VRF

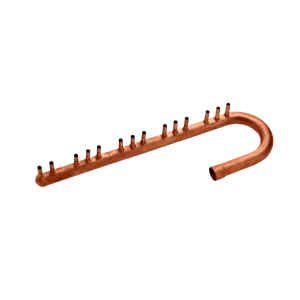

- Universal Branch Pipe

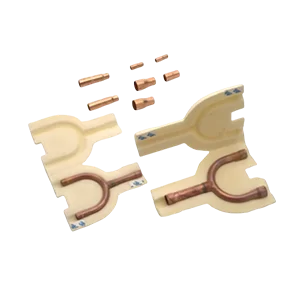

- DA Series

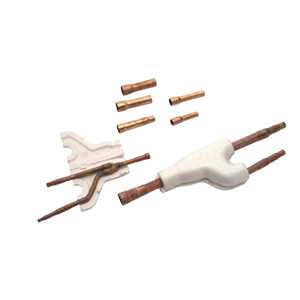

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

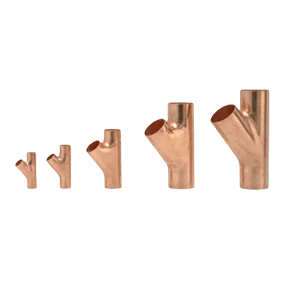

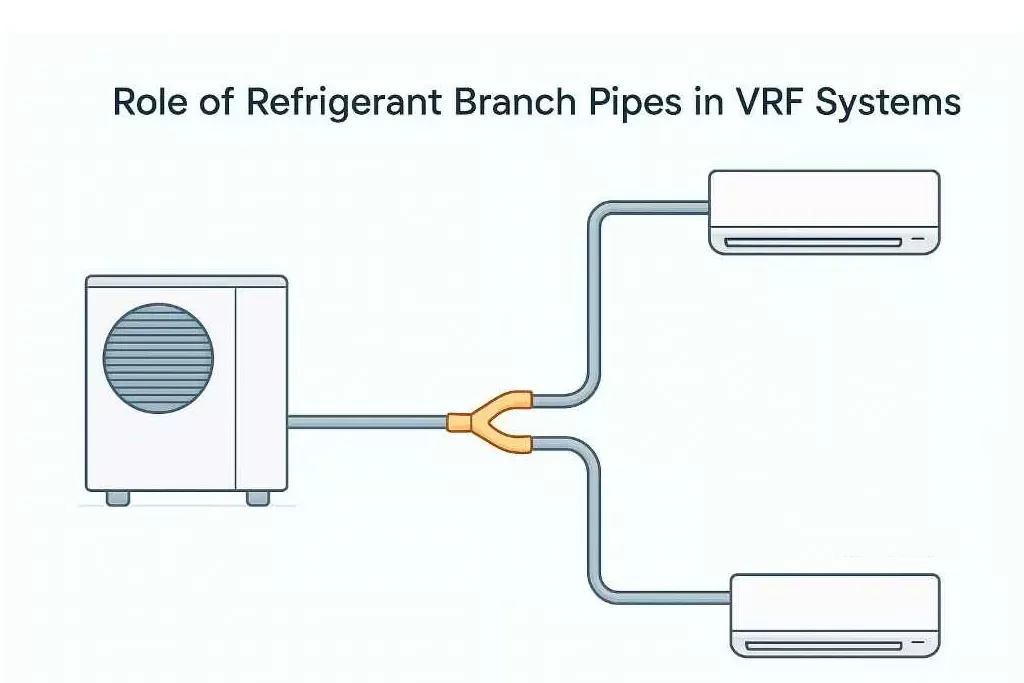

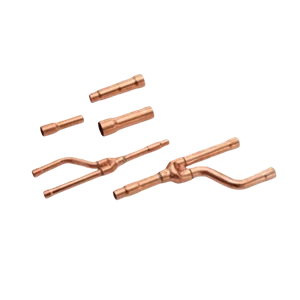

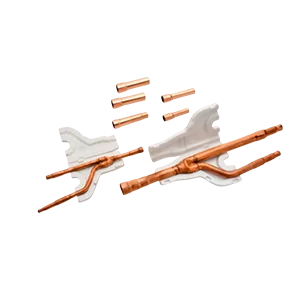

- VRF Y Joint

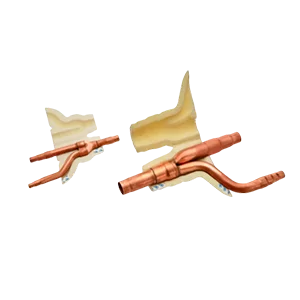

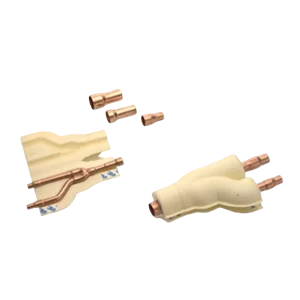

- VRF Branch Piping

- VRF Refrigerant Branch Piping

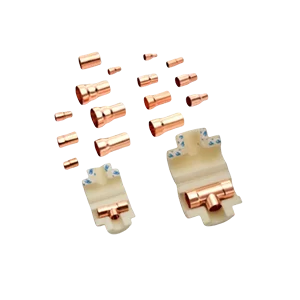

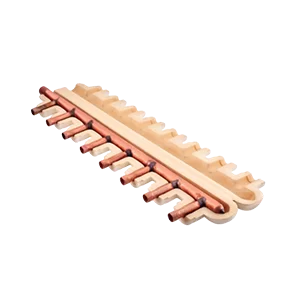

Headers

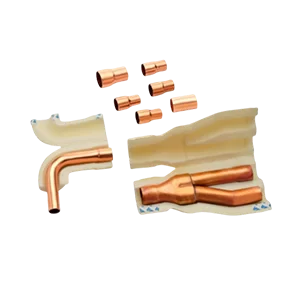

- SAM Headers

- TA Headers

- Customized Headers

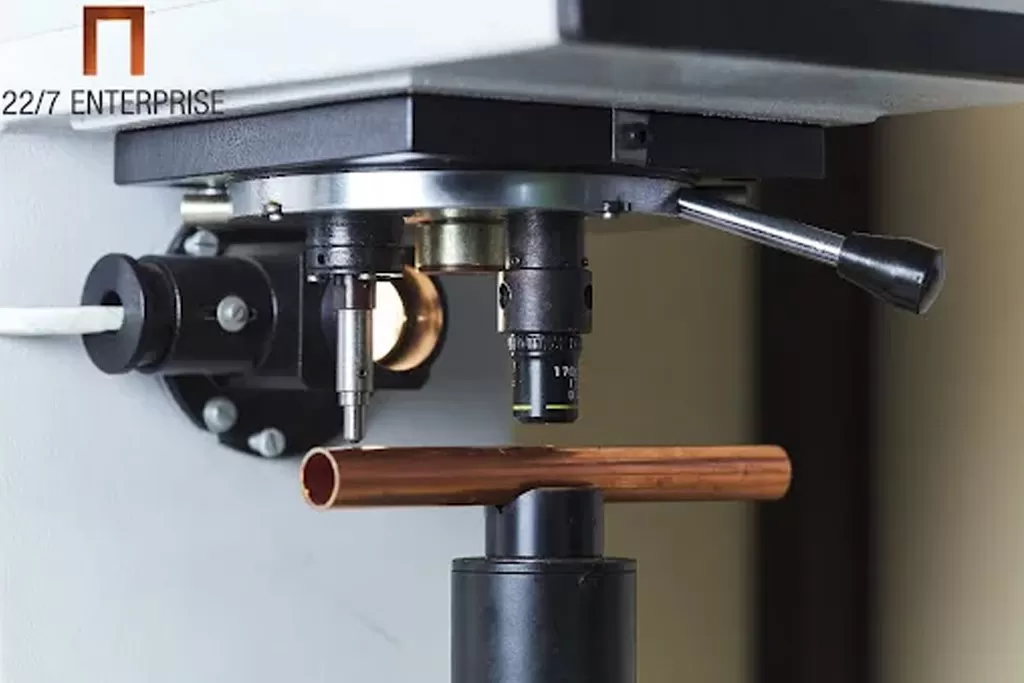

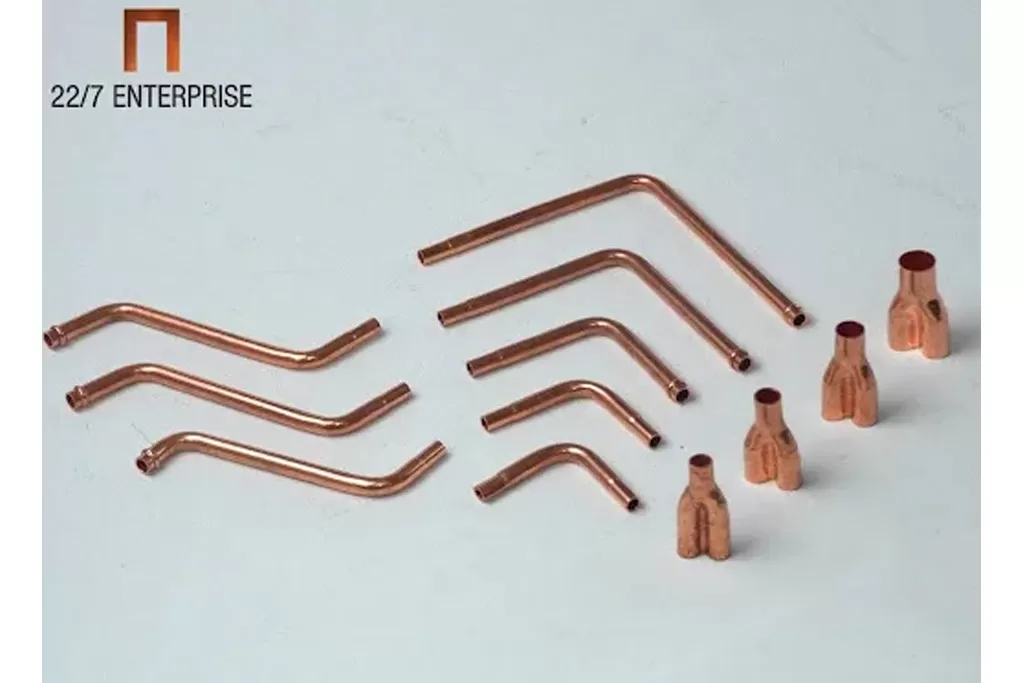

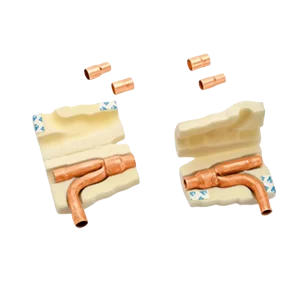

Copper Components

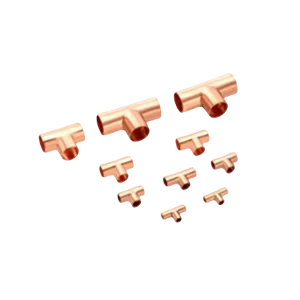

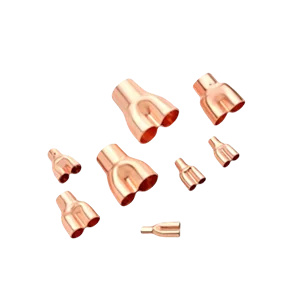

- Copper Compression T Fitting

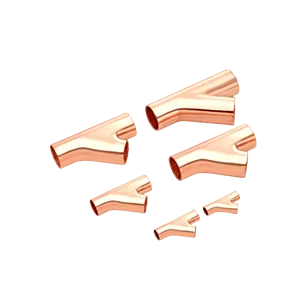

- Copper Y Fitting

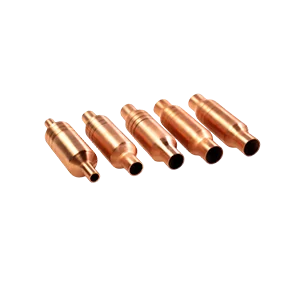

- Strainers

- Mufflers

- Stubs

- Commercial Tee's

- Copper Tee Joint

- Y-Type Distributors

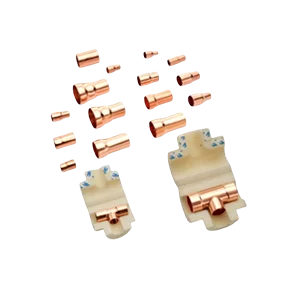

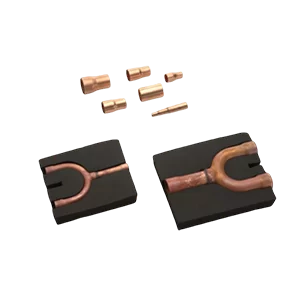

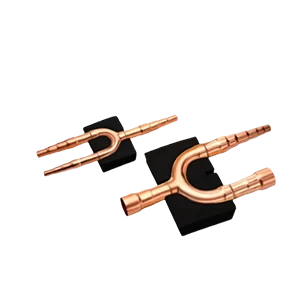

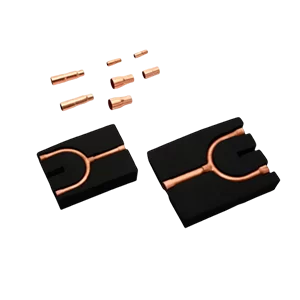

- Unbrazed U & Y Fittings

- Copper Y-Joint

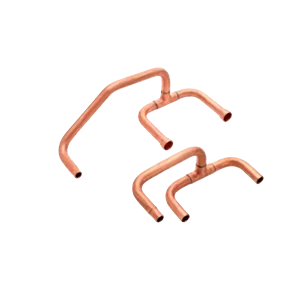

- Tubular Assemblies

Customized insulation

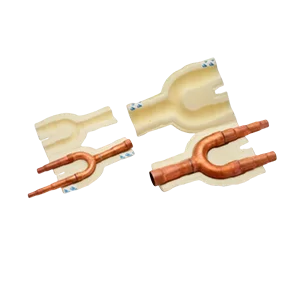

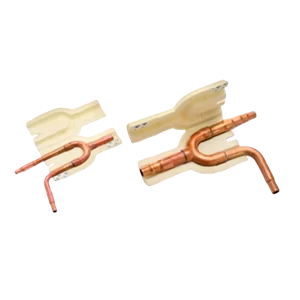

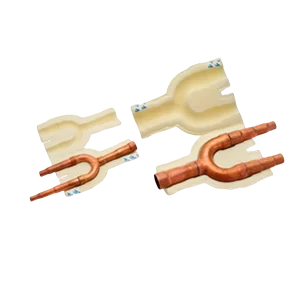

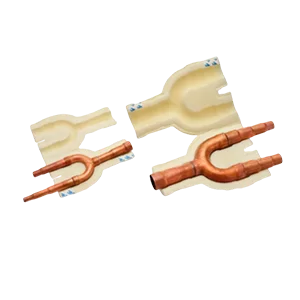

DA Series With XLPE Insulation

Premium VRF Copper Joints with UV‑Stabilized Fire Grade XLPE Insulation

The UV‑stabilized Fire Grade XLPE insulation prevents sweating, ensures long‑term thermal stability, and offers excellent moisture and chemical resistance. Its closed‑cell structure maintains consistent insulation performance, delivering reliable, long‑lasting operation for advanced HVAC installations.

XLPE

Insulation

FEATURES OF DA Series With XLPE Insulation

Easy installation design

FR Grade

RoHS & CE compliant

Chemical & Abrasion Resistant

UV-protected

Product specification

| Pipe-A | Pipe-B | Pipe-C | |

|---|---|---|---|

| Pi-KHRP-22T (Gas Side) | 12.7 (1/2) – 15.88 (5/8) – 19.05 (3/4) | 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-22T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35(1/4) | 9.52 (3/8) – 6.35(1/4) |

| Pi-KHRP-33T (Gas Side) | 22.22 (7/8) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-33T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35 (1/4) | 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-72T (Gas Side) | 31.75 (11/4) -28,58 ( 11/8) – 25.4 (1) | 25.4 (1) – 19.05(3/4) – 15.88 (5/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-72T (Liquid Side) | 15.81 (5/8) – 12.7 (1/2) | 12.7 (1/2) – 9.52 (3/8) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-73T (Gas Side) | 38.10 (11/2) – 31.75 (11/4) | 31.75 (11/4) – 28.58 (11/8) – 25.4 (1) | 25.4 (1) – 19.05 (3/4) – 15.88 (5/8) |

| Pi-KHRP-73T (Liquid Side) | 15.88 (5/6) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) |

OUR Products

Universal

Branch Pipe

Precision-engineered universal branch pipe ensuring cross-OEM compatibility and leak-proof VRF connections.

View Details

DA

Series

Precision-engineered joints and fittings designed for performance in DA Series VRF/VRV applications.

View Details

ME

Series

Reliable copper fittings engineered to meet ME Series network specifications.

View Details

MI

Series

Durable refnet joints and branch pipes crafted for reliability in MI systems.

View Details

TA

Series

Precision TA Headers and refrigerant distributors for fit in SMMS & TA Header Series

View Details

GR

Series

Specialized fittings offering corrosion resistance and leak-proof integrity for GR heat recovery systems.

View Details

BSR

Series

Pre-insulated Branch Piping Kits for streamlined, error-free installation across OEM VRF platforms.

View Details

LG

Series

Compatible copper Y-joints and distributors meeting LG Multi V system standards.

View Details

HIT

Series

Custom-tooled fittings and joints ensuring optimal compatibility for HIT Series.

View Details

HAE

Series

Robust VRF Refrigerant Branch Piping to handle pressure and demands of HAE units.

View Details

CL

Series

Precision Copper REF Joints and assemblies engineered for operation in CL conditioning systems.

View Details

LNX

Series

Certified fittings and Copper Branch Pipe systems meeting specs for LNX VRF.

View Details

PNS

Series

Accurately machined joints and pipes deliver reliability for PNS ECOi and U-Series VRF.

View Details

TRN

Series

High-performance Copper Y Fittings and piping kits engineered with TRN Series VRF systems.

View Details

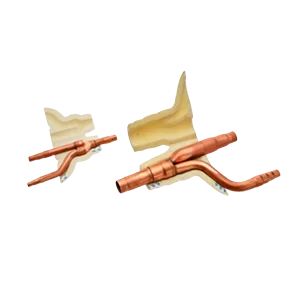

VRF Y

Joint

Core VRF Y joint ensuring balanced, turbulence-free refrigerant distribution for peak efficiency.

View Details

VRF Branch

Piping

All-in-one VRF refrigerant branch piping simplifying sourcing from one trusted supplier.

View Details

VRF Refrigerant

Branch Piping

Precision routing for multi-zone VRF system distribution.

View Details

SAM

Headers

OEM-specific SAM Headers and distribution joints ensure refrigerant management in DVM S systems.

View Details

TA

Headers

Precision TA Headers and refrigerant distributors for fit in SMMS and Daiseikai series.

View Details

Customized

Headers

Bespoke Customized Header assemblies designed to meet system layouts and multi-port requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The DA Series joints with XLPE insulation have drastically reduced condensation issues in our VRF projects, ensuring reliable performance.

Procurement Head, MEP Consultancy,

Saudi ArabiaAs an HVAC contractor, I appreciate the easy installation and perfect fit of 227 Enterprise’s XLPE‑insulated joints, saving time and labor.

HVAC Contractor, Commercial Construction,

UAEThe fire‑grade XLPE insulation meets our strict safety standards, making these joints our preferred choice for high‑rise buildings.

Project Manager, Real Estate Developer,

IndiaWe have sourced DA Series joints for multiple international projects; the quality, consistency and timely delivery are impressive.

Supply Chain Director, HVAC Manufacturer,

GermanyThe competitive pricing and superior moisture resistance of these XLPE‑insulated joints provide excellent value for our installations.

Engineering Manager, Facility Management Company,

USAOur Blogs

FAq's

What is XLPE insulation?

XLPE (Crosslinked Polyethylene) is a thermoset insulation material renowned for its exceptional durability and performance. Created by cross-linking polymer chains, it offers superior thermal stability, excellent moisture and chemical resistance, and high mechanical strength compared to standard polyethylene, making it the premium choice for protecting critical VRF copper joints from energy loss and condensation.

Why is XLPE insulation important for VRF systems?

VRF systems are highly efficient but require precise refrigerant temperatures. XLPE insulation is vital as it minimizes unwanted heat gain or loss in piping, maintains system efficiency, and, crucially, prevents condensation that leads to corrosion, mold, and water damage. Its durability ensures this protection lasts for the system's entire lifecycle.

What is the temperature range of DA Series XLPE insulation?

Our DA Series XLPE insulation is engineered to perform reliably in a wide temperature range from -40°C to +90°C. This ensures optimal thermal protection and physical integrity in both extreme winter conditions and high-temperature summer operations, guaranteeing consistent VRF system performance in any climate or environment.

Is the XLPE insulation fire‑resistant?

Yes, absolutely. Our insulation is specifically formulated to be Fire Retardant (FR) Grade. It is designed to inhibit the spread of flame, produce low smoke, and self-extinguish, thereby significantly enhancing the overall fire safety profile of the building's HVAC installation and complying with stringent safety standards.

How does XLPE insulation prevent sweating?

Sweating occurs when warm, humid air contacts cold piping. Our XLPE insulation features a closed-cell structure that acts as a superior vapor barrier, drastically reducing water vapor transmission. This, combined with its low thermal conductivity, keeps the outer surface temperature above the dew point, effectively eliminating condensation and its associated problems.

Is the insulation UV‑protected?

Yes, our DA Series insulation is UV-stabilized. This critical additive protects the material from degradation caused by prolonged exposure to sunlight, preventing cracking, loss of elasticity, and thermal performance decline. This makes it perfectly suitable for outdoor sections of VRF piping without requiring an additional protective jacket.

What certifications does the DA Series insulation have?

Our product is RoHS (Restriction of Hazardous Substances) and CE compliant. These certifications verify that the material is free from restricted hazardous materials and meets European health, safety, and environmental protection standards, ensuring it is safe for use and acceptable in regulated global markets.

How do I install the DA Series insulated joints?

Installation is designed for efficiency. The insulation is pre-slit and pre-shaped. Simply open the slit, wrap it snugly around the cleaned copper joint, ensure a tight seal at all seams, and then secure it permanently with compatible HVAC-grade adhesive tape to form a continuous, unbroken insulation layer.

Can I get custom sizes and shapes?

As a top-tier manufacturer, we specialize in customized solutions. We can produce XLPE insulation in any precise size, thickness, or complex shape to fit unique Y-joint configurations or specific project requirements, using our specialised dies and moulds to ensure a perfect and professional fit every time.

What is the lifespan of XLPE insulation?

Our high-grade XLPE insulation is engineered for exceptional longevity and is designed to last the entire service life of the VRF system itself. When installed correctly under standard operating conditions, its performance and protective integrity typically remain uncompromised for decades, often exceeding 20-25 years. This extended lifespan is a direct result of its cross-linked structure, which provides outstanding resistance to environmental aging, thermal stress, and physical wear, ensuring long-term reliability and delivering superior lifecycle value for your investment.