VRF

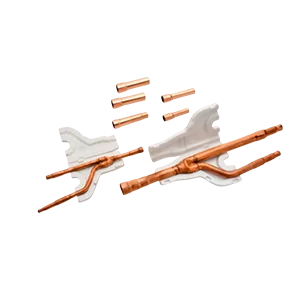

- Universal Branch Pipe

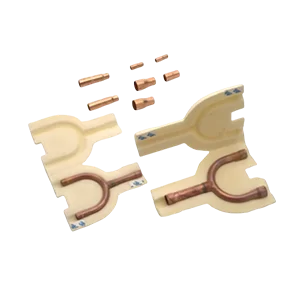

- DA Series

- ME Series

- MI Series

- TA Series

- GR Series

- BSR Series

- LG Series

- HIT Series

- HAE Series

- CL Series

- LNX Series

- MHI Series

- SAM Series

- PNS Series

- TRN Series

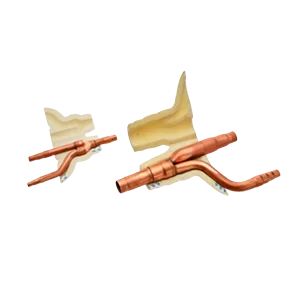

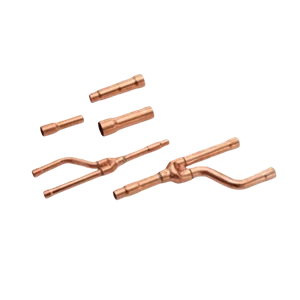

- VRF Y Joint

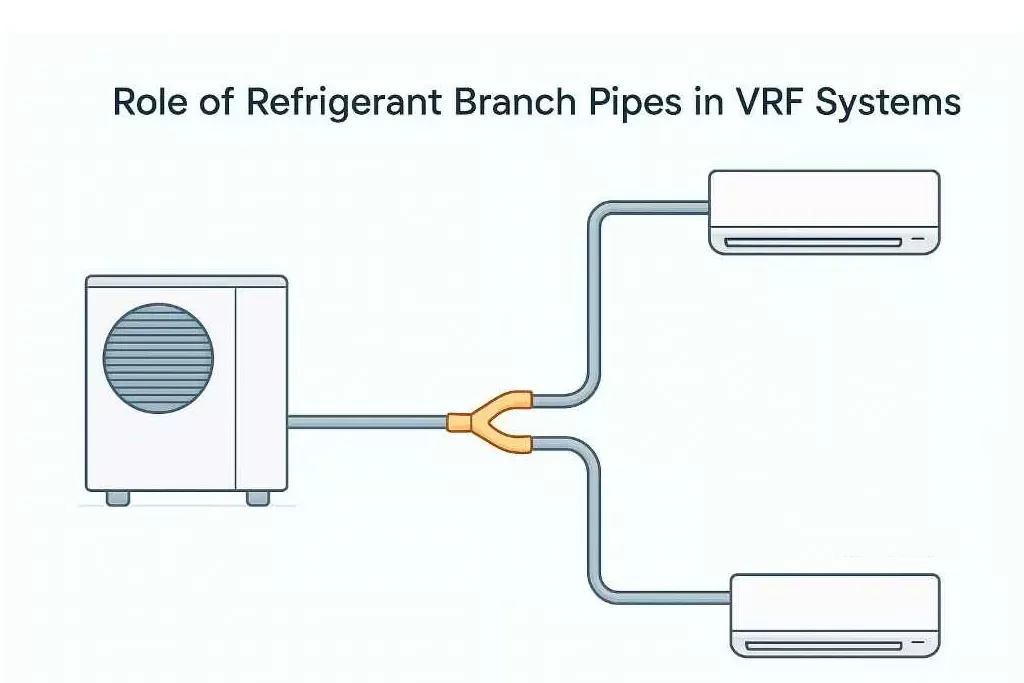

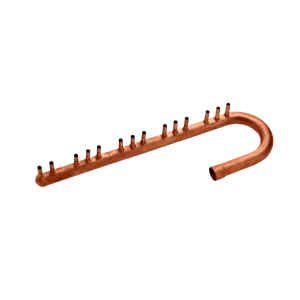

- VRF Branch Piping

- VRF Refrigerant Branch Piping

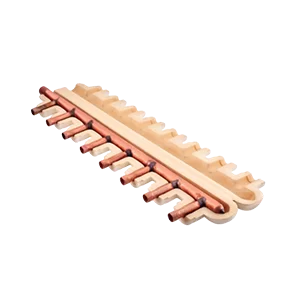

Headers

- SAM Headers

- TA Headers

- Customized Headers

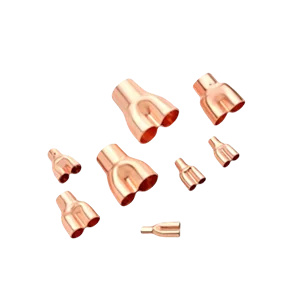

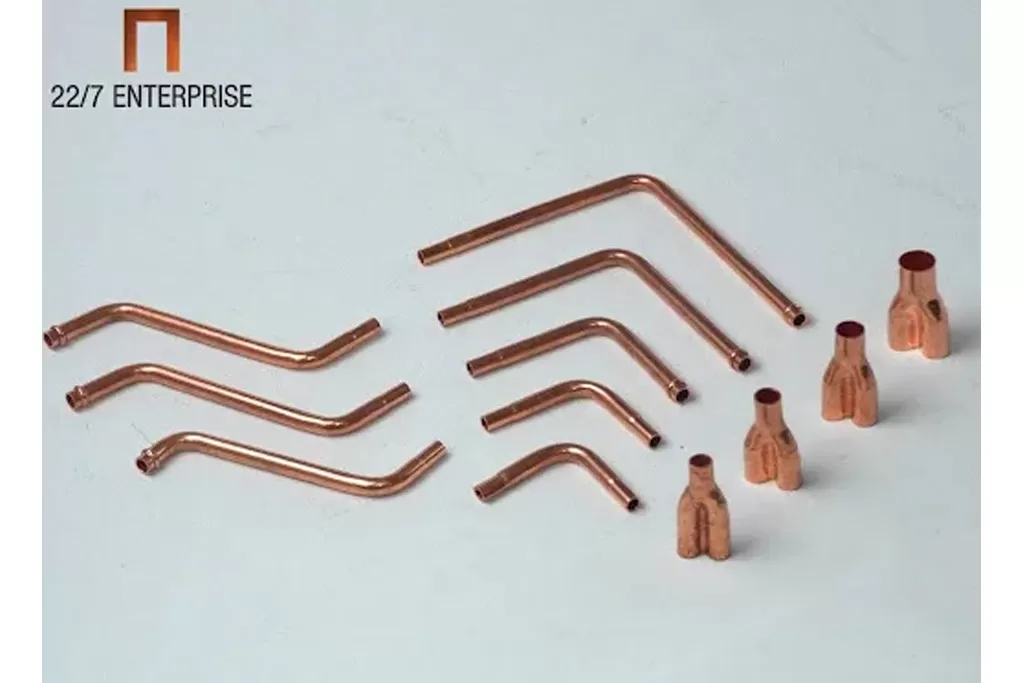

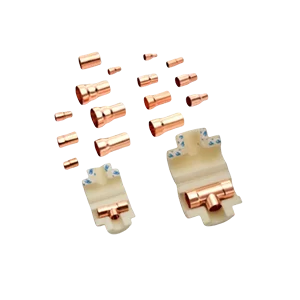

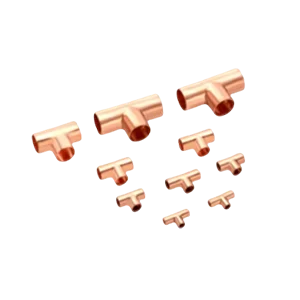

Copper Components

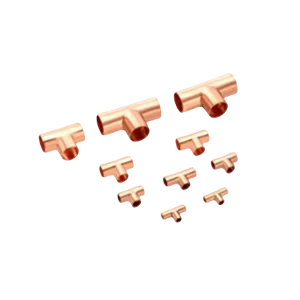

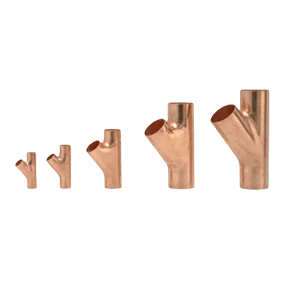

- Copper Compression T Fitting

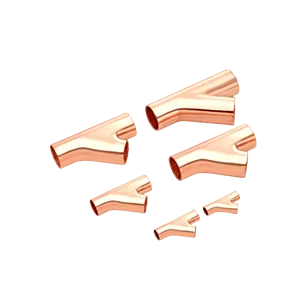

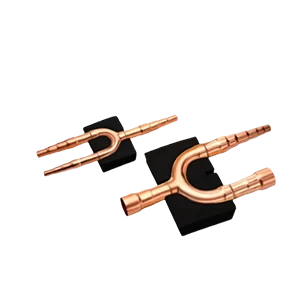

- Copper Y Fitting

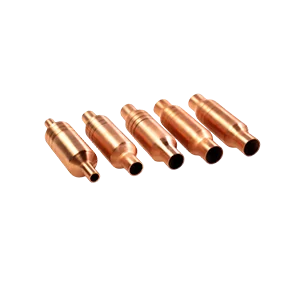

- Strainers

- Mufflers

- Stubs

- Commercial Tee's

- Copper Tee Joint

- Y-Type Distributors

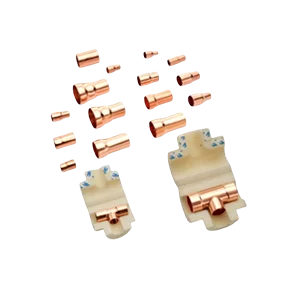

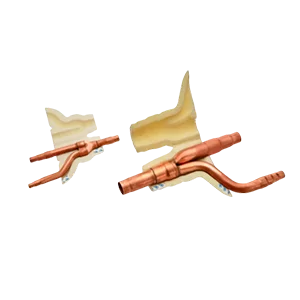

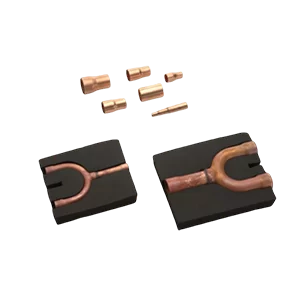

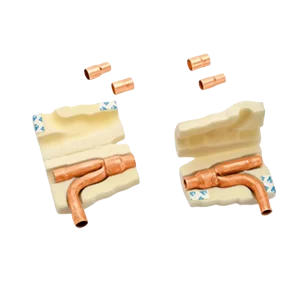

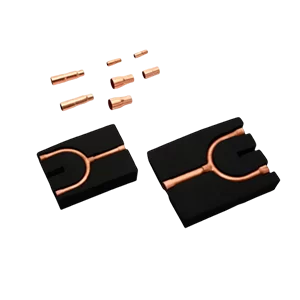

- Unbrazed U & Y Fittings

- Copper Y-Joint

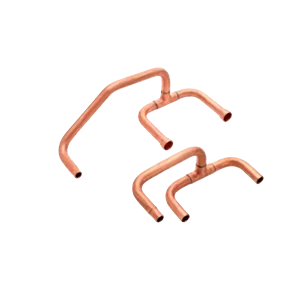

- Tubular Assemblies

Customized insulation

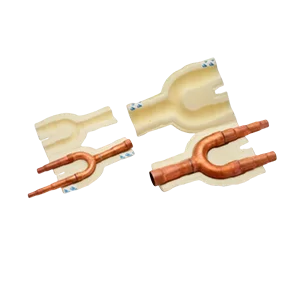

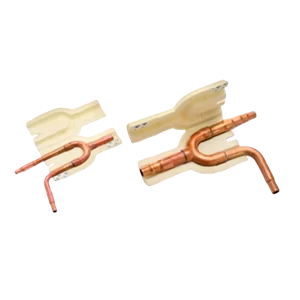

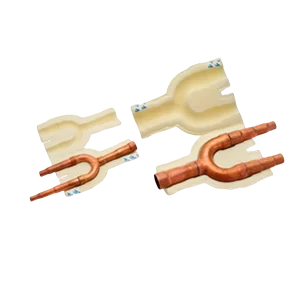

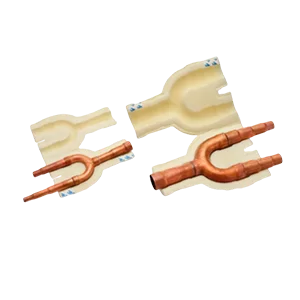

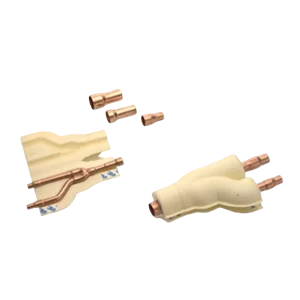

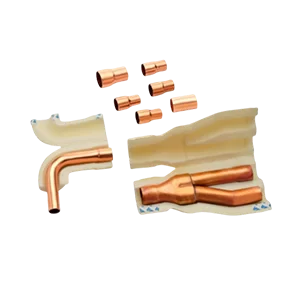

DA Series With Eps Insulation

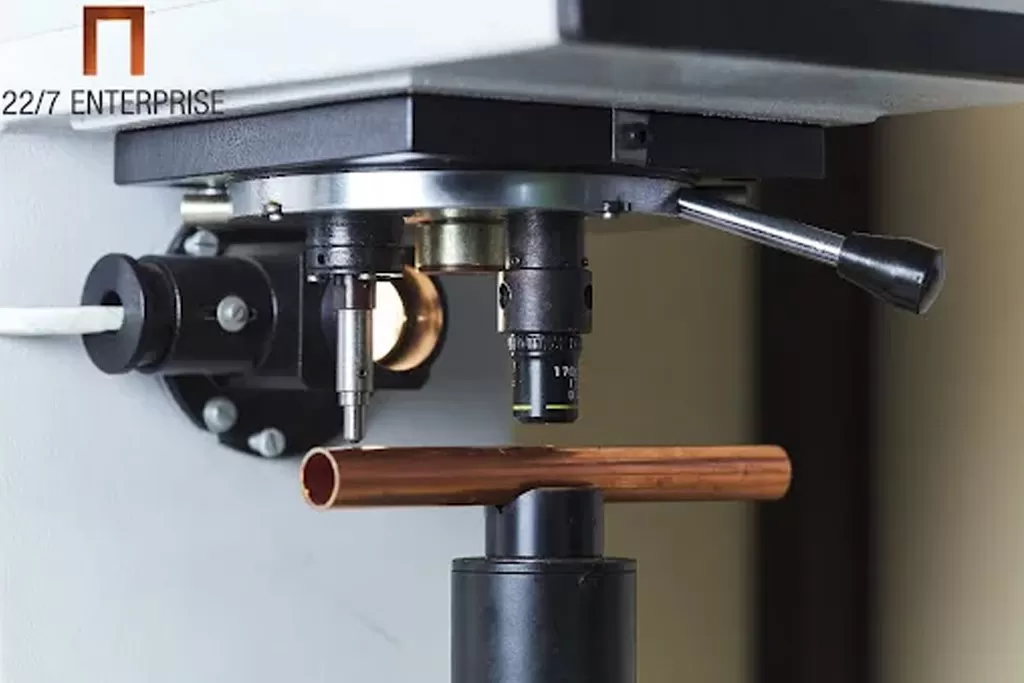

Precision Y-Joints for all VRV/VRF Systems using R410 Refrigerant

The UV‑stabilized Fire Grade XLPE insulation prevents sweating, ensures long‑term thermal stability, and offers excellent moisture and chemical resistance. Its closed‑cell structure maintains consistent insulation performance, delivering reliable, long‑lasting operation for advanced HVAC installations.

EPS

Insulation

FEATURES OF DA Series With EPS Insulation

Easy installation design

Self Locking Design

RoHS & CE compliant

Superior Thermal Efficiency

Lightweight & Easy to Handle

Product specification

| Pipe-A | Pipe-B | Pipe-C | |

|---|---|---|---|

| Pi-KHRP-22T (Gas Side) | 12.7 (1/2) – 15.88 (5/8) – 19.05 (3/4) | 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-22T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35(1/4) | 9.52 (3/8) – 6.35(1/4) |

| Pi-KHRP-33T (Gas Side) | 22.22 (7/8) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) | 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-33T (Liquid Side) | 9.52 (3/8) | 9.52 (3/8) – 6.35 (1/4) | 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-72T (Gas Side) | 31.75 (11/4) -28,58 ( 11/8) – 25.4 (1) | 25.4 (1) – 19.05(3/4) – 15.88 (5/8) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) |

| Pi-KHRP-72T (Liquid Side) | 15.81 (5/8) – 12.7 (1/2) | 12.7 (1/2) – 9.52 (3/8) | 12.7 (1/2) – 9.52 (3/8) – 6.35 (1/4) |

| Pi-KHRP-73T (Gas Side) | 38.10 (11/2) – 31.75 (11/4) | 31.75 (11/4) – 28.58 (11/8) – 25.4 (1) | 25.4 (1) – 19.05 (3/4) – 15.88 (5/8) |

| Pi-KHRP-73T (Liquid Side) | 15.88 (5/6) – 19.05 (3/4) | 19.05 (3/4) – 15.88 (5/8) – 12.7 (1/2) | 15.88 (5/8) – 12.7 (1/2) – 9.52 (3/8) |

OUR Products

Universal

Branch Pipe

Precision-engineered universal branch pipe ensuring cross-OEM compatibility and leak-proof VRF connections.

View Details

DA

Series

Precision-engineered joints and fittings designed for performance in DA Series VRF/VRV applications.

View Details

ME

Series

Reliable copper fittings engineered to meet ME Series network specifications.

View Details

MI

Series

Durable refnet joints and branch pipes crafted for reliability in MI systems.

View Details

TA

Series

Precision TA Headers and refrigerant distributors for fit in SMMS & TA Header Series

View Details

GR

Series

Specialized fittings offering corrosion resistance and leak-proof integrity for GR heat recovery systems.

View Details

BSR

Series

Pre-insulated Branch Piping Kits for streamlined, error-free installation across OEM VRF platforms.

View Details

LG

Series

Compatible copper Y-joints and distributors meeting LG Multi V system standards.

View Details

HIT

Series

Custom-tooled fittings and joints ensuring optimal compatibility for HIT Series.

View Details

HAE

Series

Robust VRF Refrigerant Branch Piping to handle pressure and demands of HAE units.

View Details

CL

Series

Precision Copper REF Joints and assemblies engineered for operation in CL conditioning systems.

View Details

LNX

Series

Certified fittings and Copper Branch Pipe systems meeting specs for LNX VRF.

View Details

PNS

Series

Accurately machined joints and pipes deliver reliability for PNS ECOi and U-Series VRF.

View Details

TRN

Series

High-performance Copper Y Fittings and piping kits engineered with TRN Series VRF systems.

View Details

VRF Y

Joint

Core VRF Y joint ensuring balanced, turbulence-free refrigerant distribution for peak efficiency.

View Details

VRF Branch

Piping

All-in-one VRF refrigerant branch piping simplifying sourcing from one trusted supplier.

View Details

VRF Refrigerant

Branch Piping

Precision routing for multi-zone VRF system distribution.

View Details

SAM

Headers

OEM-specific SAM Headers and distribution joints ensure refrigerant management in DVM S systems.

View Details

TA

Headers

Precision TA Headers and refrigerant distributors for fit in SMMS and Daiseikai series.

View Details

Customized

Headers

Bespoke Customized Header assemblies designed to meet system layouts and multi-port requirements.

View Details

Copper Compression

T Fitting

Versatile Copper Compression T Fitting engineered for leak-free branches in refrigerant line sets.

View Details

EPS

Insulation

Economical, closed-cell insulation for thermal and condensation control.

View Details

NBR

Insulation

Flexible, fire-resistant nitrile rubber insulation for demanding applications.

View Details

XLPE

Insulation

Cross-linked polyethylene foam for superior moisture and thermal resistance.

View Details

Customized

Insulation

Bespoke insulation solutions cut and tailored to your components.

View DetailsWhy 227 Enterprise

Testimonial's

The precision fit of the EPS insulation eliminated on-site modifications, saving us significant installation time.

Procurement Head, MEP Consultancy,

Saudi ArabiaSwitching to these joints noticeably improved the energy efficiency metrics in our latest hotel project.

Project Manager, HVAC Contractor,

UAEThe product quality and consistency are unmatched, which is critical for our large-scale residential developments.

Technical Director, Real Estate Developer,

India227 Enterprise provided perfectly customized sizes for a retrofit project where standard parts failed.

Service Engineer, Facility Management Company,

QatarReliable delivery and superior thermal performance have made these our default choice for VRF piping.

Owner, Air Conditioning Distributor,

OmanOur Blogs

FAq's

What is an EPS insulation and what is its purpose in VRF systems?

EPS (Expanded Polystyrene) is a closed-cell rigid foam, foamboard insulation, which is characterized by superior thermal resistance and lightweight characteristics. In VRF systems, insulating refrigerant branch junctions are required, to ensure undesirable heat transfer, to remove condensation to reinforce energy efficiency, which has a direct impact on lowering operating expenses and indirectly increases the system life.

What is the comparison of DA Series EPS insulation unto the standard XLPE insulation?

EPS insulation is usually cheaper in k-value (thermal conductivity) as compared to conventional XLPE, and has better insulating properties. This has a very high thermal gain or loss through the piping and helps the refrigerant to stay at a very accurate temperature thus improving overall system efficiency, reduces energy use, and offers improved condensation control.

Do you offer EPS insulation for VRV/VRF branch piping applications?

Yes. 227 Enterprise provides EPS insulation designed to enhance thermal efficiency and prevent condensation in VRV/VRF branch piping systems. The insulation helps maintain stable refrigerant temperatures, reduces energy loss, and supports long-term system reliability when installed as per project and environmental requirements.

What are the main advantages of your designed-insulation EPS?

We have our own specially designed EPS insulations which are pre-shaped to the exact shapes of the Y-joint to ensure a perfect fit. This helps seal all air gaps or thermal bridges and provides the system with the maximum thermal efficiency, eliminates condensation, and makes the installation of the system easy and treats it with a clean and professional finish that works throughout the lifespan of the system.

What is the method of installation of the EPS insulation on the Y-joint?

Its insulation has user friendly, pre-slitted or clam-shaped design which can be easily wrapped around the complex geometry of the joint. This strongly clamp type does not need special tools and bonding chemicals to be fastened there and thus can be installed very fast and without errors on-site that would save precious labor time and provide uniform, gap-free insulation cover.

What are the quality and safety requirements of your products?

Our products come under strict test and joints under pressure testing of up to 5.2 MPa. The EPS insulation is also fire-resistant, compliant with ASTM E84 on low flame spread and smoke density, and also RoHS and CE compliant, which means that they are highly consistent in terms of safety, environmental responsibility, and performance with high International standards.

How long is the lead time of orders?

For customized specifications or bulk orders, we provide a specific timeline after reviewing your detailed requirements. We prioritize open communication and will work with your project's critical path to establish a mutually agreeable schedule that meets your installation deadlines.

How long is the lead time of orders?

In the case of a conventional DA Series item, we normally have a 7-10 day dispatch lead time. In case of customized or bulk orders, we will give you a particular timeline after you present your detailed requirements and we will maintain a communication line with this and a good schedule to match your project critical path and deadlines of setups.

Does it provide warranty support on the DA Series with EPS insulation?

Yes, we do offer a full warranty on materials and workmanship on the DA Series. We can ensure that the copper joints and EPS insulation will be defect free and will meet intended performance in the typical conditions of operation with our warranty that will be supported by our quality and customer services.

What is the relationship between energy saved in a VRF system with the use of EPS insulation?

With the minimization of thermal transfer, EPS insulation helps in reducing the workload of the system to cover the heat gain/loss. This reduces the compressor energy requirements by a large margin increasing the Coefficient of Performance (COP). The outcome will be an immediate decrease in the electricity consumption and operational expenses which will provide a high payoff on the investment over the lifespan of the system.