | 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-72T (Gas Side) | 31.75 (11/4) -28,58 ( 11/8) – 25.4 (1) | 25.4 (1) – 19.05(3/4) – 15.88 (5/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-72T (Liquid Side) | 15.81 (5/8) – 12.7 (1/2) | 12.7 (1/2) – 9.52 (3/8) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-73T (Gas Side) | 38.10 (11/2) – 31.75 (11/4) | 31.75 (11/4) – 28.58 (11/8) – 25.4 (1) | 25.4 (1) – 19.05 (3/4) – 15.88 (5/8) |

| Pi-KHRP-73T (Liquid Side) | 15.88 (5/6) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) |

OUR Products

Universal

Branch Pipe

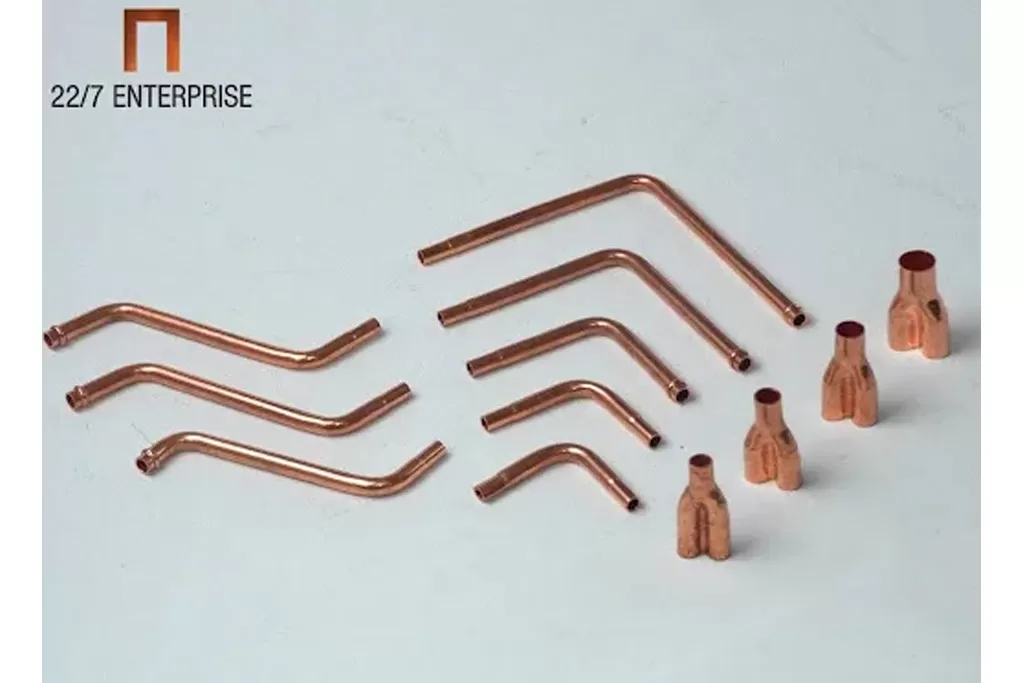

Precision-engineered universal branch pipe ensuring cross-OEM compatibility and leak-proof VRF connections.

View Details

DA

Series

Precision-engineered joints and fittings designed for performance in DA Series VRF/VRV applications.

View Details

ME

Series

Reliable copper fittings engineered to meet ME Series network specifications.

View Details

MI

Series

Durable refnet joints and branch pipes crafted for reliability in MI systems.

View Details

TA

Series

Precision TA Headers and refrigerant distributors for fit in SMMS & TA Header Series

View Details

GR

Series

Specialized fittings offering corrosion resistance and leak-proof integrity for GR heat recovery systems.

View Details

BSR

Series

Pre-insulated Branch Piping Kits for streamlined, error-free installation across OEM VRF platforms.

View Details

LG

Series

Compatible copper Y-joints and distributors meeting LG Multi V system standards.

View Details

HIT

Series

Custom-tooled fittings and joints ensuring optimal compatibility for HIT Series.

View Details

HAE

Series

Robust VRF Refrigerant Branch Piping to handle pressure and demands of HAE units.

View Details

CL

Series

Precision Copper REF Joints and assemblies engineered for operation in CL conditioning systems.

View Details

LNX

Series

Certified fittings and Copper Branch Pipe systems meeting specs for LNX VRF.

View Details

PNS

Series

Accurately machined joints and pipes deliver reliability for PNS ECOi and U-Series VRF.

View Details

TRN

Series

High-performance Copper Y Fittings and piping kits engineered with TRN Series VRF systems.

View Details

VRF Y

Joint

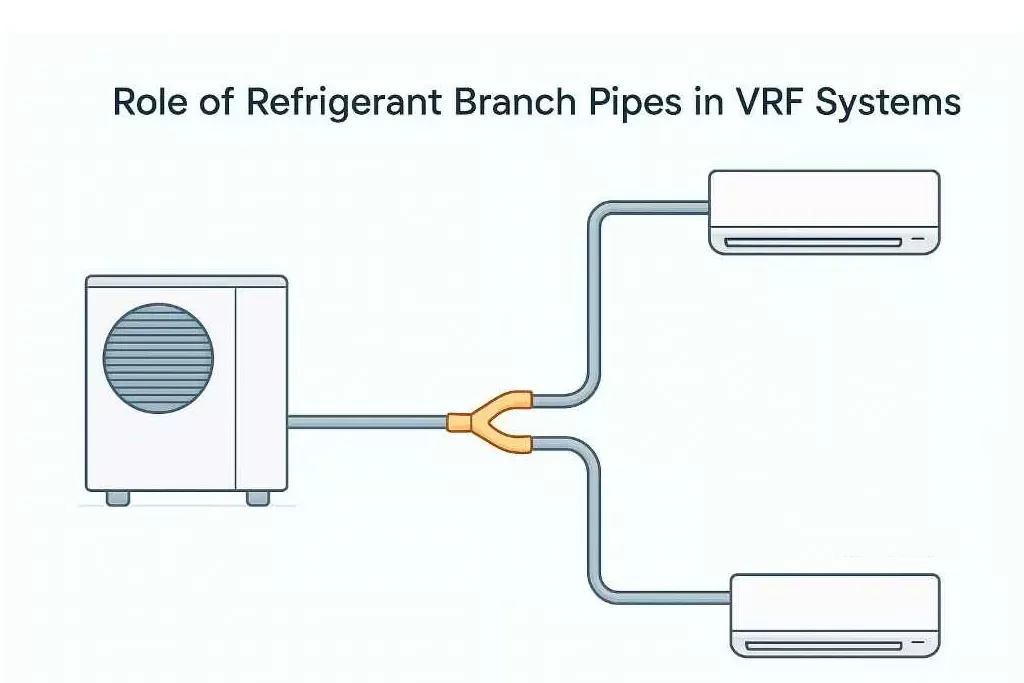

Core VRF Y joint ensuring balanced, turbulence-free refrigerant distribution for peak efficiency.

View Details

VRF Branch

Piping

All-in-one VRF refrigerant branch piping simplifying sourcing from one trusted supplier.

View Details

VRF Refrigerant

Branch Piping

Precision routing for multi-zone VRF system distribution.

View Details

SAM

Headers

OEM-specific SAM Headers and distribution joints ensure refrigerant management in DVM S systems.

View Details

TA

Headers

Precision TA Headers and refrigerant distributors for fit in SMMS and Daiseikai series.

View Details

Customized

Headers

Bespoke Customized Header assemblies designed to meet system layouts and multi-port requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The precise customization and flawless OEM fit of 227's headers eliminated compatibility issues on our large-scale commercial project, ensuring a smooth installation.

Procurement Head, MEP Consultancy,

Saudi ArabiaUnmatched reliability. Using these headers has virtually eliminated our leak issues, saving us thousands in refrigerant and wasted labor.

Service Director, HVAC Contracting Firm

UAETheir ability to deliver non-standard port configurations and lengths allowed us to meet unique architectural constraints without performance compromise.

Project Manager, Luxury Real Estate Developer,

IndiaThe quality is consistently exceptional, matching the demands of our premium VRF installations and giving us confidence in every system we commission.

Principal Engineer, Building Services Design Firm,

UKAs a supplier, 227 Enterprise's technical support and reliable lead times make them a foundational partner for our complex projects across Europe.

Supply Chain Manager, HVAC Equipment Distributor,

GermanyOur Blogs

FAq's

And why would a vendor of a Custom VRF Header make his product interoperable with other OEMs?

A real manufacturer of Custom VRF Headers can have true universal compatibility with a multi-step design that can support a wide range of pipe sizes with the same fitting. We go an extra mile by providing the full customization of port numbers (2-8) and the accuracy of internal diameters of 6.5mm to 38.3m at 227 Enterprise. This guarantees that our headers are compatible with the piping specifications of any major brand to choose, such that via only one inventory part we can fit into any other significant system.

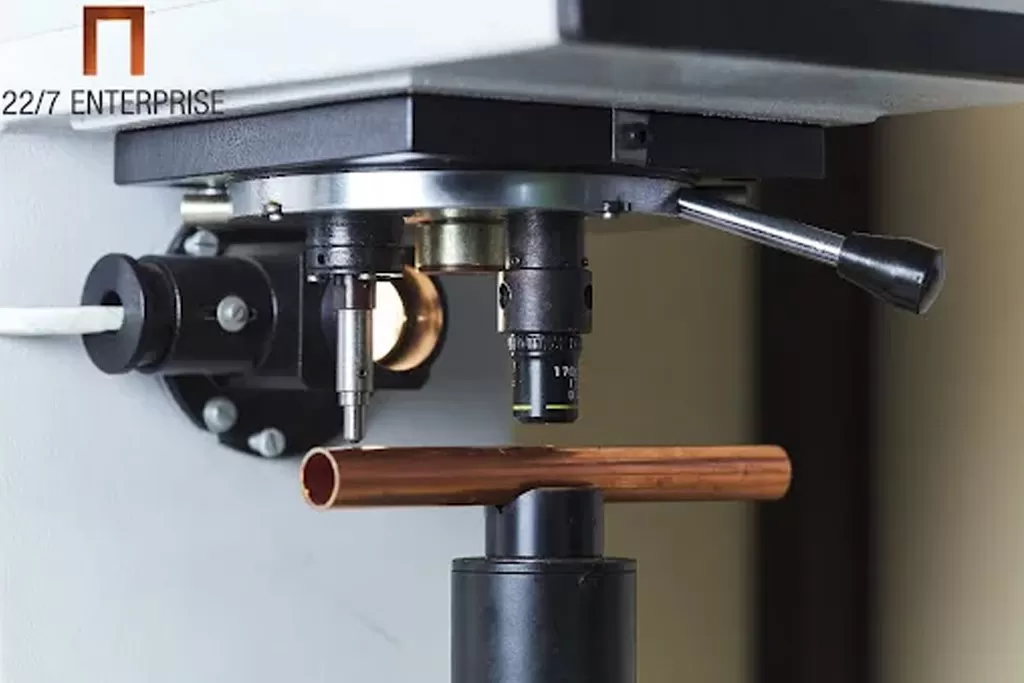

Why is 227 Enterprise brazed with 5% silver rods as opposed to lower or higher Silver content?

We have determined 5% silver-phosphorous-copper brazing alloys to be the best in terms of performance, reliability and value in VRF headers. This level of silver content gives much greater ductility and gap-filling properties over 0% rods to form Joints that resist crack propagation through vibration and thermal loads. Although 15 percent silver is easier to handle, the 5 percent alloy is adequate enough to create leak-proof integrity during copper-to-copper brazing with a high level of accuracy, which requires no extra cost to attain because the brazing process guarantees precision and factory-controlled uniformity, yet the cost is comparatively lower than we can dictate a superior, reliable product at a favorable price point.

How does your customised header's pressure rating and how do you verify it?

All of our customized headers undergo intensive pressure testing up to 5.2 Megapascals (MPa) of pressure before the departure of our plant. This test pressure is by far much higher than the actual operating pressure of both R410A and next-generation refrigerant systems, and thus the test pressure has a high safety margin. This 100 per cent testing procedure, along with our use of heavy-duty copper tube, with its solid, heavy walls, will ensure that every item shall run in an unblemished seal under actual installation conditions, which will guarantee safety, efficiency and durability of the system throughout the existence of the installation.

How customized will a VRF Customize Header Supplier be?

We pride ourselves on being a highly collaborative engineering partner rather than just a parts supplier. Our core service is built around adapting to your specific project requirements, whether for a complex retrofit, a space-constrained installation, or a prototype system. We work directly with you from concept to completion, offering genuine design flexibility to create the exact component your project demands.

What is the role of the insulation of customized headers in system efficiency in general?

Correct insulation is necessary to avoid the problem of condensing energy and ensure accurate refrigerant temperature. We offer these custom-fitted insulation jackets of such materials as fire-retardant XLPE or closed-cell NBR elastomeric foam that is carefully cut to conform to the unique shape of your header. This closes thermal insulation holes and provides the full thermal coverage, which has the direct ramifications of guaranteeing the rated SEER and COP efficiency of the system, through limiting thermal losses/gains at the points of distribution, thus safeguarding your investment in the high-efficiency VRF technology.

What are the lead-times of a custom-designed header and what are the inputs you require to begin with?

Customized header lead times depend on the complexity, although our specific manufacturing processes smooth lead times. To give a correct quote and start engineering, we need the information: the number of ports, inlet and outlet pipe IDs (in mm), desired wall thickness, length of the product, type of refrigerant and desired insulation material. A schematic or system diagram is provided to make the process faster. We value effective communication so that the finished product will be of exactly the specifications and project-time calculated.

Do you have international quality and safety products?

Yes. We have manufacturing processes and products of high international standards. All our copper components are produced out of certified C12200. Brazing and pressure testing (5.2 MPa) are carried out using our methods which give even higher integrity of the joints than industry requirements. Also, our insulation, including our FR-Grade XLPE and our ASTM E84-rated NBR, is of utmost fire safety and smoke development requirements to be installed in business and residential structures.

As the VRF market expands at a very high rate, how does 227 Enterprise keep its components up to date?

We plan the future of HVAC. Our headers are designed with the capability to be compatible with the existing R410A systems as well as successive generations of refrigerants with lower Global Warming Potential (GWP) such as R32. This is in the choice of the materials, excellent design due to potentially increasing operating pressures, and consideration of trends in the industry. Being your customize Header VRF Systems Manufacturer, you ensure a partner whose components provide us with potential interests on the long-term feasibility and functionality of your facilities.

What is your minimum order quantity (MOQ) of customized header?

We can learn that projects range from a one-unit retrofit to a large new building. Thus, we provide laxing MOQs to cater to the needs of all our clients. We will become a solutions partner, either a one-off design creation to solve a unique problem or a large volume production to create a large development. Get in touch with us directly so that we may listen to your scope and volume requirements in a particular project.

Are you capable of supplying complete refrigerant branch piping/kits, as well as individual headers?

Absolutely. We are a wholesome manufacturer and provide entire branch piping solutions for refrigerants. This may involve our tailor-made headers, copper Y-joints perfectly fitting, straight copper tubing of ACR, requisite reducers, and custom insulation of all items.