VRF

- Universal Branch Pipe

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

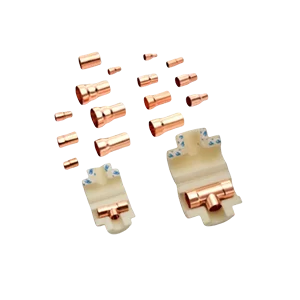

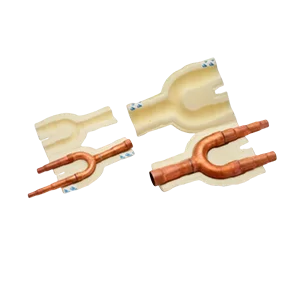

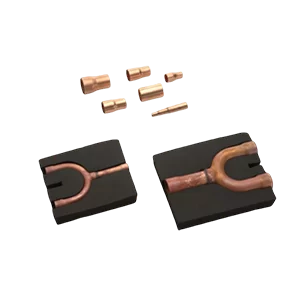

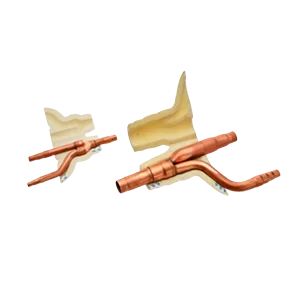

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

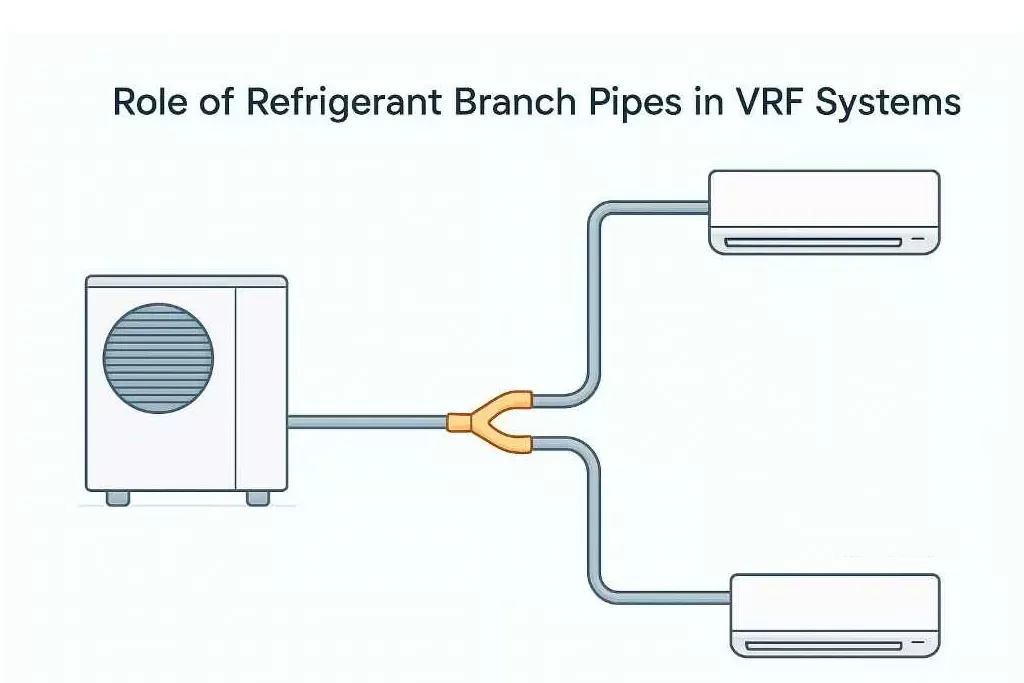

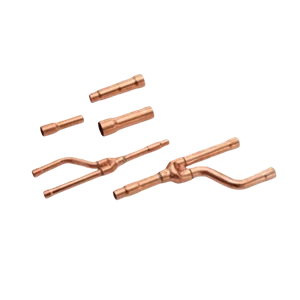

- VRF Y Joint

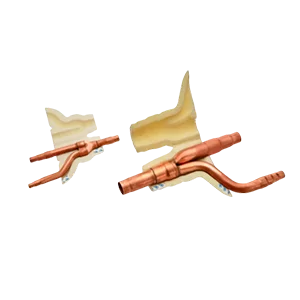

- VRF Branch Piping

- VRF Refrigerant Branch Piping

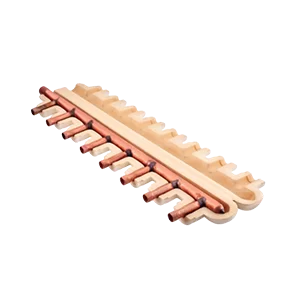

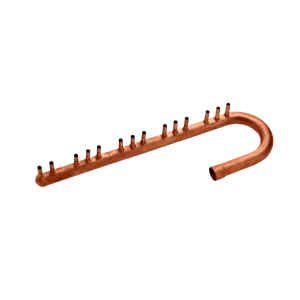

Headers

- SAM Headers

- TA Headers

- Customized Headers

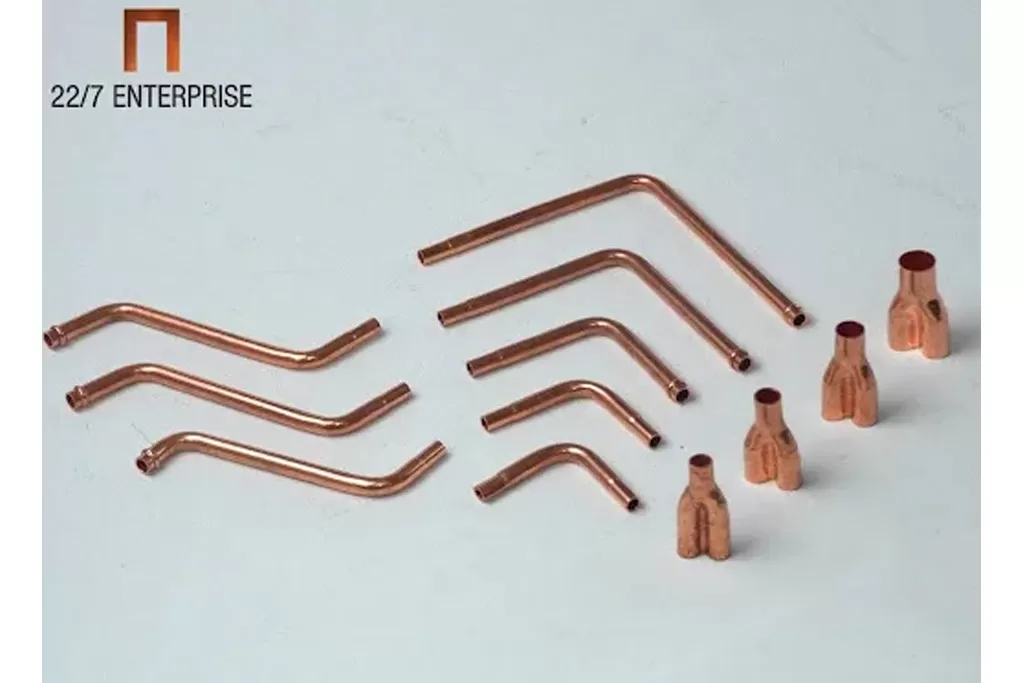

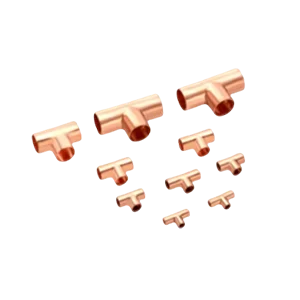

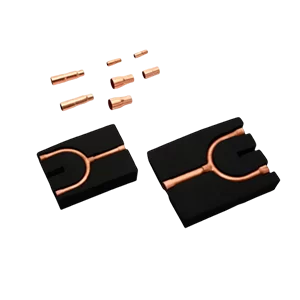

Copper Components

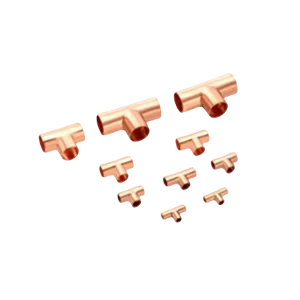

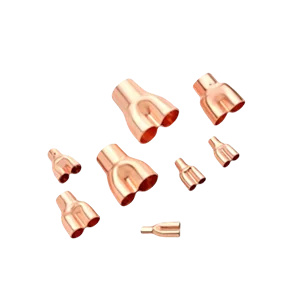

- Copper Compression T Fitting

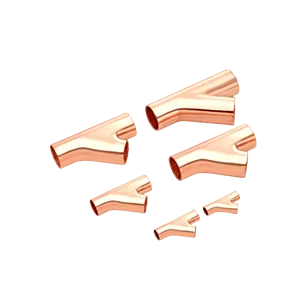

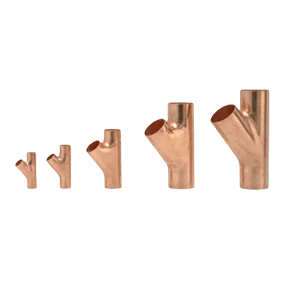

- Copper Y Fitting

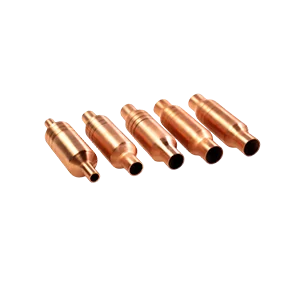

- Strainers

- Mufflers

- Stubs

- Commercial Tee's

- Copper Tee Joint

- Y-Type Distributors

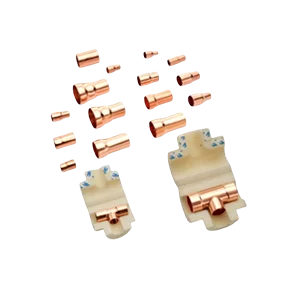

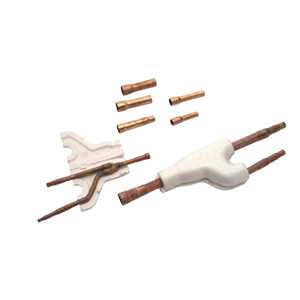

- Unbrazed U & Y Fittings

- Copper Y-Joint

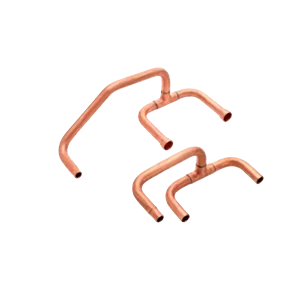

- Tubular Assemblies

Customized insulation

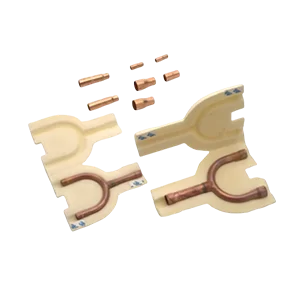

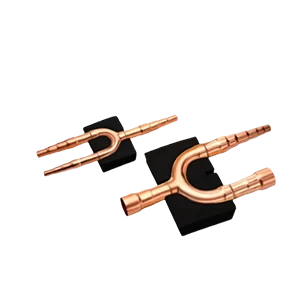

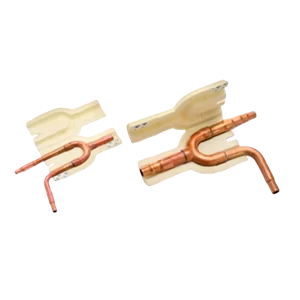

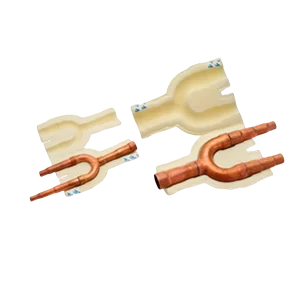

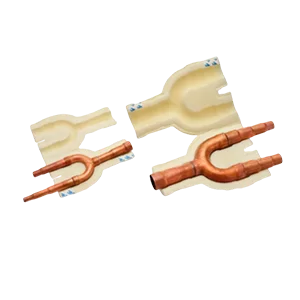

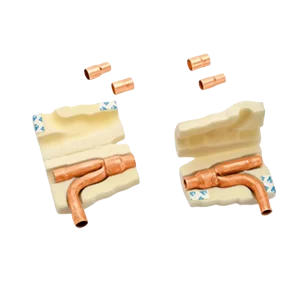

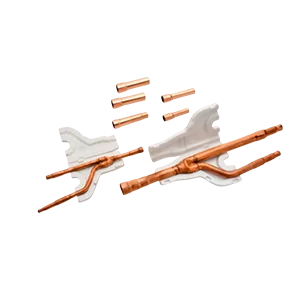

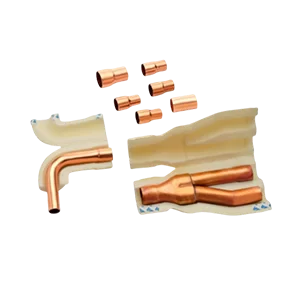

BSR Series

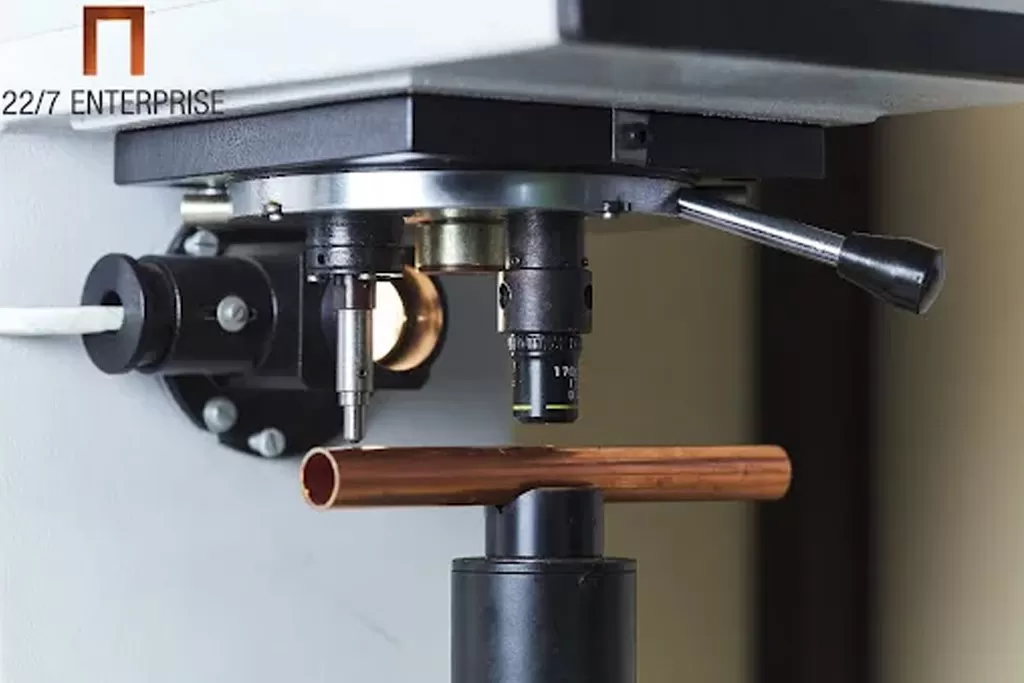

Precision-Engineered Refrigerant Branch Piping Kit for All VRF Systems Using R410A Refrigerant

BSR

Series

FEATURES OF BSR series

Easy to Install

Pressure Tested at 5.2 MPA

100% leak proof

ROHS & CE compliant

Robust Design

Product specification

| Model No | Pipe A (ID) | Pipe-B (ID) | Pipe-C (ID) |

|---|---|---|---|

| Pi-BVRJ-5-6-I (Gas Side) | 12.07 – 15.88 – 19.05 | 19.05 – 15.88 – 12.7 | 19.05 – 15.88 – 12.7 |

| Pi-BVRJ-5-6-I (Liquid Side) | 6.35 – 9.52 – 12.7 | 12.7 – 9.52 – 6.35 | 12.7 – 9.52 – 6.35 |

| Pi-BVRJ-8-19-I (Gas Side) | 19.05 – 22.22 – 28.58 – 31.75 | 31.75 – 28.58 – 22.22 – 19.05 – 15.88 – 12.7 | 31.75 – 28.58 – 22.22 – 19.05 – 15.88 – 12.7 |

| Pi-BVRJ-8-19-I (Liquid Side) | 9.52 – 12.7 – 15.88 | 15.88 – 12.7 – 9.52 – 6.35 | 15.88 – 12.7 – 9.52 – 6.35 |

| Pi-BVRJ-24-63-I (Gas Side) | 41.28 – 34.93 | 34.93 – 28.58 – 22.22 – 19.05 – 15.88 – 12.7 | 34.93 – 41.28 |

| Pi-BVRJ-24-63-I (Liquid Side) | 12.7 – 15.88 – 19.05 – 22.22 | 19.05 – 15.88 – 12.7 – 9.52 | 22.22 – 19.05 – 15.88 – 12.7 |

| Pi-BVRJ-24-63-O (Gas Side) | 28.58 – 34.93 – 41.28 | 34.93 – 28.58 | 41.28 – 34.93 – 28.58 |

| Pi-BVRJ-24-63-O (Liquid Side) | 15.88 – 19.05 | 19.05 – 15.88 – 12.7 | 19.05 – 15.88 |

OUR Products

Universal

Branch Pipe

Precision-engineered universal branch pipe ensuring cross-OEM compatibility and leak-proof VRF connections.

View Details

DA

Series

Refrigerant Branch Piping Kits for VRV / VRF Systems Operating with R410 Refrigerant.

View Details

ME

Series

Reliable copper fittings engineered to meet ME Series network specifications.

View Details

MI

Series

Durable refnet joints and branch pipes crafted for reliability in MI systems.

View Details

TA

Series

Refrigerant Branch Piping Kits for VRF Systems Operating with R410 Refrigerant

View Details

GR

Series

VRF Y Branch Refrigerant Distribution Kits for VRV / VRF Systems Operating with R410.

View Details

BSR

Series

VRF Refrigerant Branch Piping Kits for VRF Air Conditioning Systems Compatible with R410A Refrigerant.

View Details

HAE

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

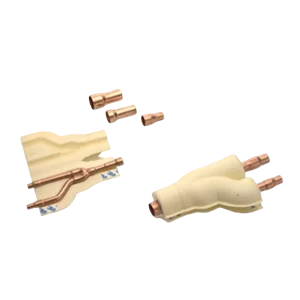

CL

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

LNX

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

MHI

Series

VRF Refrigerant Branch Piping Kit for VRF Air Conditioning Systems Compatible with R410 Refrigerant

View Details

SAM

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

PNS

Series

VRF Y Joints for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

TRN

Series

VRF Y Branch for VRF Air Conditioning Systems Compatible with R410 Refrigerant.

View Details

VRF Y

Joint

Precision Manufactured VRF Y Joints for Optimal Laminar Refrigerant Flow and Efficient System Performance.

View Details

VRF Branch

Piping

All-in-one VRF refrigerant branch piping simplifying sourcing from one trusted supplier.

View Details

VRF Refrigerant

Branch Piping

Manufactured for Optimal Refrigerant Flow Distribution in VRF Systems Working on R410 Refrigerant.

View Details

SAM

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

TA

Headers

Precision Manufactured VRF Copper Header for VRF Systems Compatible with R410 Refrigerant.

View Details

Customized

Headers

Tailor-Made VRF Copper Header Manufacturing as per Project Requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

Installation time on a large hotel installation was reduced by 30 percent using 227 pre-insulated, multi-step BSR joints shaved, and we had no rework.

HVAC Contractor,

UAE Project Manager.As a consultant, I select 227 Enterprise due to the fact that it is certified, traceable, and eliminates the chances of subsystems collapsing.

Engineering Consultancy,

Saudi Arabia, MEP Director.Their BSR kits, which are determined by CE standards, ensured that our project met all international requirements of a global customer, and we were not late.

Head of Procurement, MEP Consultancy,

Saudi Arabia.The joints provided an ideal refrigerant ratio which made the VRF system we fitted very energy-saving.

Technical Head, system integrator,

IndiaIn the case of OEM stuff, copper joints of 227 are best in remaining consistent and accurate and thus our units are good.

Quality Assurance Manager, HVAC Company,

South Asia.Our Blogs

FAq's

What is the largest win with the BSR Series Multi- Step design?

This is because in essence, one joint is able to connect various sizes of pipes, thus reducing the number of brazing points that you need to complete on the field. That saves time, reduces expenses and prevents the leaks of popping up- and the entire VRF system will last longer and perform better in the hands of installers and owners.

Do the 227 Enterprise BSR Series really fit with all VRF brands?

Yeah, for sure. The construction of these joints is such that they fit all the large R410a VRF systems in the market. That is to say that the contractors and designers can maintain their parts list at a level that is extremely simple and still achieve a perfect fit regardless of the OEM they are utilizing.

How does the insulation that is installed prevent condensation and sweating?

The insulation (UV-stabilized fire-grade XPLE or NBR) is immediately applied to serve as an all-time heat shield. In that manner the chill pipe does not get in contact with the warm and humid outside air and you do not have all of those nasty droplets that can cause ceilings to mess up or mould.

What is that 100 percent leak proof guarantee and what is their test?

All the joints are hammered under a hard factory pressure test of 5.2 That will show the seal is forever, and you will never find any leakage of refrigerant when you put it on. Maintains the lean and mean system.

What is the reason we are interested in ROHS and CE of the VRF fittings?

ROHS will ensure the parts are free of the nasty chemicals and everyone is safer. CE implies that the product satisfies all the rigid EU health, safety and performance boxes. It is normally a requirement in projects abroad, you are the best of the best and it will be much easier to get approvals on behalf of the crew.

What are the advantages of the branch piping kits to the entire VRF system?

The Y-joints are made with accuracy such that every indoor unit receives the appropriate quantity of refrigerant. That prevents some places being made either too cold or too hot, no over- or under-feeding, making all the zones reach their set point quicker and more easily.

What is the life expectancy of BSR Series copper joints?

They consist of high grade phosphorous de-oxidized copper and wrapped in tough insulation, thus they are designed to last the entire 15-20 years life cycle of a VRF system. They are able to withstand corrosion and continue to work well at the usual conditions and so they provide a maintenance free, reliable service alongside the main components.

Can I get custom-configured BSR Branch Piping Kits for a specific project layout?

Absolutely! We are a high-end producer, thus we can drop assembled kits or completely modify components to your specific project setup and requirements. That reduces welding on the building-site and prevents errors on an original design.

How does using BSR Series kits impact project timeline and warranty?

BSR Series kits are quicker to assemble and the warranty is kept clean. Since you reduce the number of site brazing and assembly errors, you become quicker to complete, and the certificates of pressure-testing reinforce the credibility, and thus you have fewer returns, and a good warranty to installers and constructors. It aids in safeguarding the image of the project and renders the process of its delivery easy.

Where do you get the technical specifications or get assistance on your project?

All the specifications and CAD images are available to be forwarded upon request. We have a tech support team that can assist you in choosing the correct product, compatibility with other systems, and guide you in the process of installation. All you need to do is to send us a call or an email and we will provide you with fast and professional assistance according to your project.