VRF

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

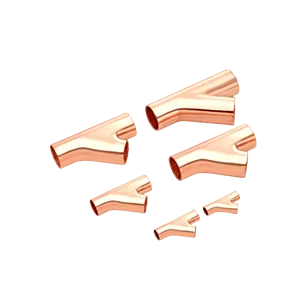

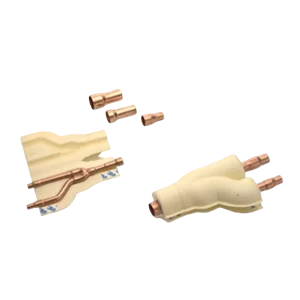

- VRF Y Joint

- VRF Branch Piping

- VRF Refrigerant Branch Piping

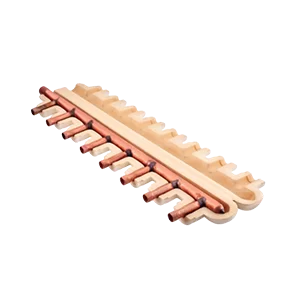

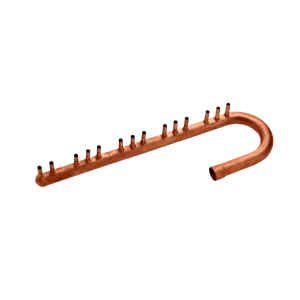

Headers

- SAM Headers

- TA Headers

- Customized Headers

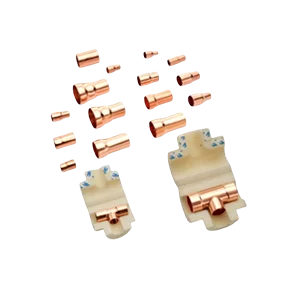

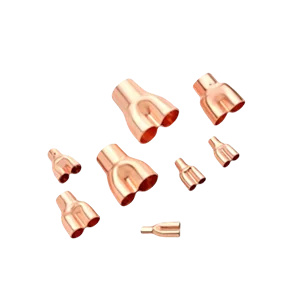

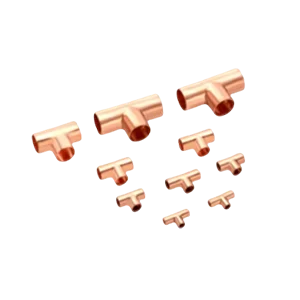

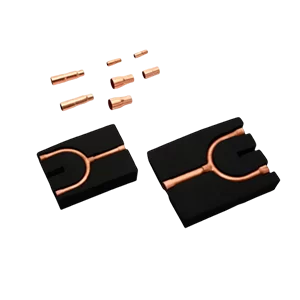

Copper Components

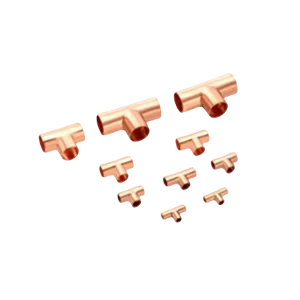

- Copper Compression T Fitting

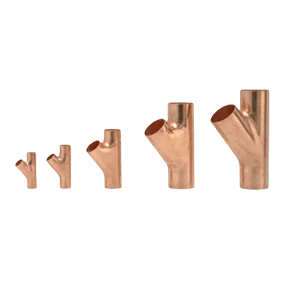

- Copper Y Fitting

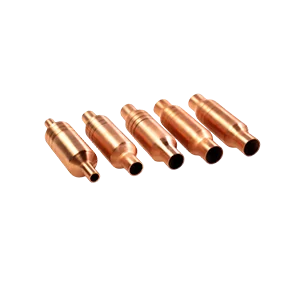

- Strainers

- Mufflers

- Stubs

- Commercial Tee's

- Copper Tee Joint

- Y-Type Distributors

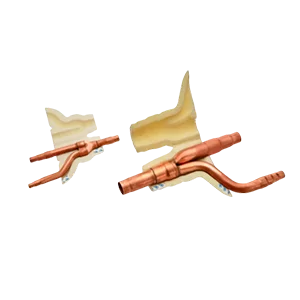

- Unbrazed U & Y Fittings

- Copper Y-Joint

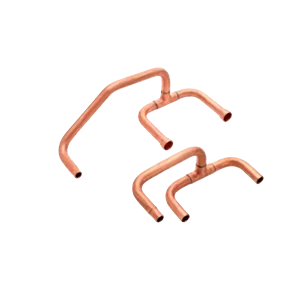

- Tubular Assemblies

Customized insulation

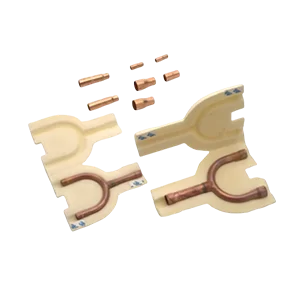

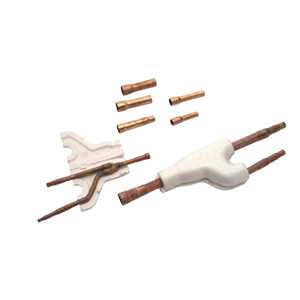

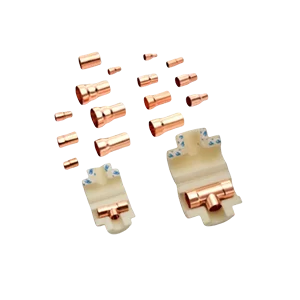

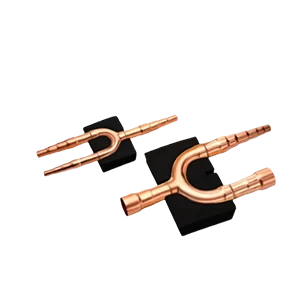

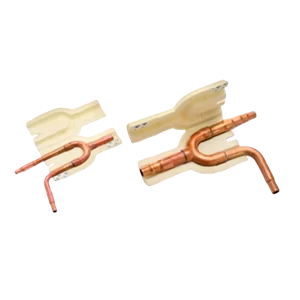

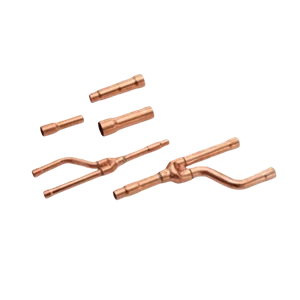

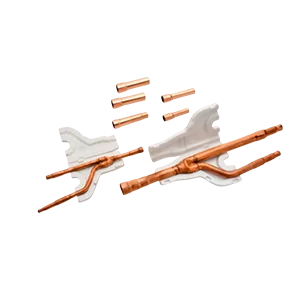

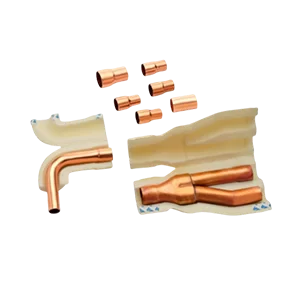

HIT Series

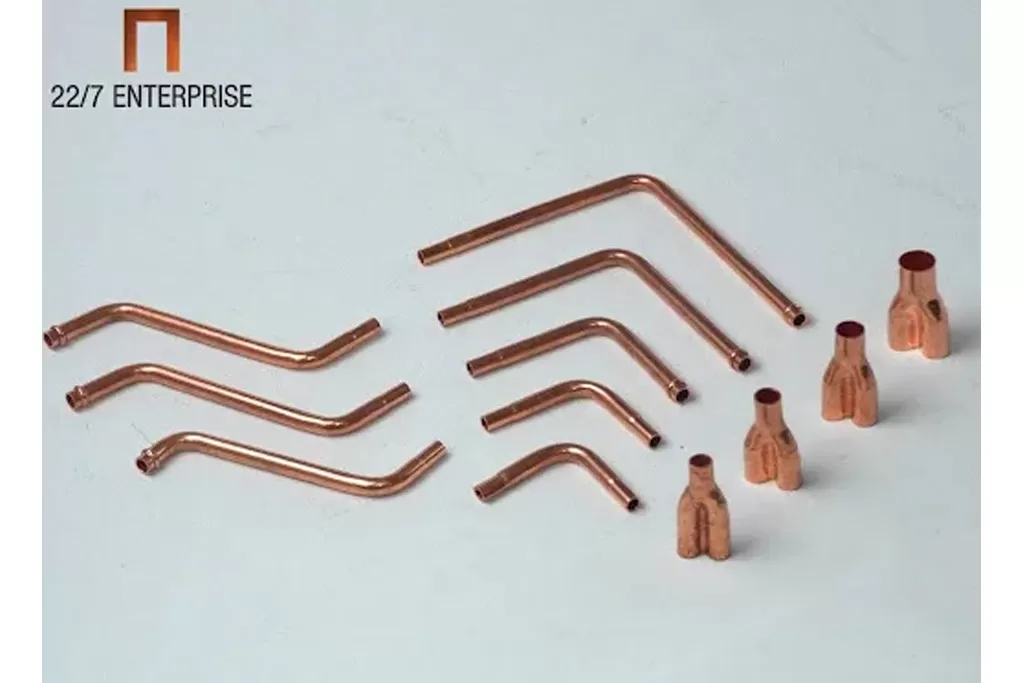

Refrigerant Branch Piping Kit for all type of VRF Systems working on R410 Refrigerant

HIT

Series

FEATURES OF HIT series

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE compliant

Robust Design

Product specification

| Pipe-A (ID) | Pipe-B (ID) | Pipe-C (ID) | Reducer (ID) | |

|---|---|---|---|---|

| Pi-E-102SNK (Gas Side) | 15.88 – 19.05 – 22.2 – 25.4 | 22.2 – 19.05 – 15.88 – 12.7 | 19.05 – 15.88 – 12.7 | |

| Pi-E-102SNK (Liquid Side) | 9.52 – 12.7 | 9.52 – 6.35 | 9.52 – 6.35 | 9.52 ID X 6.35 OD – 1 Nos |

| Pi-E-162SNK (Gas Side) | 28.58 – 25.4 | 22.2 – 25.4 – 28.58 | 22.2 – 19.05 – 15.88 – 12.7 | 28.58 OD X 25.4 ID X 22.2 ID X 19.05 ID X 15.88 ID X 12.7 ID – 1 Nos |

| Pi-E-162SNK (Liquid Side) | 12.7 | 12.7 – 9.52 | 12.7 – 9.52 – 6.35 | 9.52 ID X 6.35 OD – 1 Nos |

| Pi-E-242SNK (Gas Side) | 28.58 – 25.4 | 22.2 – 25.4 – 28.58 | 22.2 – 19.05 – 15.88 – 12.7 | 28.58 OD X 25.4 ID X 22.2 ID X 19.05 ID X 15.88 ID X 12.7 ID – 1 Nos |

| Pi-E-242SNK (Liquid Side) | 15.88 | 19.05 – 15.88 – 12.7 – 9.52 | 15.88 – 12.7 – 9.52 – 6.35 | 28.58 OD X 25.4 ID X 22.2 ID X 19.05 ID X 15.88 ID X 12.7 ID – 1 Nos |

| Pi-E-302SNK (Gas Side) | 38.1 – 31.75 | 31.75 – 38.1 | 28.58 | 28.58 OD X 25.4 ID X 22.2 ID X 19.05 ID X 15.88 ID X 12.7 ID – 1 Nos 31.75 OD X 28.58 ID X 25.4 ID X 22.2 ID – 1 Nos 38.1 OD x 34.93 ID – 1 Nos |

| Pi-E-302SNK (Liquid Side) | 19.05 – 22.2 | 22.2 – 19.05 – 15.88 – 12.7 – 9.52 | 19.05 – 15.88 – 12.7 – 9.52 – 6.35 | 9.52 ID X 6.35 OD – 1 Nos |

OUR Products

Universal

Branch Pipe

Precision-engineered universal branch pipe ensuring cross-OEM compatibility and leak-proof VRF connections.

View Details

DA

Series

Precision-engineered joints and fittings designed for performance in DA Series VRF/VRV applications.

View Details

ME

Series

Reliable copper fittings engineered to meet ME Series network specifications.

View Details

MI

Series

Durable refnet joints and branch pipes crafted for reliability in MI systems.

View Details

TA

Series

Precision TA Headers and refrigerant distributors for fit in SMMS & TA Header Series

View Details

GR

Series

Specialized fittings offering corrosion resistance and leak-proof integrity for GR heat recovery systems.

View Details

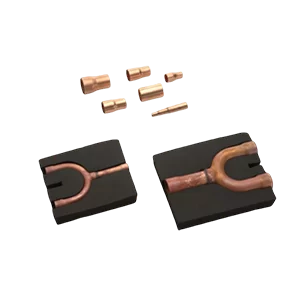

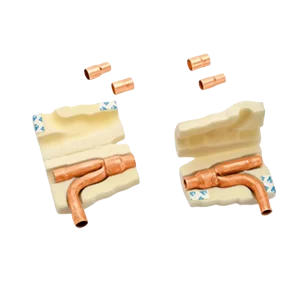

BSR

Series

Pre-insulated Branch Piping Kits for streamlined, error-free installation across OEM VRF platforms.

View Details

LG

Series

Compatible copper Y-joints and distributors meeting LG Multi V system standards.

View Details

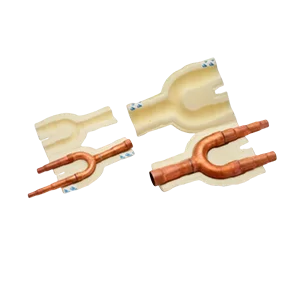

HIT

Series

Custom-tooled fittings and joints ensuring optimal compatibility for HIT Series.

View Details

HAE

Series

Robust VRF Refrigerant Branch Piping to handle pressure and demands of HAE units.

View Details

CL

Series

Precision Copper REF Joints and assemblies engineered for operation in CL conditioning systems.

View Details

LNX

Series

Certified fittings and Copper Branch Pipe systems meeting specs for LNX VRF.

View Details

PNS

Series

Accurately machined joints and pipes deliver reliability for PNS ECOi and U-Series VRF.

View Details

TRN

Series

High-performance Copper Y Fittings and piping kits engineered with TRN Series VRF systems.

View Details

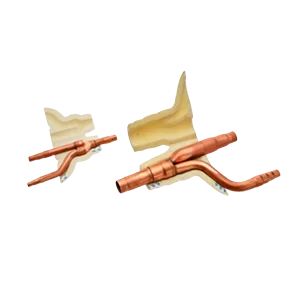

VRF Y

Joint

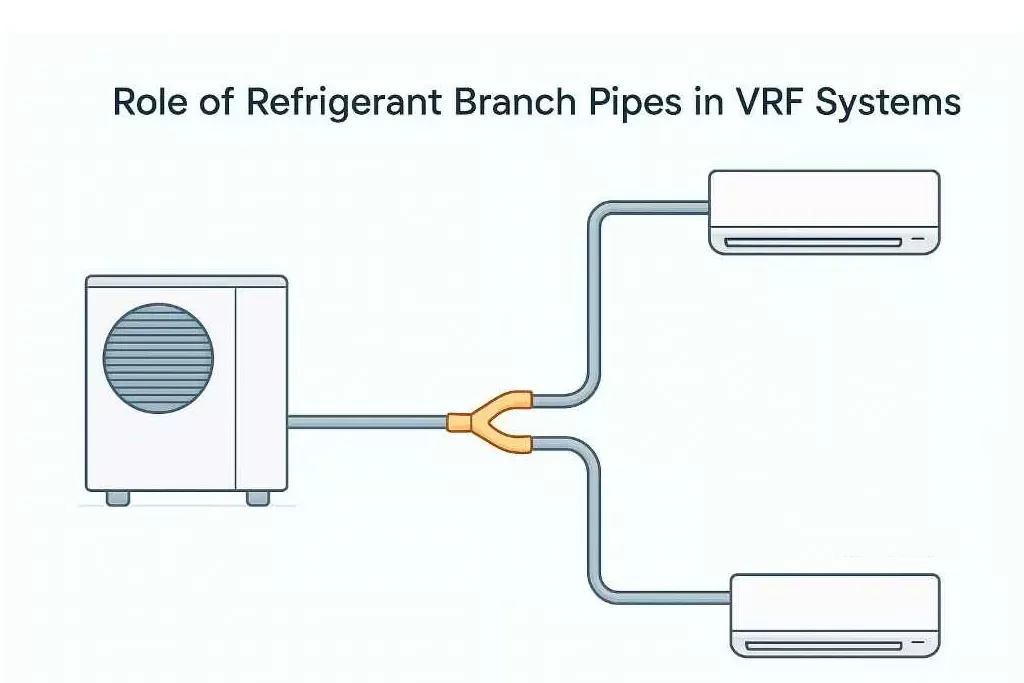

Core VRF Y joint ensuring balanced, turbulence-free refrigerant distribution for peak efficiency.

View Details

VRF Branch

Piping

All-in-one VRF refrigerant branch piping simplifying sourcing from one trusted supplier.

View Details

VRF Refrigerant

Branch Piping

Precision routing for multi-zone VRF system distribution.

View Details

SAM

Headers

OEM-specific SAM Headers and distribution joints ensure refrigerant management in DVM S systems.

View Details

TA

Headers

Precision TA Headers and refrigerant distributors for fit in SMMS and Daiseikai series.

View Details

Customized

Headers

Bespoke Customized Header assemblies designed to meet system layouts and multi-port requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The precision of the HIT Series joints drastically reduced our on-site brazing time and eliminated callbacks for leaks.

Project Manager, Mechanical Contracting Firm,

UAEFor our high-rise projects, we trust 227 Enterprise for consistent quality and pressure performance.

Chief Engineer, Property Development,

SingaporeTheir compliant documentation and product reliability simplify our procurement for international projects.

Procurement Head, MEP Consultancy,

Saudi ArabiaThe universal fit of the HIT Series is a revolution for our service team that helped maintaining multiple VRF brands.

Service Director, HVAC Facility Management,

IndiaUsing these kits has directly improved the overall energy efficiency metrics of our installed systems.

Sustainability Consultant, Green Building Firm,

UKOur Blogs

FAq's

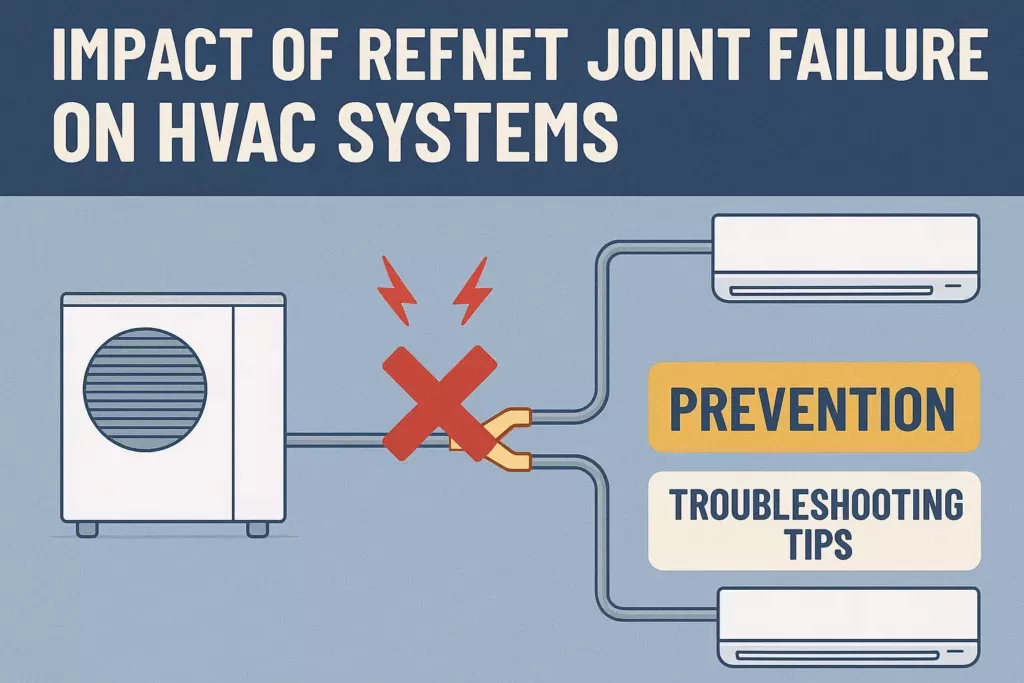

What is the primary purpose of VRF refrigerant branch pipe?

It divides the refrigerant of one outdoor unit into multiple indoor units to be able to control one zone independently. That specific flow will assist in maintaining the pressure of the system in equilibrium, allow you to both heat or cool efficiently at once and drive the entire VRF system towards the most energy savings possible.

What is the reason why VRF refrigerant pipes are made of copper?

Copper is an excellent conductor of heat and therefore, it conducts heat well, and copper does not rust thus lasts longer. It is compatible with the high pressures of modern refrigerants and this makes it efficient, prevents leaks and provides you with the reliable performance over the years in those complex, expensive VRF systems.

Do HIT Series work with all of the large VRF brands?

Yep. Their multi-step design allows them to fit various standard pipe sizes hence making them universal. It means that contractors are able to apply them to numerous projects, which are easier to hold in stock and which will always be in the right place.

What is the 5.2 Mpa (52 Bar) pressure test assured?

The test in that factory confirms that the joint is capable of taking pressures much higher than it will in normal operation. It demonstrates that the joint is watertight, very robust and secure. The test prevents the expensive failures and downtimes in the field, and installer and owners are assured that the product will be durable.

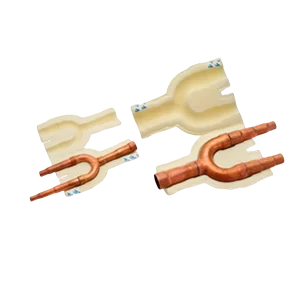

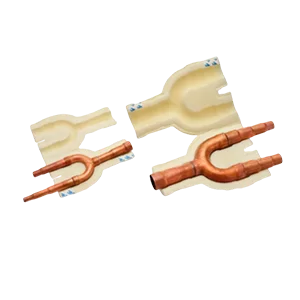

What is the benefit of the pre-installed insulation in installation?

The XLPE insulation, which is fitted to the factory as fire-grade is laser-cut to fit perfectly. It prevents condensation, eliminates on-site insulation, accelerates installation and provides consistent heat protection without any gaps. That exact fit appears clean and contributes to the overall system remaining energy efficient.

What are some of the important installation instructions of these branch joints?

To avoid oxidation and copper oxide, first use nitrogen during brazing. Ensure that the pipes are well supported and sloped in order to allow oil to be returned. Use a dry, clean and tight method. The next step is to check the entire circuit functionality by running a test pressure decay and vacuum test once installed.

Are these joints compatible with the new low-GWP refrigerants?

Of course. Constructed of premium copper and pressure tested, the HIT Series is compatible with contemporary low-GDP refrigerants such as R-32. Its powerful design addresses the demands of such environmentally friendly coolants to ensure the safety and future-proof performance is reliable.

What are the certifications of the HIT Series?

What are the certifications of the HIT Series?

What model number do you choose?

It is subject to the size of the system (tonnage), the number of branches within the system (indoor), and the size of the liquid and gas pipes that you require. Review VRF specifications of the project and review our comprehensive datasheets. Our engineering support team would also assist you in the choice of the model that you require.

How do you ensure quality assurance of your leaks?

We select super pure copper, perform automated nitrogen purify brazing, and perform a 100 per cent helium mass-spectrometer test to identify small leaks and complete with 5.2 100 gpa hydrostatic pressure test. This is a multi-stage inspection that ensures that all the joints are leakproof during the production phase all the way to your location.